Hollow plate edge cutting material on-line granulator

A granulator and edge trimming technology, which is applied in the field of online granulator for hollow plate edge trimming, can solve the problems of inability to granulate raw materials, insufficient "granule" rate, and reuse, etc., to solve the problem of low "granule" rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

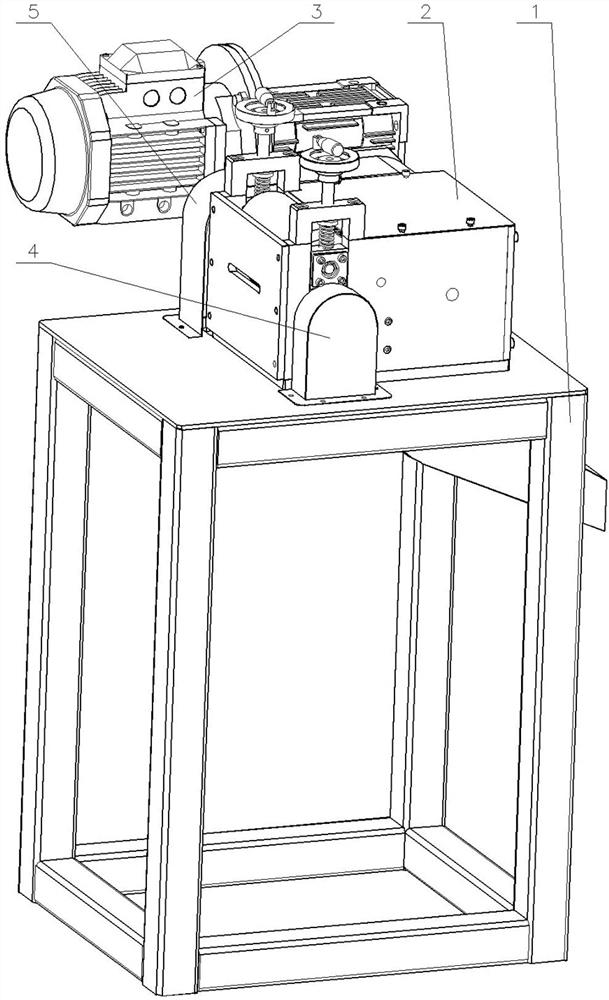

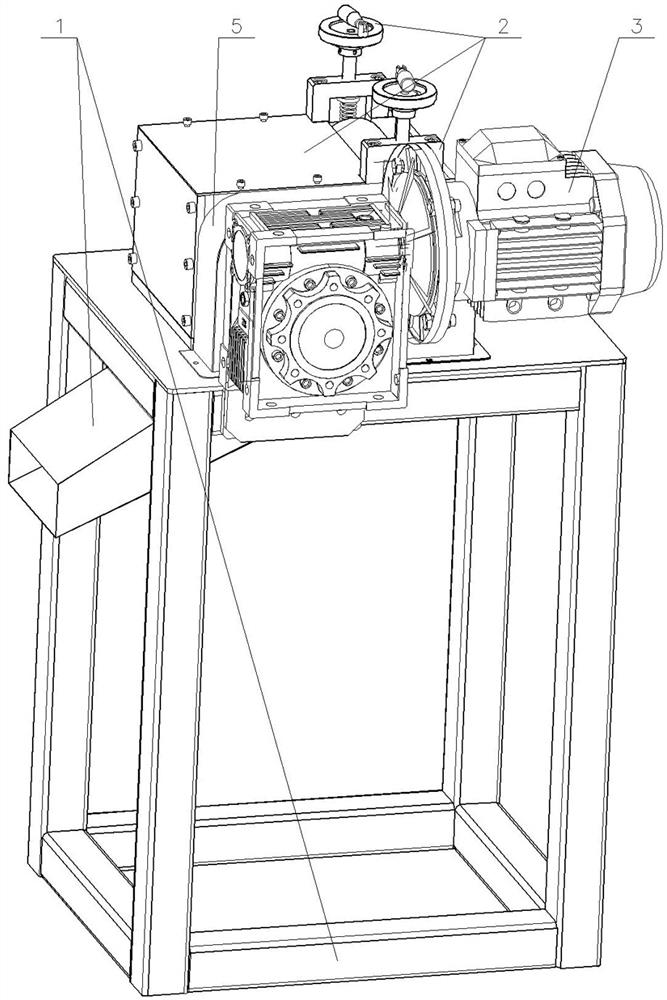

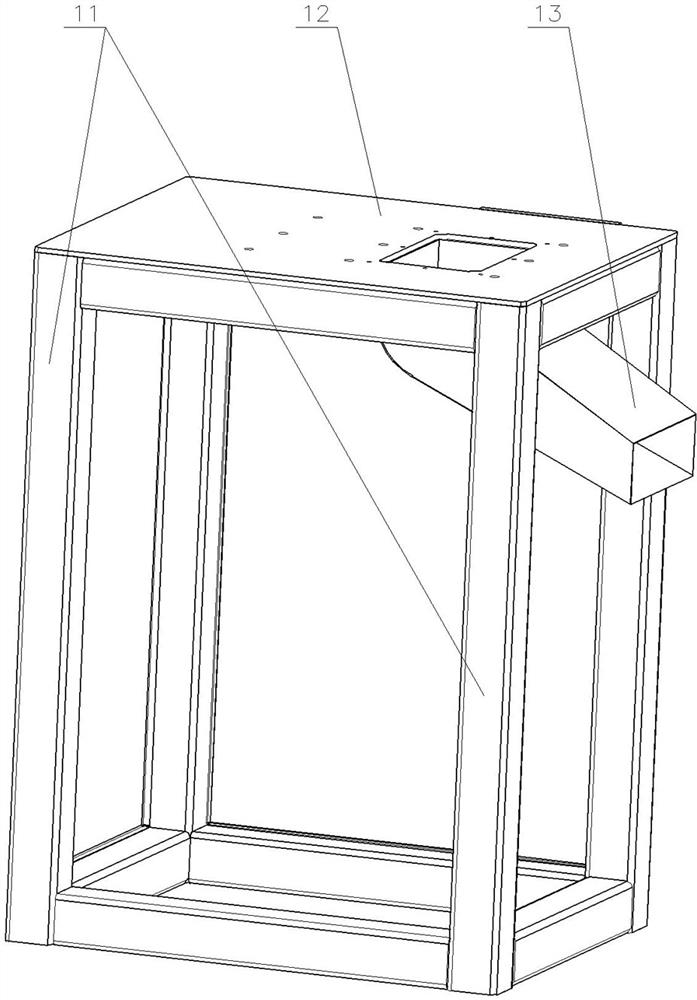

[0035] 1. Rack 11, frame 12, supporting plate 121, discharge hole 13, discharge funnel 2, granulation device 21, granulation box 211, side plate 2111, U-shaped groove 212, blocking plate I 2121, feed port 213, blocking plate II 214, cover plate 215, U-shaped frame 216, right-angle frame 217, backing plate 22, transmission assembly 221, transmission shaft 222, driven sprocket I 223, driving gear 23, feed assembly 231, feed Roller 232, driven gear 24, pressing assembly 241, pressing roller 242, slide block 243, screw rod 244, stage clip 245, adjustment handle 25, cutting assembly 251, cutting shaft 252, cutting moving knife 253, spacer Ring 254, driven sprocket II 255, slitting fixed knife 26, granulation assembly 261, granulation moving knife 262, granulation shaft 263, driving sprocket 264, granulation fixed knife 2641, fixed knife edge 27, chain 3, Driving device 31, speed-regulating motor 32, mounting plate 4, gear shield 5, chain wheel shield.

[0036] exist Figure 1-Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com