Range extender system output torque verification method

A technology of output torque and calibration method, applied in the direction of force/torque/work measuring instrument calibration/test, instruments, measuring devices, etc., can solve the problems of range extender engine torque model deviation, affecting the accuracy of torque control, etc. Achieve the effect of increasing monitoring means, improving precision and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

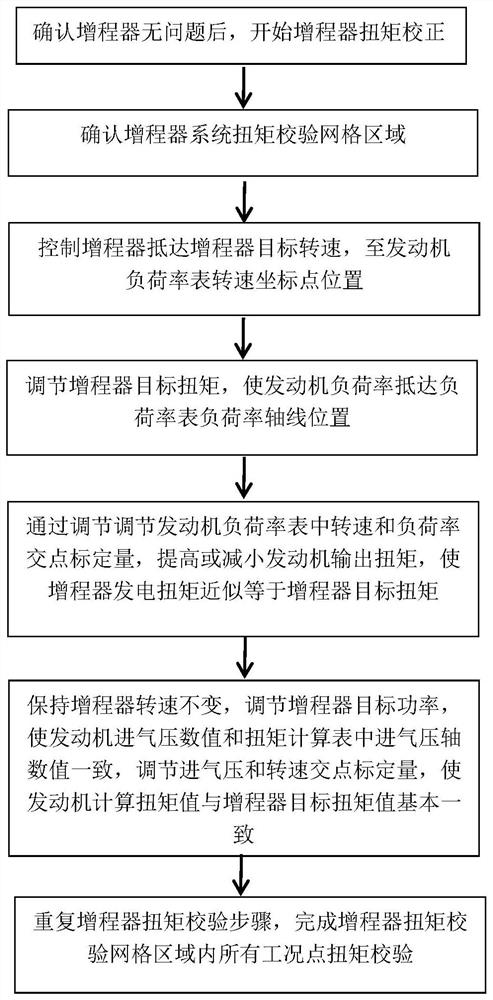

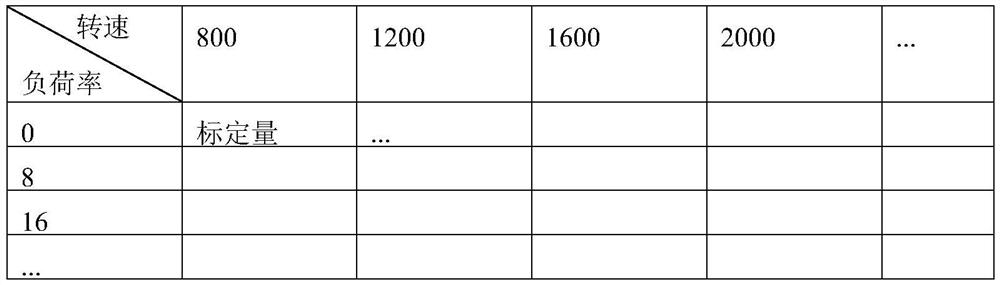

[0018] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-2 , the present invention is described in further detail.

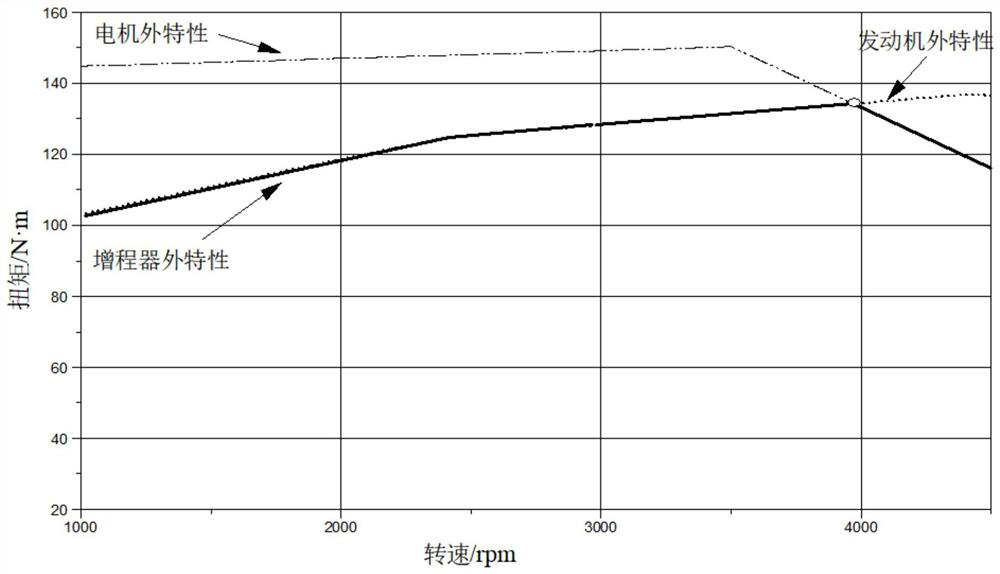

[0019] The invention includes the unified calibration of the target torque of the range extender, the output torque of the range extender and the calculated torque of the engine. The invention takes the target torque as a reference, calibrates the output torque of the engine at the target speed, and the calculated torque of the engine is consistent with the target torque of the range extender, so as to realize the precise operation of the range extender. Both the calculated torque of the engine and the calculated torque of the generator (power generation torque) are calculated from their respective operating parameters. When the torque deviates, the abnormal operation of the range extender can be detected in time, the operating efficiency of the range extender can be improved,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com