Emergency suspension device for seabed sonar robot

A suspension device and robot technology, which is used in motor vehicles, transportation and packaging, special-purpose ships, etc., can solve the problems of equipment detachment, device damage, and the suction cup is prone to misoperation, and achieves the effect of increasing the adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

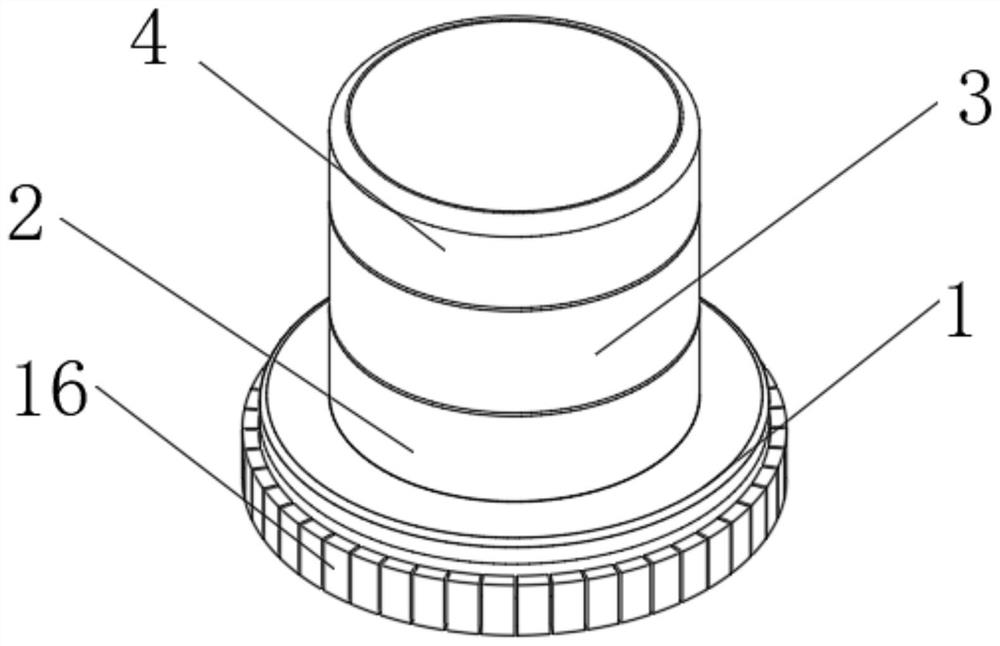

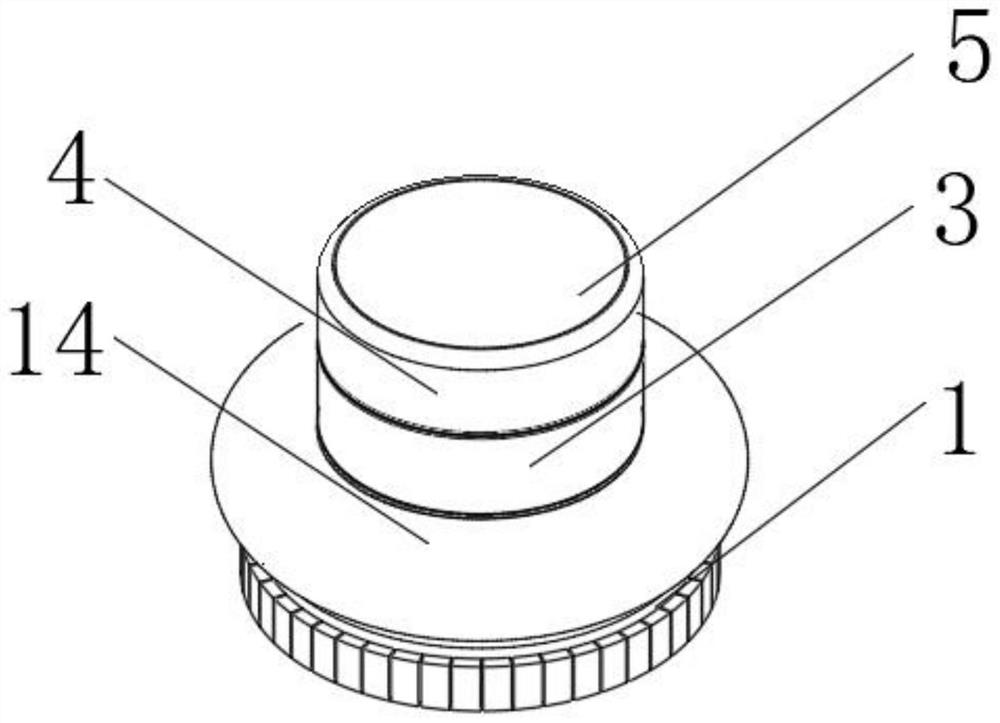

[0027] Embodiment 1, with reference to Figure 1-6 As shown, an emergency suspension device for a submarine sonar robot includes: a connecting base 1, the top of which is sequentially connected with a cylindrical support tube 2, a connecting ring 3 and a top cover 4 from bottom to top, and on the connecting ring 3 The bellows 5 is connected with the top cover 4, and a folded airbag cover 14 is arranged between the connecting ring 3 and the support cylinder 2, and the airbag cover 14 is located in the low-pressure area.

[0028] The slow-rising mechanism includes the No. 1 self-locking motor 6 installed on the inner top surface of the top cover 4 and the mounting seat 8 installed on the inner wall of the connecting ring 3, and the No. 1 screw rod 7 installed on the output shaft of the No. 1 self-locking motor 6 It is threadedly connected with the threaded cylinder 9 installed at the center of the mounting seat 8, and an air bag is arranged between the top cover 4 and the connec...

Embodiment 2

[0051] Embodiment 2, with reference to Figure 1-6 As shown, an emergency suspension device for a submarine sonar robot includes: a connecting base 1, the top of which is sequentially connected with a cylindrical support tube 2, a connecting ring 3 and a top cover 4 from bottom to top, and on the connecting ring 3 The bellows 5 is connected with the top cover 4, and a folded airbag cover 14 is arranged between the connecting ring 3 and the support cylinder 2, and the airbag cover 14 is located in the low-pressure area.

[0052] The slow-rising mechanism includes the No. 1 self-locking motor 6 installed on the inner top surface of the top cover 4 and the mounting seat 8 installed on the inner wall of the connecting ring 3, and the No. 1 screw rod 7 installed on the output shaft of the No. 1 self-locking motor 6 It is threadedly connected with the threaded cylinder 9 installed at the center of the mounting seat 8, and an air bag is arranged between the top cover 4 and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com