Multi-gear hub transmission with three motors and two brakes

A hub transmission and brake technology, which is applied to vehicle gearboxes, transmission components, mechanical equipment, etc., can solve the problems of single-speed shifting, high energy consumption and difficulty in motor transmissions, and achieves low shifting impact, compact structure, Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

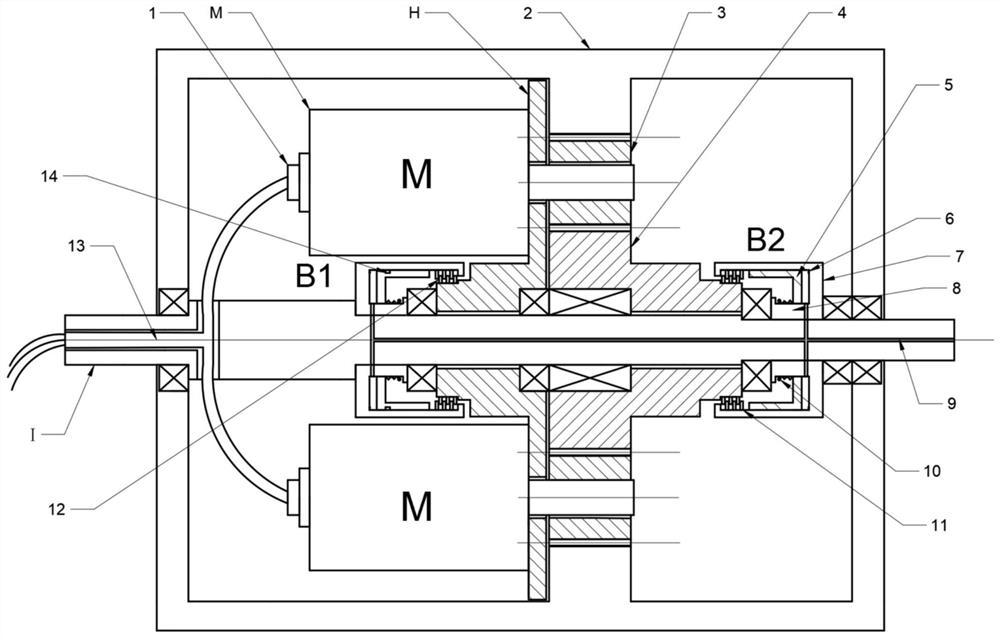

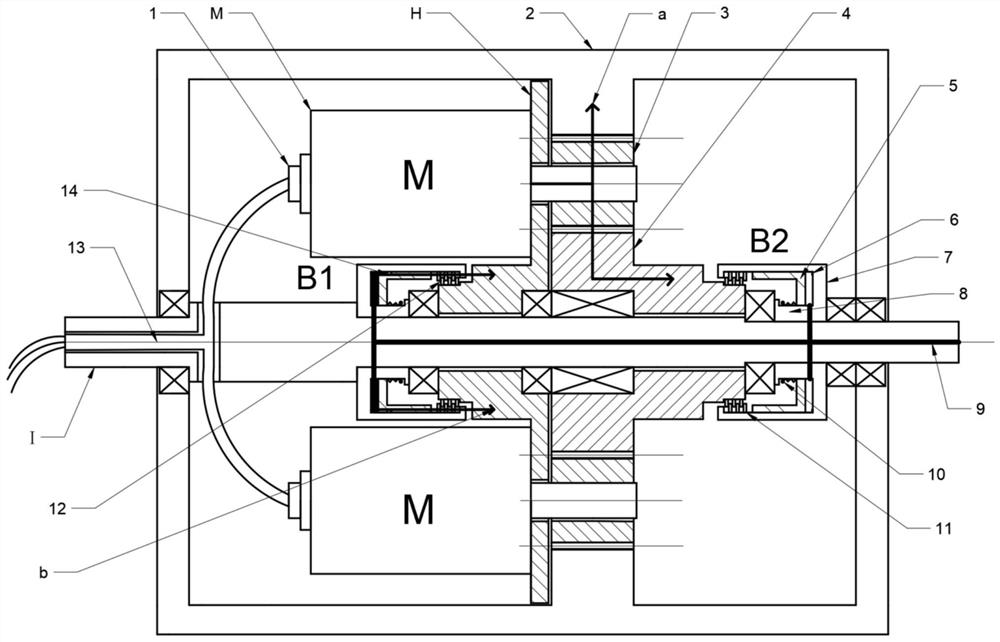

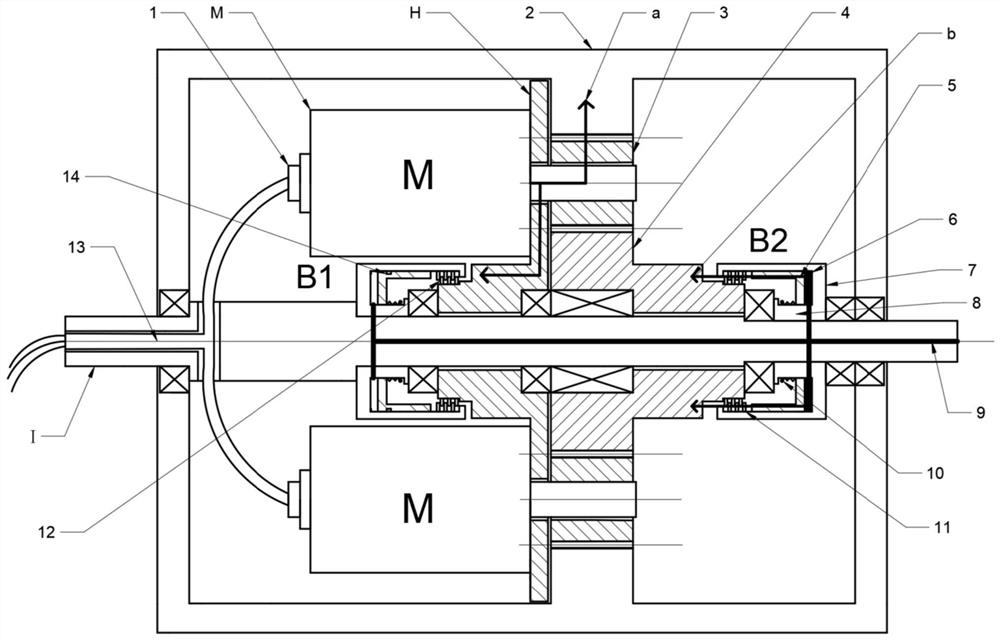

[0022] like figure 1 As shown, the present invention relates to a three-power two-speed variable speed hub motor device, which is mainly composed of a motor M, a first brake B1, a second brake B2, a planetary gear train, a rotor 2, and a stator I.

[0023] The shell of the motor M is connected to the planetary carrier H, the rotating shaft of the motor M is connected to the planetary wheel 3 through a key, the electric wire of the motor M passes through the electric slip ring 1 and then enters the wire hole 13 of the stator Ⅰ to pass through the hub motor, and the motor M is installed inside. In the planetary gear system, the center wheel 4 is externally meshed with the planetary wheel 3, and the planetary wheel 3 is internally meshed with the rotor 2. At the same time, the stator I shaft is provided with two shoulders, oil passage 9, and wire hole 13; the center wheel 4 and the stator I Bearings are installed between them; bearings are installed between planet carrier H and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com