Method for separating and determining lacosamide residual solvent by gas chromatography

A technology of gas chromatography and lacosamide, which is applied in the field of separation and determination of lacosamide residual solvents by gas chromatography, can solve the problems of incomplete removal of residual solvents and affect the safety of medication, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Instruments and Conditions

[0041] Chromatograph: Shimadzu 2010 plus gas chromatograph;

[0042] Detector: hydrogen flame ionization detector;

[0043] Chromatographic column: DB-624UI capillary column (Agilent, 30m´0.32mm, 1.8μm);

[0044] Column temperature: initial temperature 50°C, to 70°C with a rate of increase of 5°C per minute, constant temperature for 5min; to 110°C with a rate of increase of temperature of 5°C per minute, to 180°C, constant temperature for 5 minutes.

[0045] Injection port temperature: 230°C;

[0046] Detector temperature: 260°C;

[0047] Carrier gas (nitrogen) flow rate: 1.0mL / min;

[0048] Split ratio: 20:1;

[0049] Injection volume: 1μL

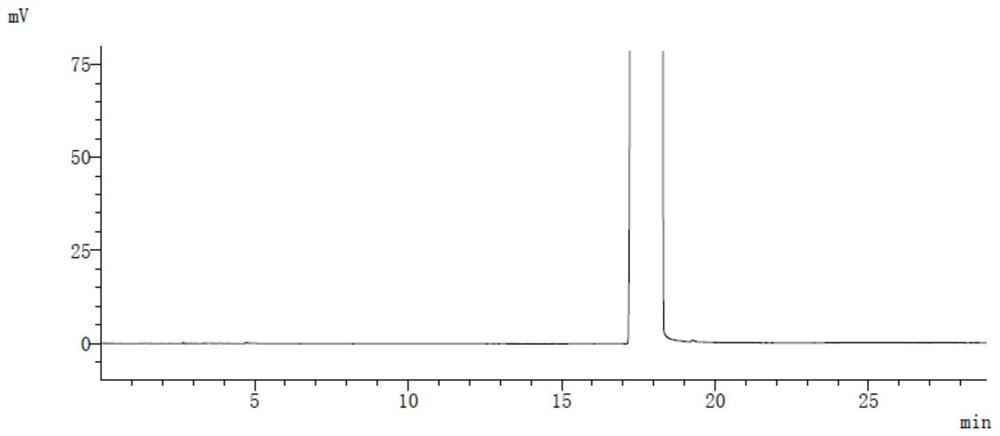

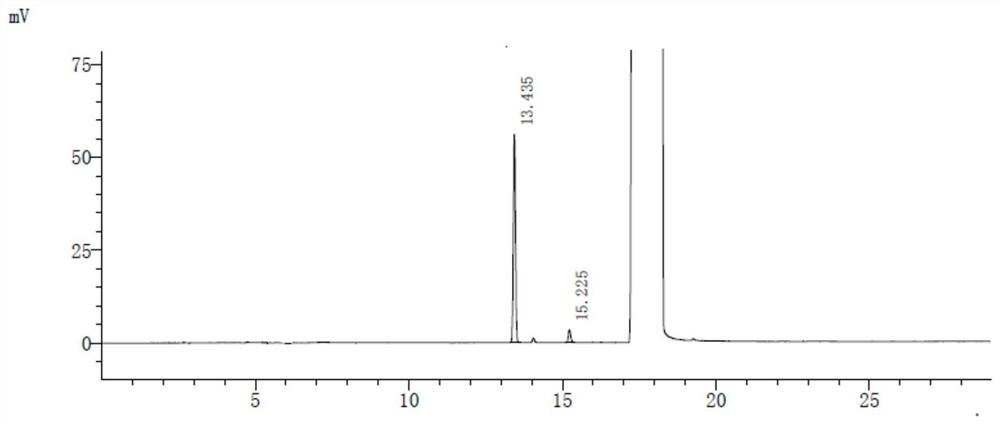

[0050] Experimental procedure

[0051] Take 100mg~200mg of lacosamide, dissolve it with a solvent, and prepare a test solution containing 100~200mg of lacosamide per 1mL; take an appropriate amount of each residual solvent, dissolve it with a solvent, and prepare a solution containing methyl Is...

Embodiment 2

[0053] Instruments and Conditions

[0054] Chromatograph: Shimadzu 2010 plus gas chromatograph;

[0055] Detector: hydrogen flame ionization detector;

[0056] Chromatographic column: DB-624UI capillary column (Agilent, 30m´0.32mm, 1.8μm);

[0057] Column temperature: initial temperature 50°C, to 70°C with a rate of increase of 5°C per minute, constant temperature for 5min; to 110°C with a rate of increase of temperature of 5°C per minute, to 200 ° C, constant temperature 5min.

[0058] Injection port temperature: 230°C;

[0059] Detector temperature: 260°C;

[0060] Carrier gas (nitrogen) flow rate: 1.0mL / min;

[0061] Split ratio: 20:1;

[0062] Injection volume: 1μL

[0063] Experimental procedure

[0064] Take an appropriate amount of each residual solvent, dissolve it with a solvent, and prepare a reference solution containing 500 μg-1000 μg of methyl isobutyl ketone and 495 μg-990 μg of N-methylmorpholine per 1 mL, take 100 mg-200 mg of lacosamide, add Shake 1.0 m...

Embodiment 3

[0066] Instruments and Conditions

[0067] Chromatograph: Shimadzu 2010 plus gas chromatograph;

[0068] Detector: hydrogen flame ionization detector;

[0069] Chromatographic column: DB-624UI capillary column (Agilent, 30m´0.32mm, 1.8μm);

[0070] Column temperature: initial temperature 50°C, to 110°C at a heating rate of 5°C per minute, constant temperature for 3min; to 200°C at a heating rate of 10°C per minute, constant temperature for 5min.

[0071] Injection port temperature: 230°C;

[0072] Detector temperature: 260°C;

[0073] Carrier gas (nitrogen) flow rate: 1.0mL / min;

[0074] Split ratio: 20:1;

[0075] Injection volume: 1μL

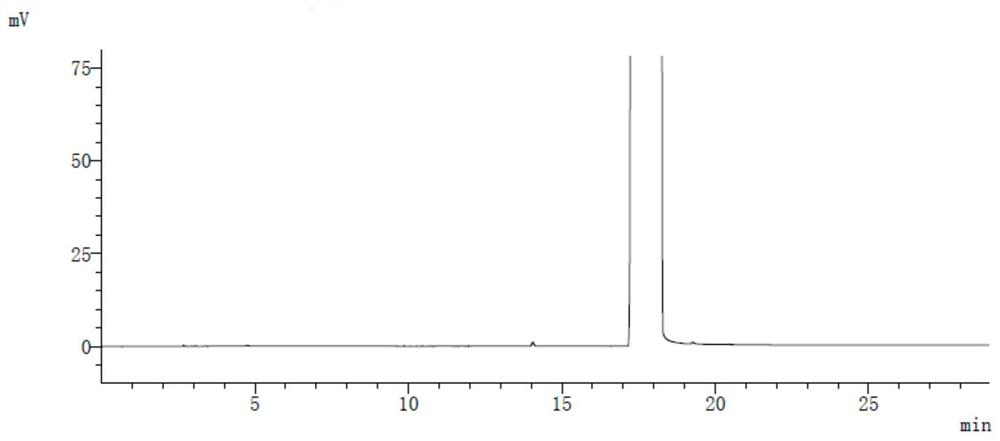

[0076] Experimental procedure

[0077] Take an appropriate amount of each residual solvent, dissolve it with a solvent, and prepare a reference solution containing 500μg-1000μg of methyl isobutyl ketone and 495μg-990μg of N-methylmorpholine per 1mL; take another 100mg~200mg of lacosamide, Add 1.0 mL of reference substance solution, sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com