Noise prediction method for power assembly

A prediction method and powertrain technology, applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as low efficiency, long cycle, and difficult operation, so as to shorten the adjustment cycle and identify in advance problems, and the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

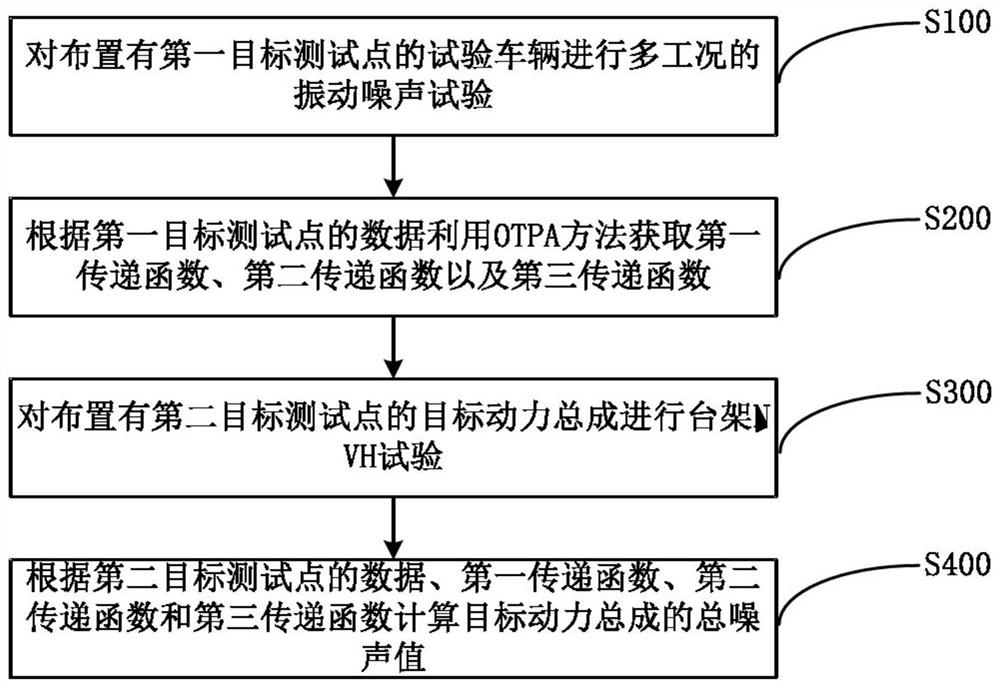

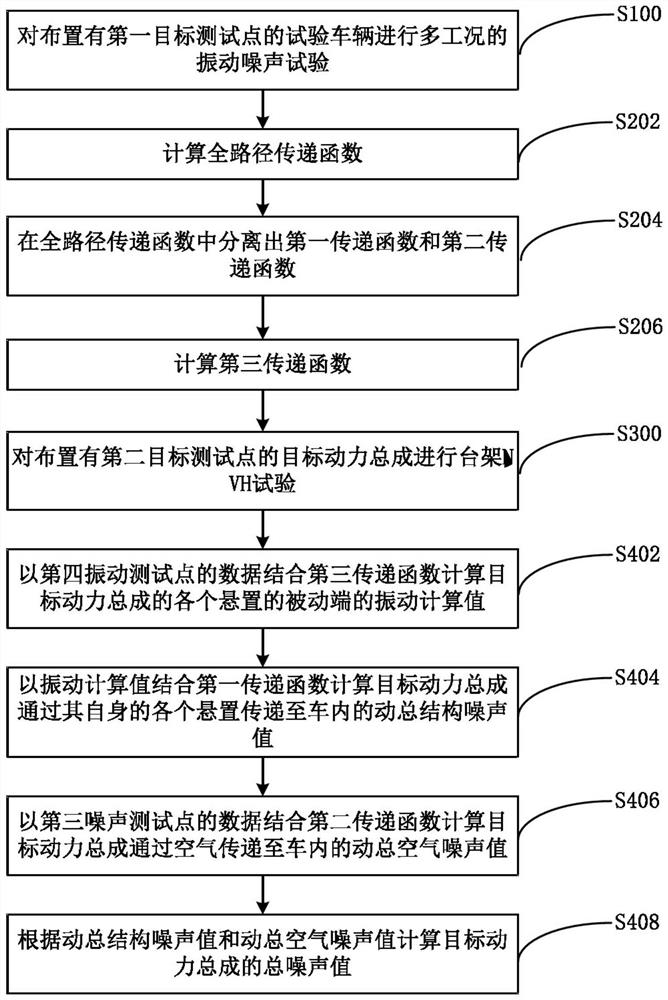

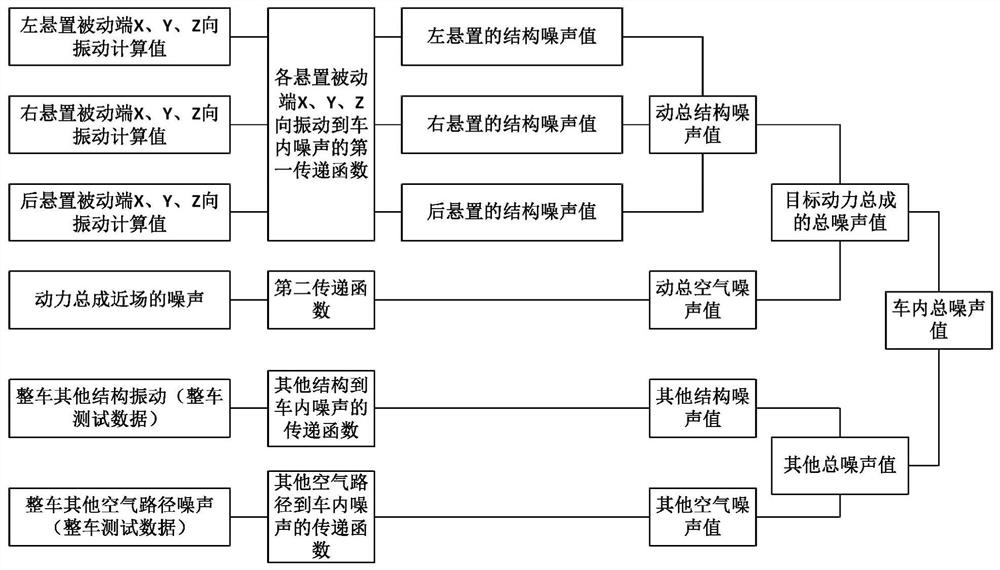

[0053] figure 1 is a flowchart of a powertrain noise prediction method according to an embodiment of the present invention. Such as figure 1 As shown, in one embodiment, the noise prediction method of the powertrain of the present invention comprises:

[0054] In step 100, a multi-condition vibration and noise test is performed on the test vehicle with the first target test point arranged, so as to obtain data of the first target test point. Among them, the test vehicle is a model related to the target powertrain. The model related to the target powertrain here refers to the model that the target powertrain will be equipped with or a similar model, and the powertrain of the test vehicle is the same as the target powertrain. The same or similar type and arrangement. The target powertrain here refers to the powertrain whose noise is to be predicted. The selection of test vehicles should be considered from two levels: from the vehicle level, select the model or similar models...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com