LED lamp with graphene heat conduction layer

A technology of LED lamps and thermal conductive layers, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problems of poor heat dissipation effect, etc. The effect of the overall cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

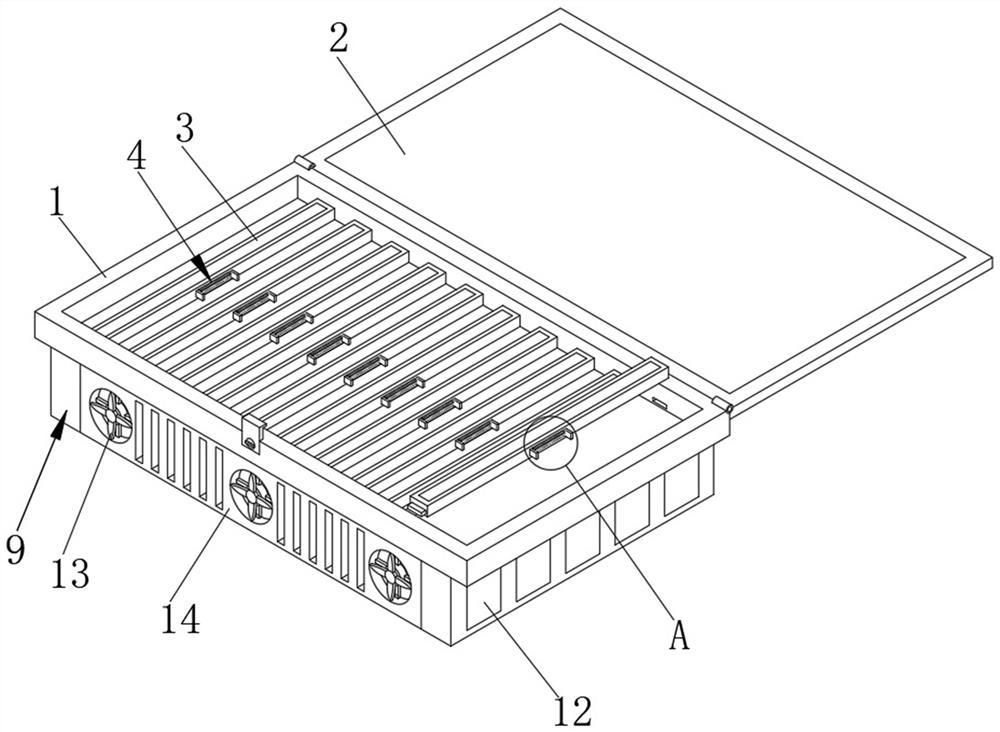

[0030] Embodiment 1: When the LED light bar 3 needs to be replaced, the present invention provides such figure 2 , Figure 4 , Figure 7 In the shown LED lamp with a graphene heat-conducting layer, an installation cavity is provided inside the installation box 1 , and a plurality of LED light strips 3 are clamped and installed in the installation cavity through a clamping structure 4 .

[0031] Specifically, one side of the LED light bar 3 is provided with a cavity for the installation of the snap-in structure 4. The snap-in structure 4 includes a plug-in rod 5 for auxiliary insertion and a guide rod 7 for auxiliary guiding and sliding. The snap-in structure 4 can After the light bar is damaged, it is convenient and quick to replace the light bar. The guide rod 7 is installed in the cavity, and the ejection spring 8 is sleeved on the guide rod 7. The setting of the ejection spring 8 can push the push plate under normal conditions. 6 to carry out a good push, and then ensure...

Embodiment 2

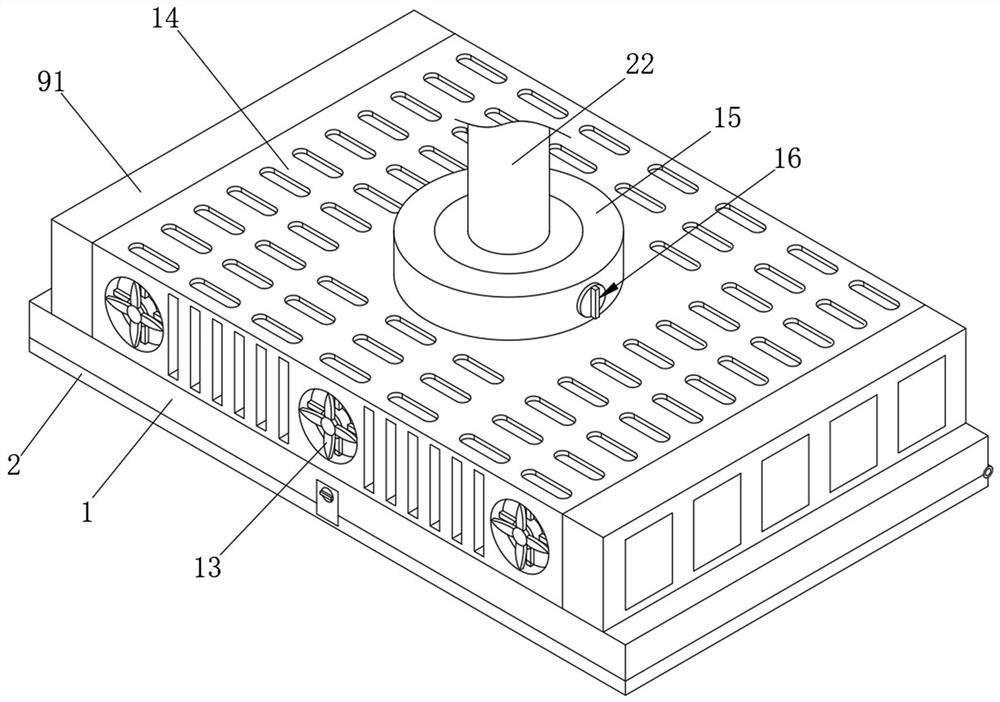

[0034] Embodiment 2: when the cooling box 14 needs to be dismantled, the present invention provides such figure 1 , image 3 As shown in an LED lamp with a graphene heat-conducting layer, a mounting cylinder 15 is installed on the top of the cooling box 14, and the mounting cylinder 15 is clamped and mounted on the fastening plate 22 through the fastening structure 16, and the fastening plate 22 is round. It is disc-shaped and has a fixed rod fixed on the top.

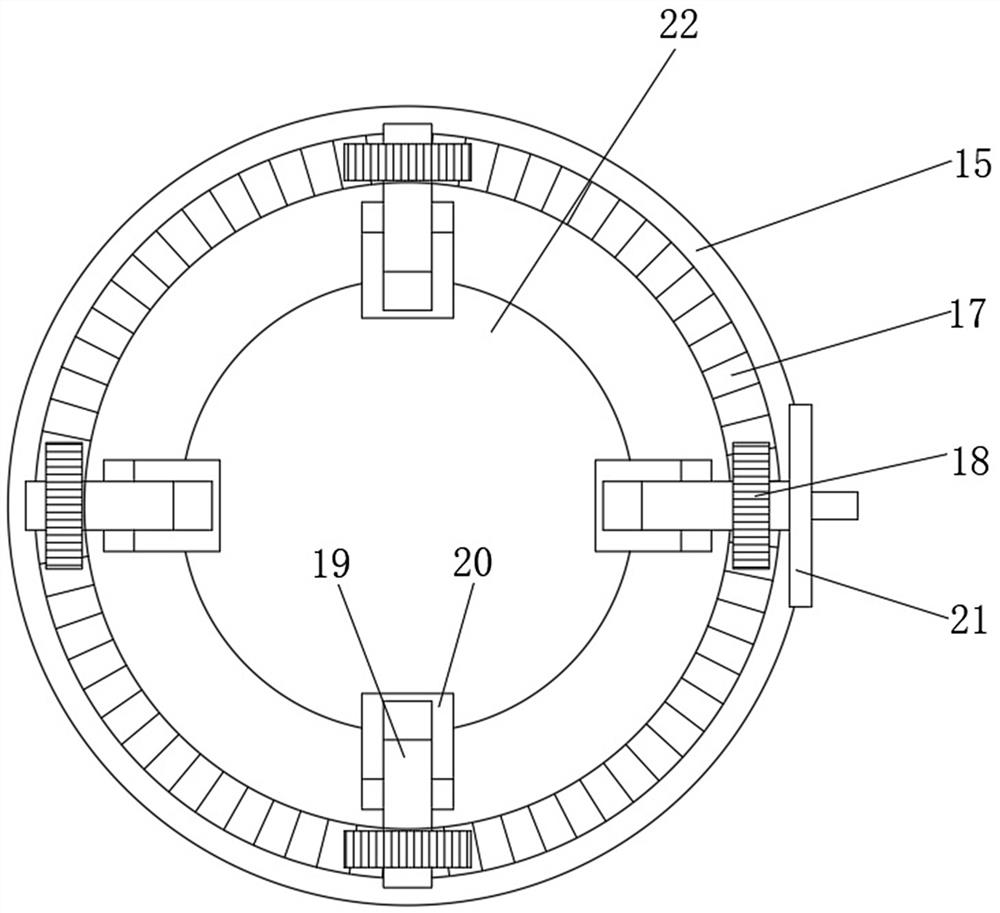

[0035] Specifically, the fastening structure 16 includes a threaded rod 19, an inserting block 20 mated with the threaded rod 19, and an engagement ring 17 that assists in adjusting the rotation of several threaded rods 19. The fastening structure 16 can be used for maintenance of LED lamps, etc. It is convenient to quickly disassemble and remove the cooling box 14 etc., and then it is convenient to overhaul the device. The meshing ring 17 is disc-shaped, and is rotatably embedded and installed inside the installation...

Embodiment 3

[0038] Embodiment 3: when it is necessary to dissipate heat inside the device, the present invention provides such figure 1 , figure 2 , Figure 5 , Image 6 In the shown LED lamp with a graphene heat-conducting layer, a cover plate 2 is hingedly installed at the bottom of the installation box 1, and the cover plate 2 and the installation box can be fastened and fixed by bolts, and the top of the installation box 1 is installed Radiating box 14 is arranged, and cooling structure 9 is all arranged on the two parallel sides of cooling box 14, and cooling fan 13 for heat radiation is installed on both sides of cooling box 14 away from cooling structure 9, and cooling box 14 inside is provided with There are several air guide fins 141, and several air outlet holes are provided at the top of the cooling box 14, and the air outlet holes are elliptical to facilitate air exhaust.

[0039] Specifically, several air guide vanes 141 protrude and are fixed on the top of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com