Engine input end shafting bearing testing machine and testing method

A bearing test and input-side technology, applied in mechanical bearing testing, aircraft component testing, etc., can solve the problems of high equipment input cost, low test efficiency, synchronous testing, etc., and achieve compact equipment structure, high test efficiency, and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

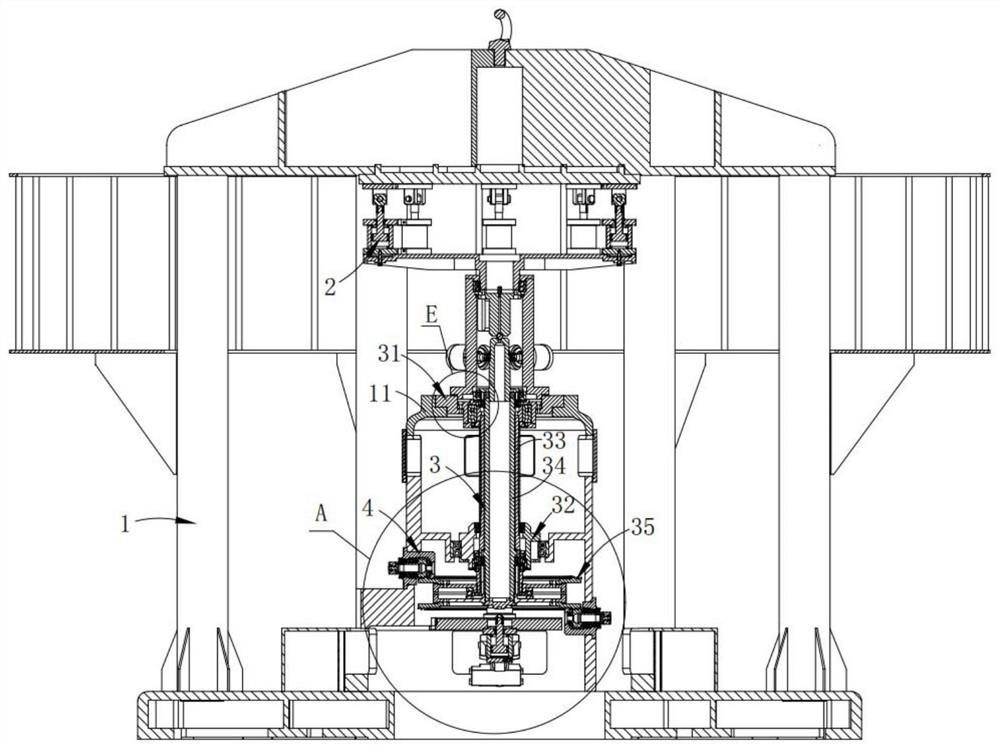

[0067] Such as Figure 1-2 As shown, a shaft bearing test machine at the input end of the engine includes:

[0068] A frame 1, the frame 1 is provided with a host casing 11;

[0069] Loading system 2, the loading system 2 is arranged below the top of the frame 1;

[0070] A dual-rotor system 3, the dual-rotor system 3 is arranged in the main engine housing 11 and connected to the output end of the loading force of the loading system 2; the dual-rotor system 3 includes a rotor power unit 35; and

[0071] Input-end bearing test system 4, the input-end bearing test system 4 is installed on the main engine housing 11 and connected with the rotor power unit 35 transmission; wherein, the input-end bearing test system 4 is provided with two groups, and respectively Be connected with the upper and lower ends of the rotor power unit 35;

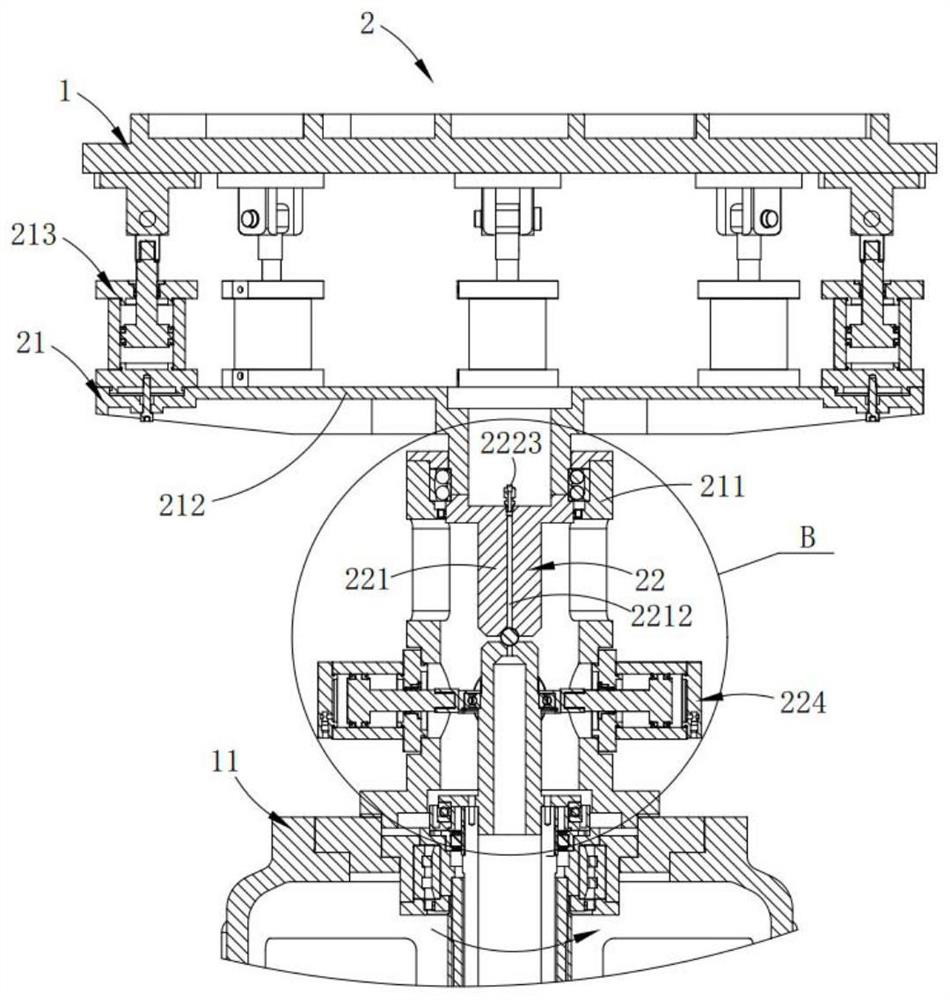

[0072] The loading system 2 includes:

[0073] A propeller simulation system 21, the upper end of the propeller simulation system 21 is connected...

Embodiment 2

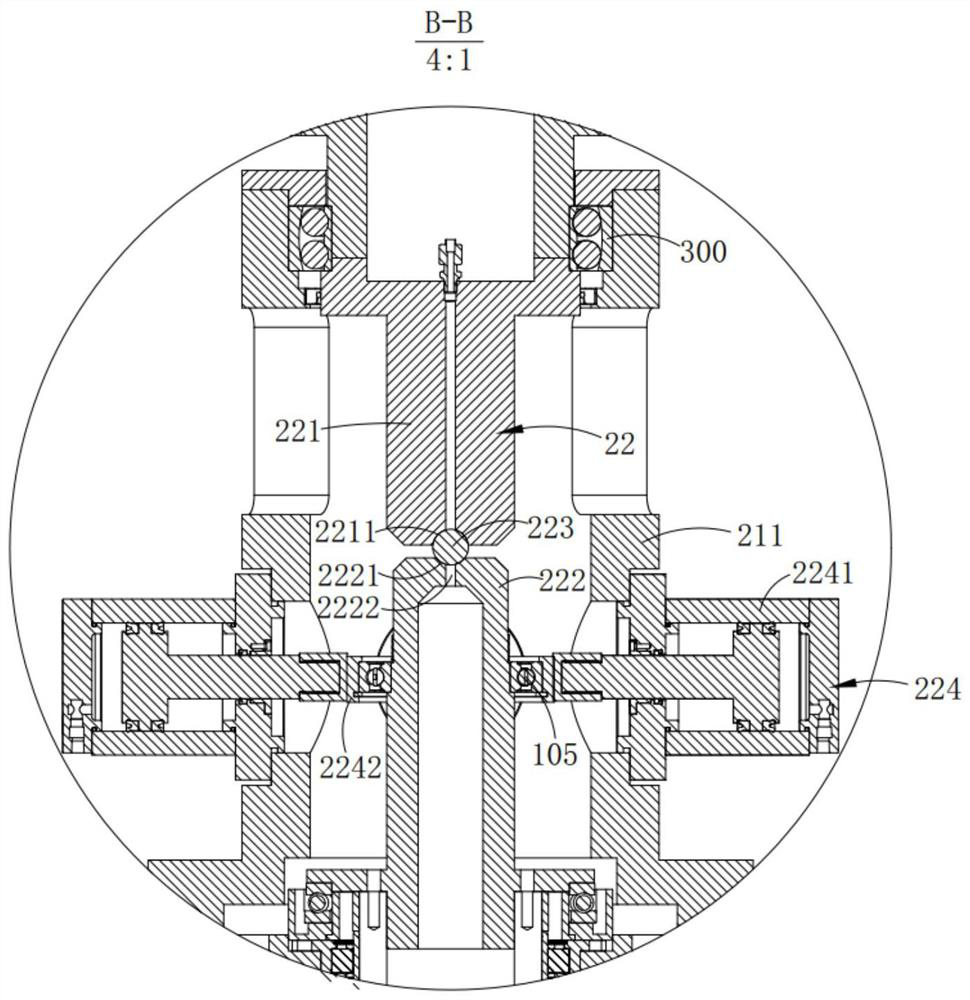

[0101] Such as figure 1 , 5 , 7-10, wherein the same or corresponding components as those in the first embodiment use the corresponding reference numerals as in the first embodiment, for the sake of brevity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is:

[0102] In this example, if figure 1 As shown, the dual-rotor system 3 includes:

[0103] An upper transition assembly 31, the upper transition assembly 31 is connected to the upper part of the main body casing 11;

[0104] a lower transition assembly 32, the lower transition assembly 32 is connected to the bottom of the main body housing 11;

[0105]Hollow outer rotor shaft 33, the upper end of the hollow outer rotor shaft 33 is connected to the connecting seat 313 of the upper transition assembly 31, the lower end of the hollow outer rotor shaft 33 and the lower transition assembly 32 pass through the first test bearing 101 is rotati...

Embodiment 3

[0135] Such as Figure 5-6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment three and embodiment one is:

[0136] In this example, if Figure 5-6 As shown, the input end bearing testing system 4 includes:

[0137] An output bearing seat 41, the output bearing seat 41 is installed on the main engine casing 11 for installing the sixth test bearing 106; and

[0138] Transmission shaft 42, the transmission shaft 42 is connected with the inner ring of the sixth test bearing 106, one end of which is provided with a small bevel gear 421; the small bevel gear 421 is transmission connected with the rotor power unit 35.

[0139] Wherein, the bevel pinion gear 421 in one set of input end bearing test system 4 is in drive conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com