High-precision current monitoring and processing system

A current monitoring, high-precision technology, applied in the direction of only measuring current, voltage/current isolation, measuring current/voltage, etc., can solve the problems of low reliability and low practicability, so as to improve equipment integration, improve processing speed, The effect of reducing the number of probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

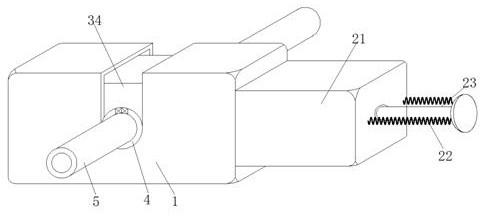

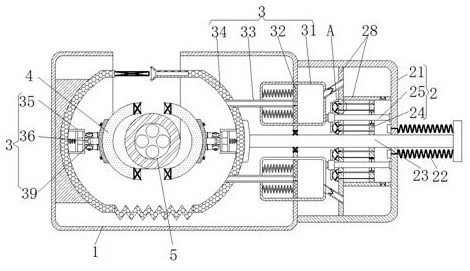

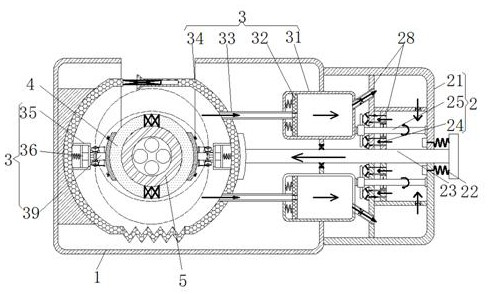

[0037] see Figure 1-8, a high-precision current monitoring and processing equipment, including a monitoring mechanism 3, the monitoring mechanism 3 includes a casing-31, the inside of the casing-31 is slidably connected to a piston-32, and the inside of the piston-32 is fixedly connected to a connecting pipe-33 , the end of the connecting pipe one 33 away from the piston one 32 is fixedly connected with the shell two 34, the inner wall of the shell two 34 is fixedly connected with the sliding shell one 35, the inside of the sliding shell one 35 is fixedly connected with the polarizer 36, the sliding shell one The inside of 35 is fixedly connected with magneto-optical element 37, the outer surface of sliding shell-35 is rotatably connected with analyzer 38, and the inside of sliding shell-35 is slidably connected with piston rod-39. Therefore, the magneto-optical element 37 passes through effect, the current of the cable 5 can be quickly monitored in real time without damaging...

Embodiment 2

[0039] see Figure 1-8 , a high-precision current monitoring and processing equipment, including a monitoring mechanism 3, the monitoring mechanism 3 includes a casing-31, the inside of the casing-31 is slidably connected to a piston-32, and the inside of the piston-32 is fixedly connected to a connecting pipe-33 , the end of the connecting pipe one 33 away from the piston one 32 is fixedly connected with the shell two 34, the inner wall of the shell two 34 is fixedly connected with the sliding shell one 35, the inside of the sliding shell one 35 is fixedly connected with the polarizer 36, the sliding shell one The inside of 35 is fixedly connected with magneto-optical element 37, the outer surface of sliding shell-35 is rotatably connected with analyzer 38, and the inside of sliding shell-35 is slidably connected with piston rod-39. Therefore, the magneto-optical element 37 passes through effect, the current of the cable 5 can be quickly monitored in real time without damagin...

Embodiment 3

[0041] see Figure 1-8 , a high-precision current monitoring and processing equipment, including a monitoring mechanism 3, the monitoring mechanism 3 includes a casing-31, the inside of the casing-31 is slidably connected to a piston-32, and the inside of the piston-32 is fixedly connected to a connecting pipe-33 , the end of the connecting pipe one 33 away from the piston one 32 is fixedly connected with the shell two 34, the inner wall of the shell two 34 is fixedly connected with the sliding shell one 35, the inside of the sliding shell one 35 is fixedly connected with the polarizer 36, the sliding shell one The inside of 35 is fixedly connected with magneto-optical element 37, the outer surface of sliding shell-35 is rotatably connected with analyzer 38, and the inside of sliding shell-35 is slidably connected with piston rod-39. Therefore, the magneto-optical element 37 passes through effect, the current of the cable 5 can be quickly monitored in real time without damagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com