Device and method for testing throttling coefficient of carbon dioxide fracturing fluid

A technology of throttling coefficient and carbon dioxide, which is applied in the preparation of test samples, instruments, analysis materials, etc., can solve the problems of insufficient pressurization of fracturing fluid, complexity, large deviation of throttling coefficient, etc. The effect of test efficiency and accurate measurement value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

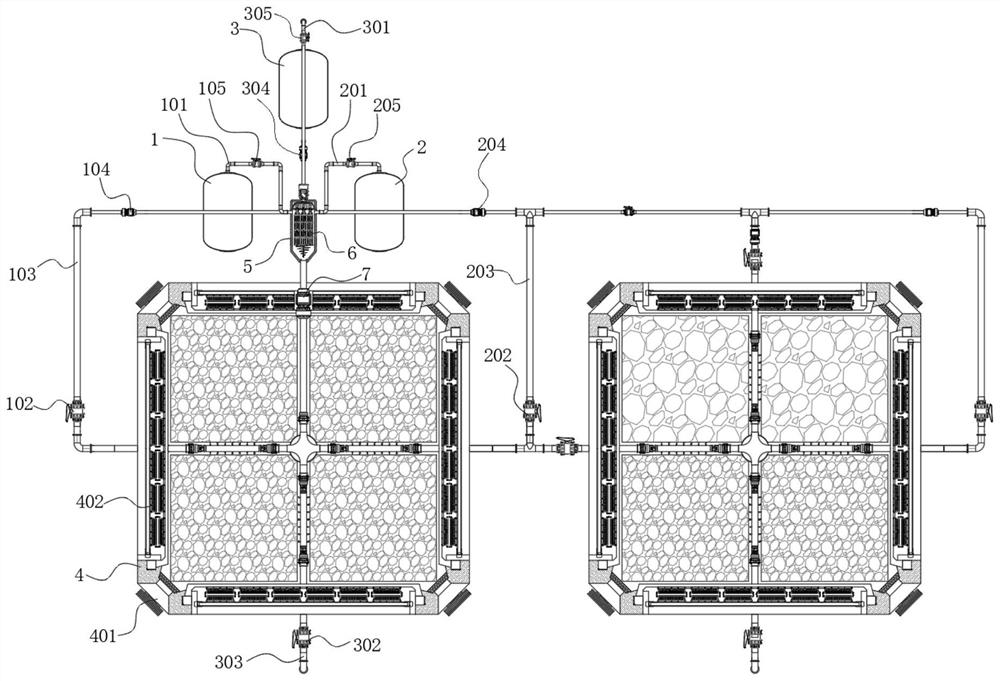

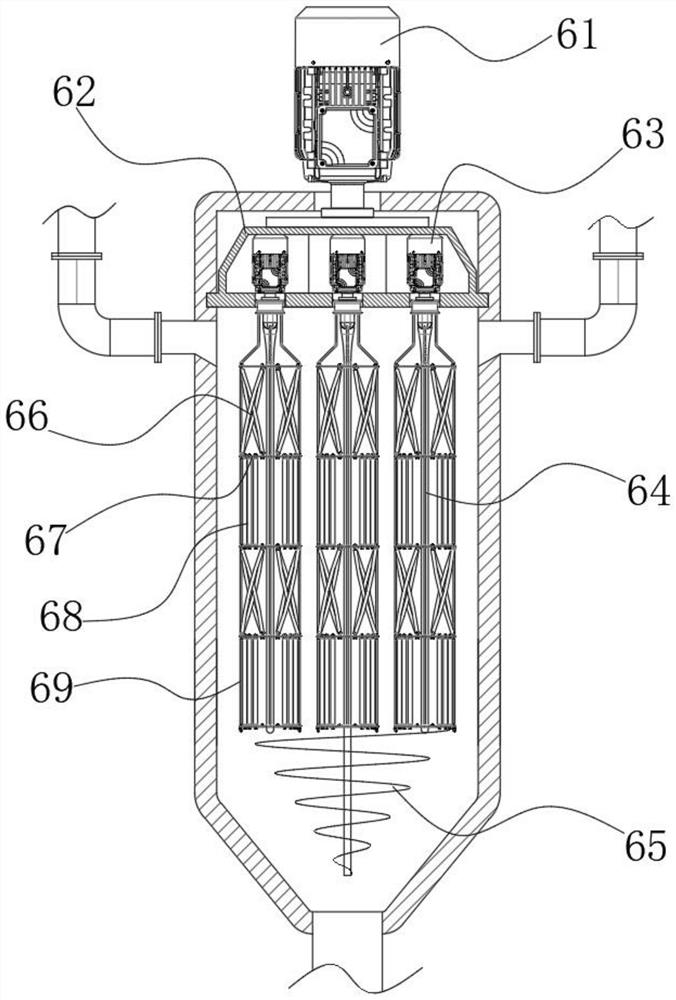

[0038] refer to Figure 1-3 , the present invention provides a technical solution: a test device for the throttling coefficient of carbon dioxide fracturing fluid, which includes a liquid carbon dioxide injection device 1, a fracturing fluid base fluid injection device 2, a proppant injection device 3, and a first simulation test box 4 and a mixed foaming tank 5, the liquid carbon dioxide injection device 1, the fracturing fluid base liquid injection device 2, and the proppant injection device 3 pass through the first introduction pipe 101, the second introduction pipe 201, the third introduction pipe 301 and the The mixing and foaming tanks 5 are connected, and the connected end faces are located at the tank wall near the upper end side of the mixing and foaming tank 5, and a foaming assembly 6 is installed inside the mixing and foaming tank 5;

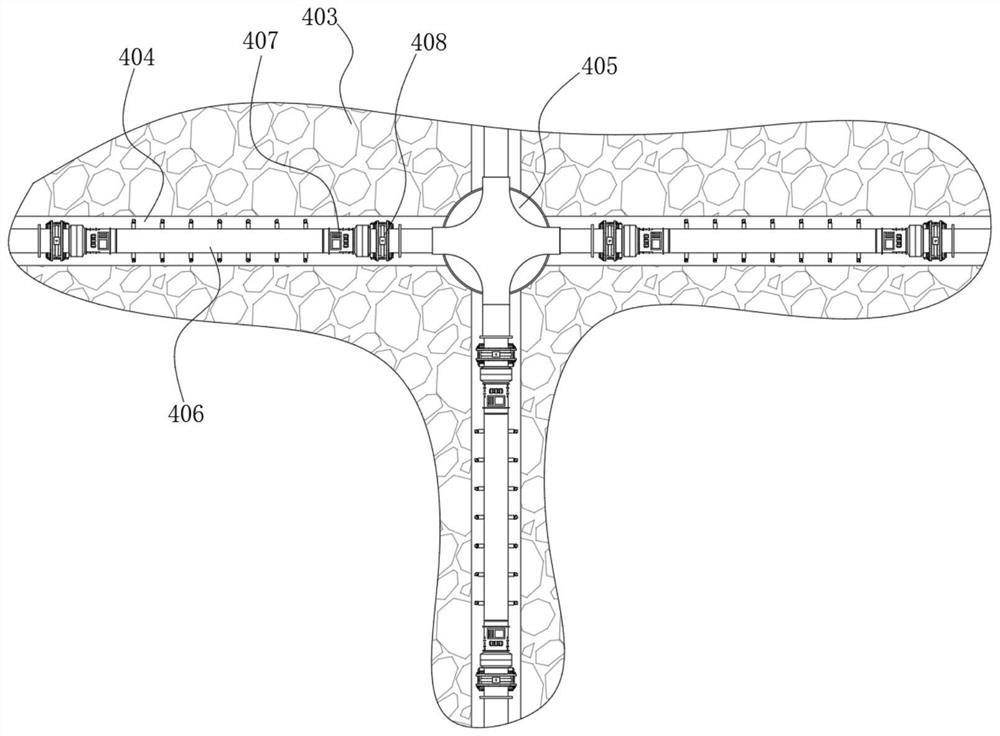

[0039] The first simulated test box 4 is provided with a simulated well 404, which is in a cross structure, and its internal space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com