A fine metal wire drawing device

A metal wire drawing and wire drawing technology, which is applied in the field of metal wire drawing, can solve the problems of manpower consumption, slow work efficiency, and large size of wire drawing equipment, and achieve the effects of strengthening the clamping effect, reducing labor force, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

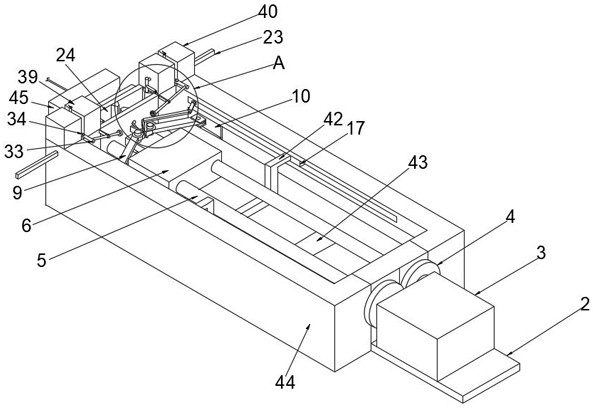

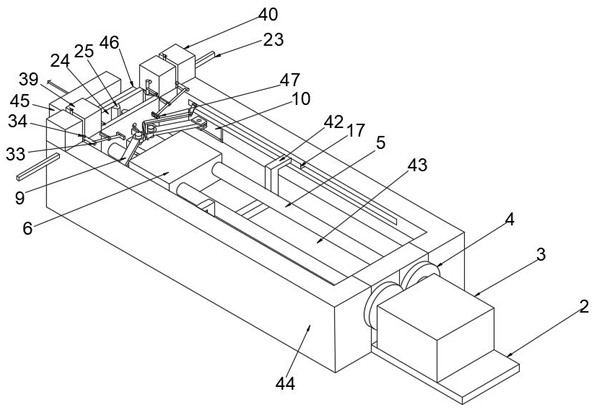

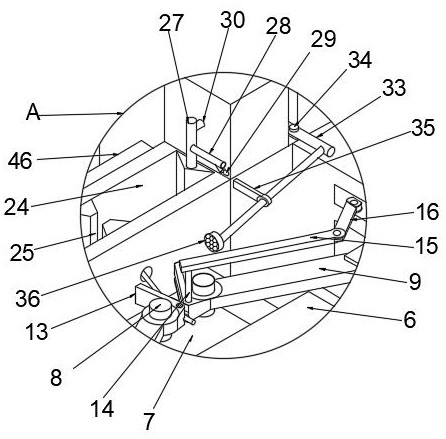

[0032] see Figure 1 to Figure 10 , the present invention provides a technical solution: a fine metal wire drawing device, including a base 1, the left and right sides of the base 1 are fixedly connected with side plates 44, the front side of the base 1 is provided with a heating box 45, the base 1 The top of the top is provided with a wire drawing device 48 that automatically clamps and automatically draws the thin metal wire; the wire drawing device 48 includes a motor 3, the bottom of the motor 3 is fixedly connected to a base 2, and the base 2 is fixedly connected to the rear side of the base 1. The rear side of the base 1 is connected with two sets of rotating wheels 4 that are meshed and connected to each other. The output end of the motor 3 is fixedly connected to the side of the rotating wheels 4 away from the base 1, and the two sets of rotating wheels 4 are on the side close to the base 1. The screw rod 5 is fixedly connected, and the limit of the screw rod 5 runs th...

Embodiment 2

[0037] see figure 1 , figure 2 and Figure 9 , the cleaning device 50 includes two groups of fixed rods 27, the two groups of fixed rods 27 are fixedly connected to the top of the cutter 26 respectively, the tops of the fixed rods 27 are fixedly connected with the piston rod 30 on the side away from each other, the rear side of the fixed rods 27 is fixed An air jet pipe 28 is connected, and the bottom of the air jet pipe 28 is connected with an air guide pipe 29, and the end of the air guide pipe 29 away from the air jet pipe 28 is connected with an air-dry box 39, and the outside of the air-dry box 39 is provided with a water cooling box 40, and the water cooling box 40 and The bottoms of the air-drying box 39 are all fixedly connected to the tops of two groups of side plates 44, and the piston rod 30 runs through the air-drying box 39 and the water-cooling box 40 in turn and is fixedly connected with a first piston plate 31 and a second piston plate 32, and the first pisto...

Embodiment 3

[0040] It is basically the same as Embodiment 2, the difference is that in this embodiment, the first nozzle 36 is replaced by the second nozzle 47, thereby increasing the spraying area of the spraying water flow from the nozzle and speeding up the spray cooling of the nozzle to the metal wire Effect.

[0041] see Figure 6 , the sides of the pressure plates 13 close to each other are provided with anti-slip structure and groove structure, which is beneficial to wrap and tighten the thin metal wire through the groove structure, increase the contact surface between the pressure plate 13 and the thin metal wire, and then lift the pressure plate 13 The clamping force on the metal wire is combined with the anti-skid pattern to further improve the stability of the wire drawing device 48 clamping the thin metal wire.

[0042] see Figure 4 , both sides of the first support plate 10 and the second support plate 12 are set as arc-shaped surfaces, the depth of the front end in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com