Graphene copper-containing superconductive heat dissipation device

A heat sink, graphene technology, applied in transportation and packaging, electrochemical generators, electric vehicles, etc., can solve the problems of incapable power battery heat quickly dissipated to the outside, low battery cooling efficiency, low heat transfer coefficient, etc. Achieve excellent thermal conductivity, improve heat dissipation efficiency, and achieve the effect of radiation heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

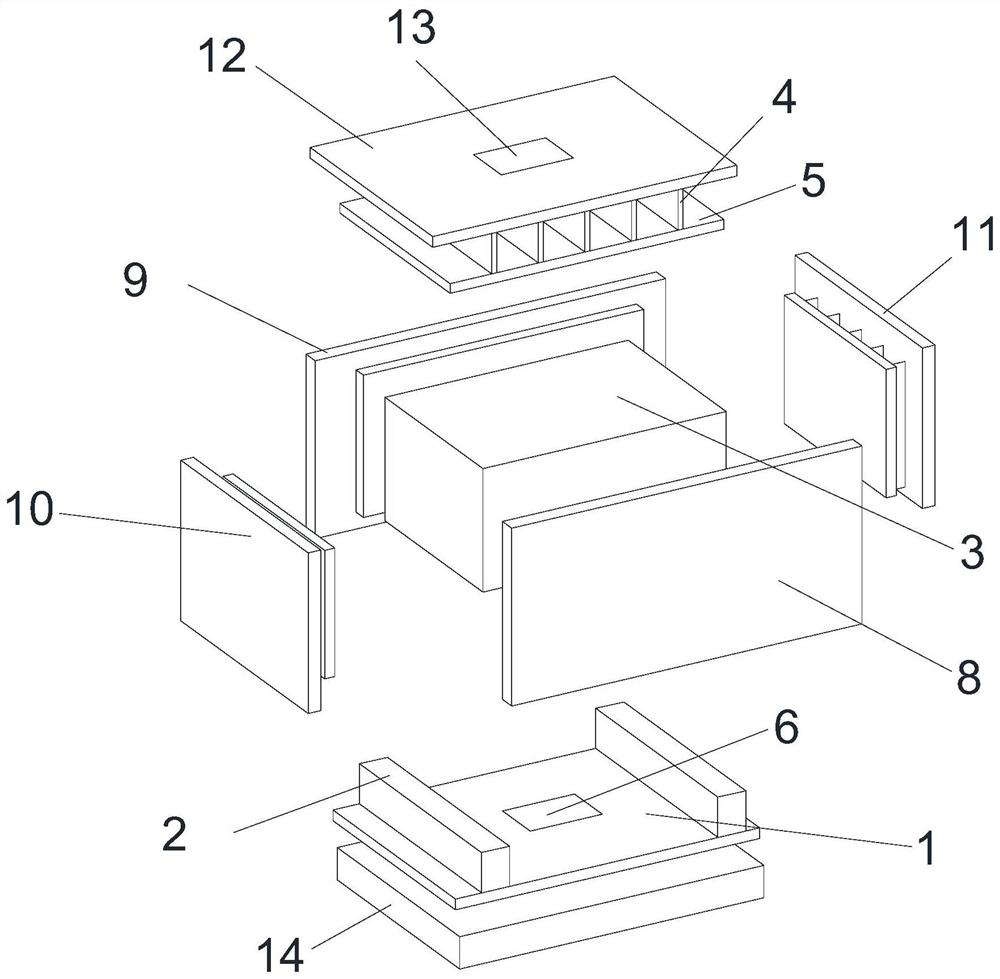

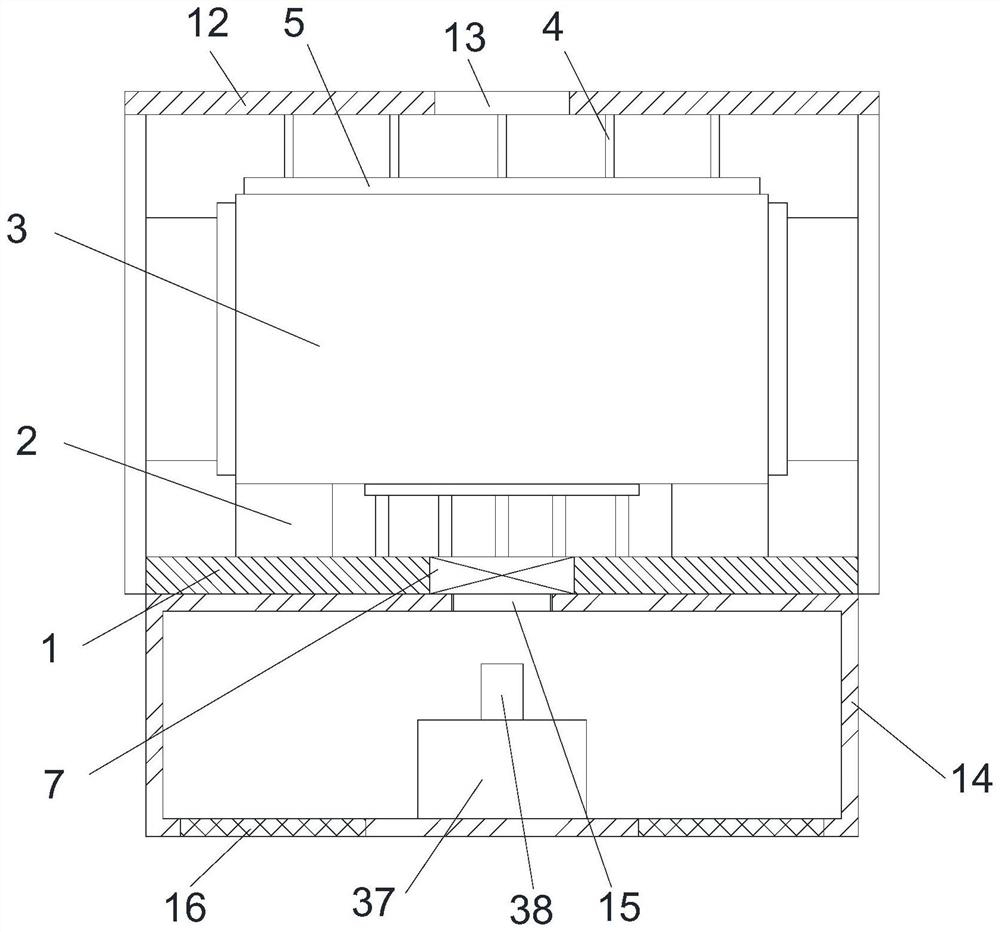

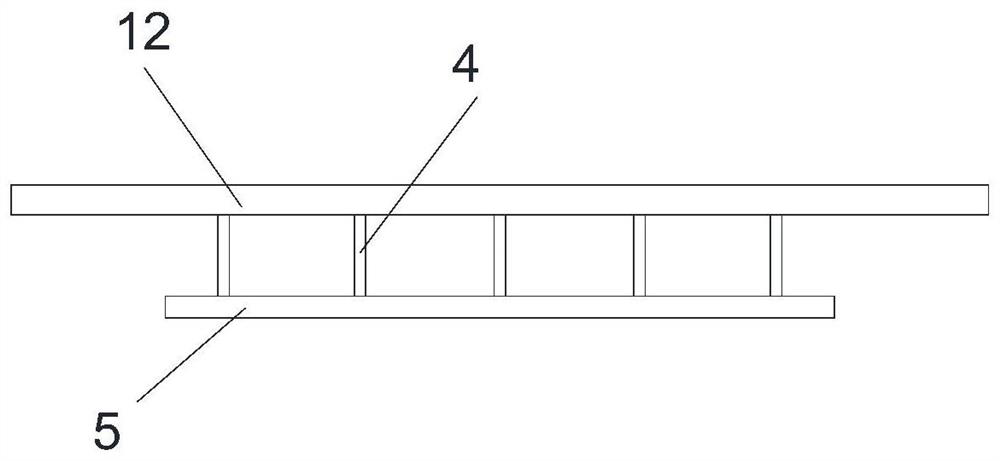

[0052] The embodiment of the present invention provides a superconducting cooling device containing graphene copper, such as Figure 1-5 As shown, it includes: a cooling box, the bottom of the cooling box is provided with a bottom plate 1, the upper surface of the bottom plate 1 is provided with a support block 2, the upper end of the support block 2 is provided with a battery pack assembly 3, and the inner wall of the cooling box is provided with cooling fins 4 A graphene copper layer is arranged on the outside of the heat sink 4, and a heat conduction plate 5 is arranged on the side of the heat sink 4 facing the battery pack assembly 3, and the heat conduction plate 5 faces the side of the battery pack assembly 3 and is connected with the battery The outer wall of the package component 3 is bonded, and the air inlet 6 is arranged in the bottom plate 1. The upper and lower ends of the air inlet 6 respectively penetrate the upper surface and the lower surface of the bottom plat...

Embodiment 2

[0055] On the basis of above-mentioned embodiment 1, as figure 1 As shown, the heat dissipation box also includes a front side plate 8, a rear side plate 9, a left side plate 10, a right side plate 11 and a top plate 12, and the heat dissipation box is composed of the front side plate 8, the rear side plate 9, the left side plate The side plate 10, the right side plate 11, the top plate 12 and the bottom plate 1 are spliced and combined;

[0056] The top plate 12 is provided with an air outlet 13 , and the upper and lower ends of the air outlet 13 respectively penetrate the upper surface and the lower surface of the top plate 12 .

[0057] The working principle and beneficial effects of the above technical solution are as follows: the cooling box is composed of the front side plate 8, the rear side plate 9, the left side plate 10, the right side plate 11, the top plate 12 and the bottom plate 1, and the front side plate 8, The rear side plate 9, the left side plate 10, the ...

Embodiment 3

[0059] On the basis of Embodiment 1, the outer wall of the heat conducting plate 5 is pasted with a graphene copper heat dissipation patch.

[0060] The working principle and beneficial effects of the above-mentioned technical solution are as follows: a graphene copper heat dissipation patch is pasted on the outer wall of the heat conduction plate 5, and the excellent heat conduction ability of the graphene copper can be used to improve the overall heat conduction capacity of the heat conduction plate 5, so that the heat conduction plate 5 can The heat of the battery pack assembly 3 is quickly dissipated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com