Processing method of black tea with glutinous and sweet flower fragrance

A processing method and technology for black tea, applied in the processing of waxy sweet floral black tea and in the field of tea processing, can solve the problems affecting the market prospects and economic benefits of the black tea industry, not establishing a raw material base for black tea, insufficient aroma and flavor of black tea, etc., so as to promote mass production. , enriching aroma and taste characteristics, ensuring uniformity and uniformity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

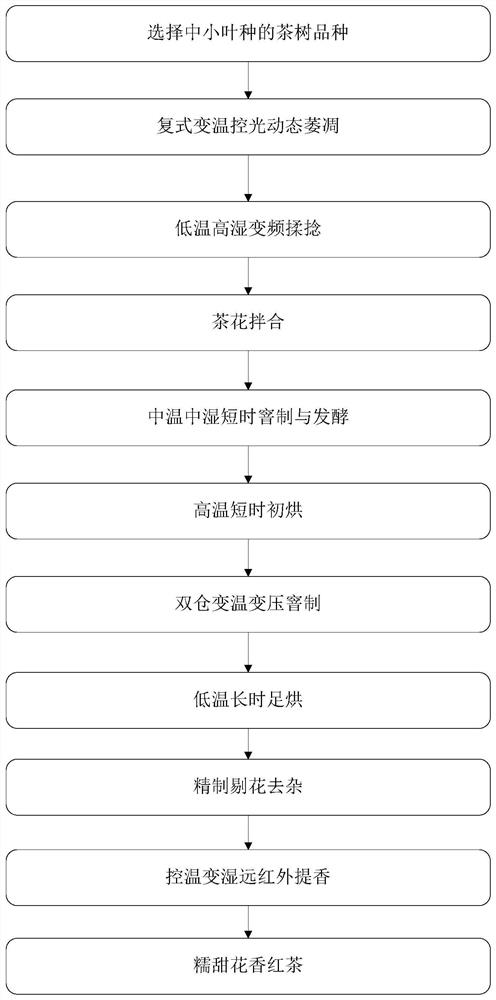

[0038] Such as figure 1 Shown, a kind of processing method of glutinous sweet floral black tea comprises:

[0039] (1) Picking the fresh leaves of the tea tree species suitable for making black tea as a raw material, wherein:

[0040] The small and medium-sized tea tree varieties suitable for making black tea include Jiukeng, Fuding Dabai, Quyeqi, Qimen Chuyezhong, and Huangguanyin;

[0041] (2) Place the fresh leaves picked in step (1) into a continuous withering system for dynamic withering treatment with variable temperature and light control, and wither until the leaf moisture content is 60% to obtain withered leaves, wherein:

[0042] The relative humidity of the environment is controlled at 65%, and the thickness of the spread leaves is 2cm. The compound withering combination of hot air red light withering and cold air white light withering is alternately used to fully promote the increase of soluble sugar and amino acid content in the leaves. The dynamic operation on ...

Embodiment 2

[0060] A processing method for glutinous sweet floral black tea, comprising:

[0061] (1) Picking the fresh leaves of the tea tree species suitable for making black tea as a raw material, wherein:

[0062] The small and medium-sized tea tree varieties suitable for making black tea include Jiukeng, Fuding Dabai, Quyeqi, Qimen Chuyezhong, and Huangguanyin;

[0063] (2) Place the fresh leaves picked in step (1) into a continuous withering system for dynamic withering treatment with variable temperature and light control, and wither until the leaf moisture content is 64% to obtain withered leaves, wherein:

[0064] The relative humidity of the environment is controlled at 75%, the thickness of the spread leaves is 6cm, and the compound withering combination of hot wind red light withering and cold wind white light withering is used to alternately treat, which fully promotes the increase of soluble sugar and amino acid content in the leaves. The dynamic operation on the conveyor b...

Embodiment 3

[0082] A processing method for glutinous sweet floral black tea, comprising:

[0083] (1) Picking the fresh leaves of the tea tree species suitable for making black tea as a raw material, wherein:

[0084] The small and medium-sized tea tree varieties suitable for making black tea include Jiukeng, Fuding Dabai, Quyeqi, Qimen Chuyezhong, and Huangguanyin;

[0085] (2) Place the fresh leaves picked in step (1) into a continuous withering system for dynamic withering treatment with variable temperature and light control, and wither until the leaf moisture content is 62% to obtain withered leaves, wherein:

[0086] The relative humidity of the environment is controlled at 70%, the thickness of the spread leaves is 4cm, and the compound withering combination of hot wind red light withering and cold wind white light withering is used to alternately carry out treatment, which fully promotes the increase of soluble sugar and amino acid content in the leaves. The dynamic operation on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com