Side chain blocking block automatic and synchronous running device and method of dual-track type forming machine

An automatic synchronization and operation device technology, applied in the field of mechanical synchronization, can solve the problems of unreliability and high cost, and achieve the effects of stable operation, prolonging service life, improving reliability and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention.

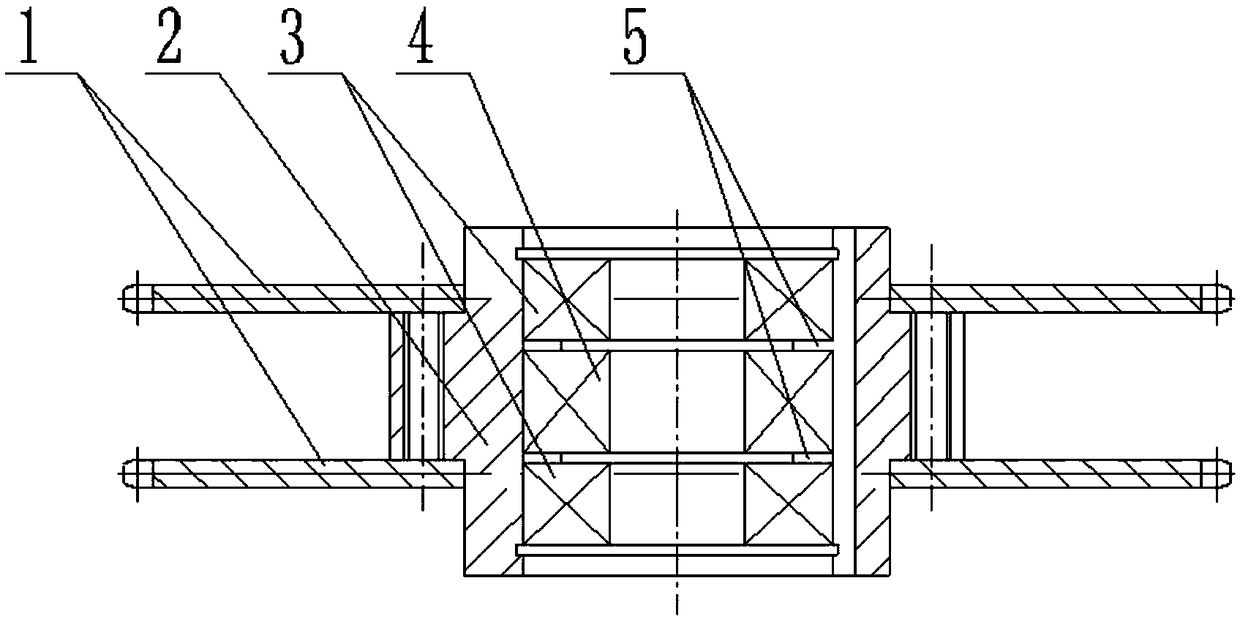

[0022] figure 1 The schematic diagram of the automatic synchronous operation device for the side chain block of the double crawler type forming machine provided in this embodiment, the automatic synchronous operation device for the side chain block of the double crawler type forming machine consists of a sprocket 1, a sprocket seat 2, a bearing 3, Cam clutch 4, gasket 5 and other components are composed.

[0023] Sprocket 1 is fixedly installed on the sprocket seat 2 by bolts, and bearing 3, spacer 5, cam clutch 4, spacer 5 and bearing 3 are installed successively in the chain wheel seat 2 from top to bottom. The outer circumference of the cam clutch 4 is connected with the sprocket seat 2 by a key.

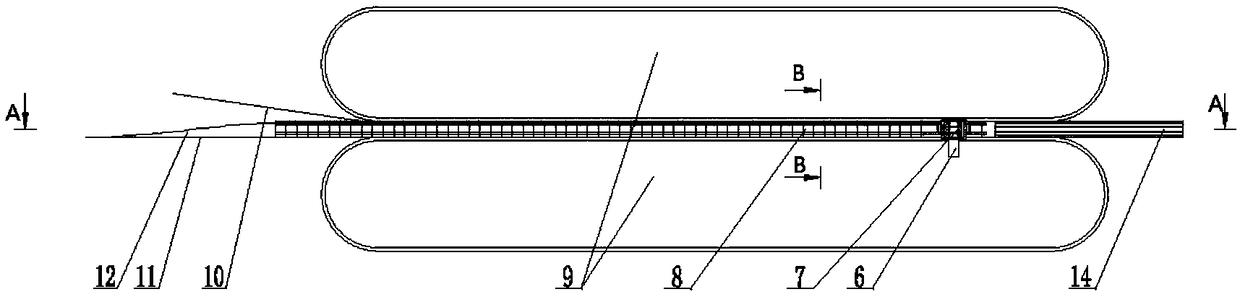

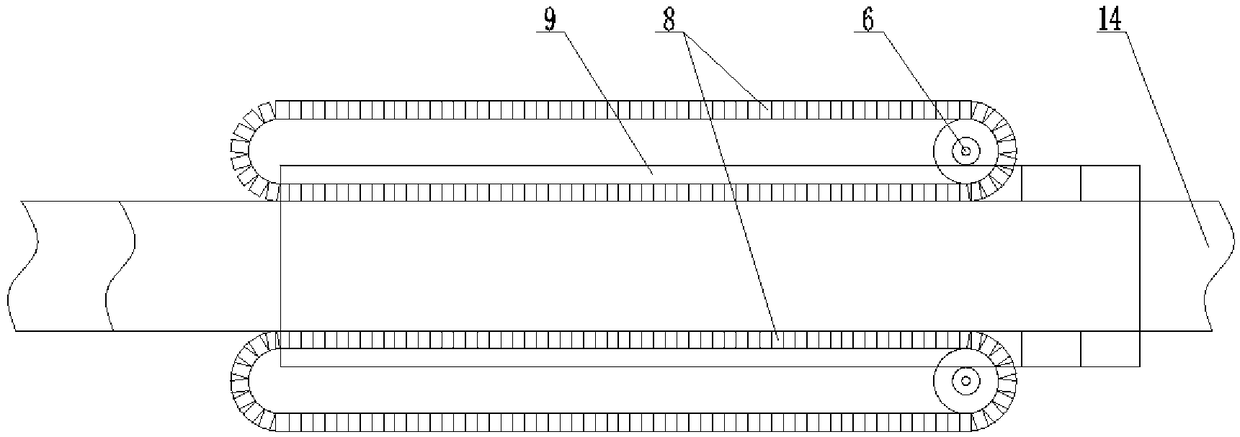

[0024] Such as Figure 2 ~ Figure 4 As shown, the main engine of the double crawler forming machine includes upper and lower crawlers 9 and left and right side chains. The inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com