Octahedral end plate assembly, structural unit and assembling structure thereof

A technology of structural unit and eight-sided end plate, which is applied in the direction of building construction and construction, and can solve the problems of increasing processing costs, inconvenient processing of beam units and column units, and inconvenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

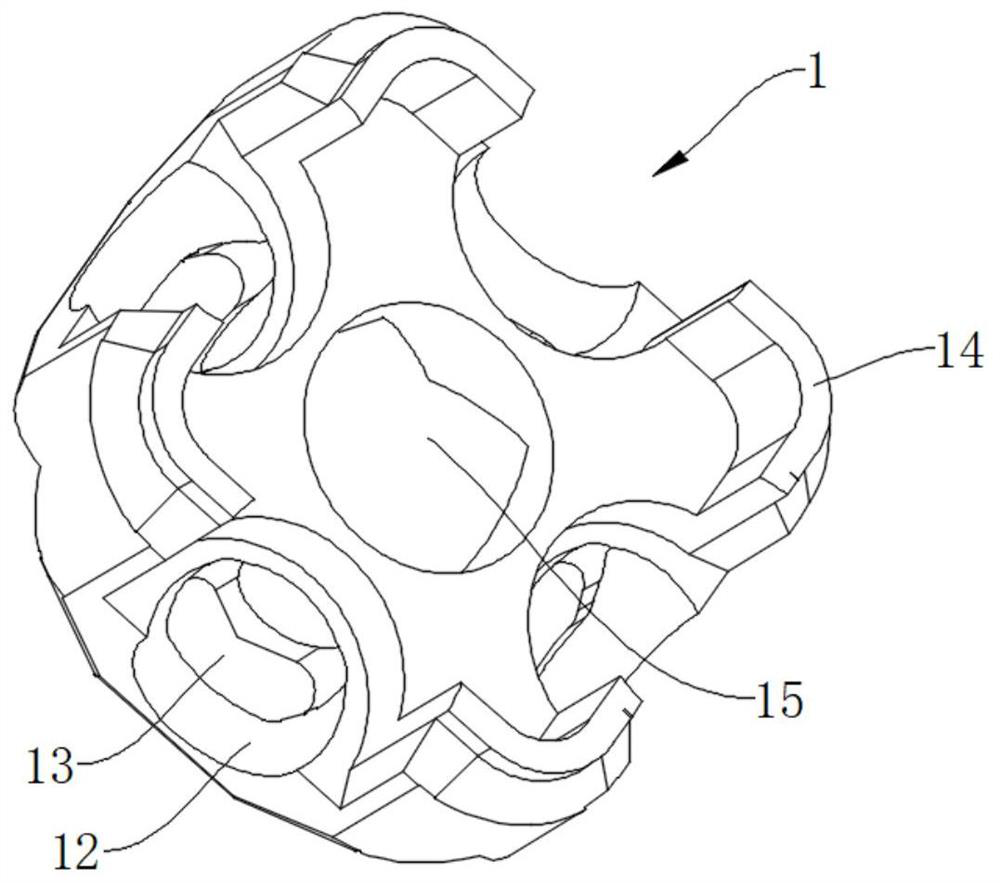

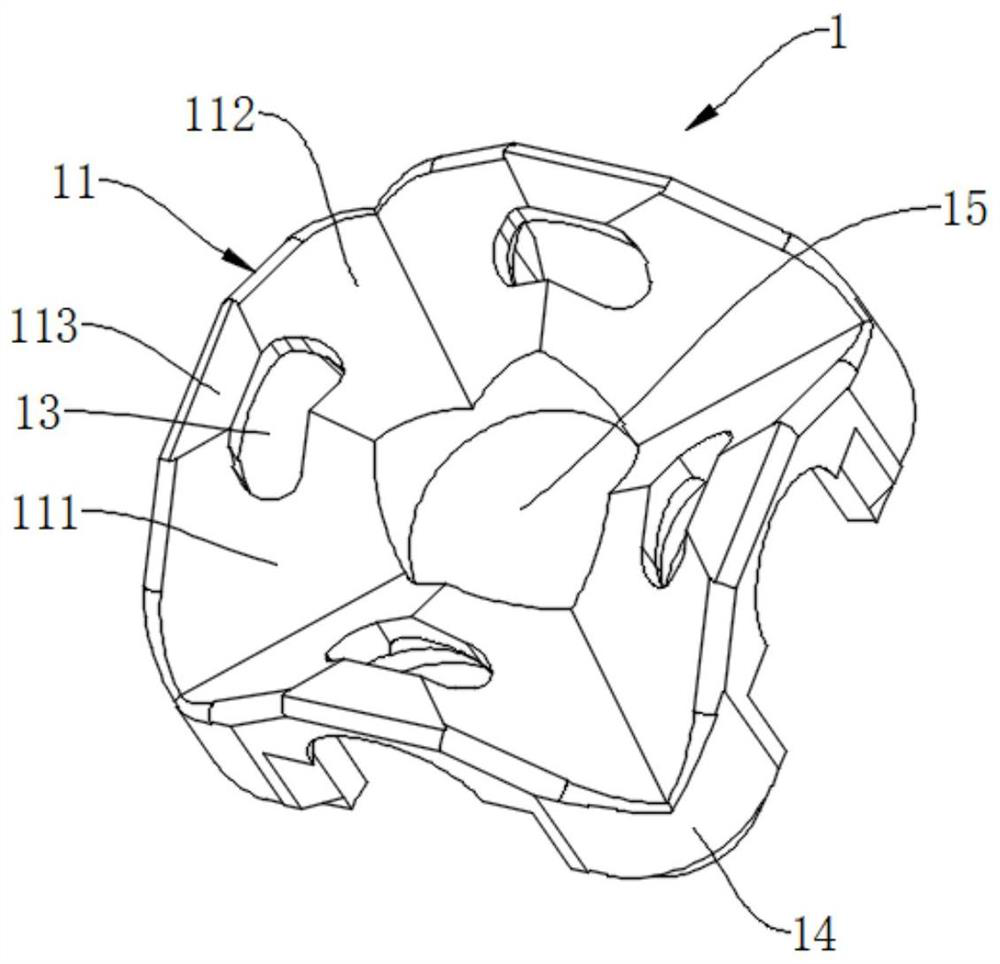

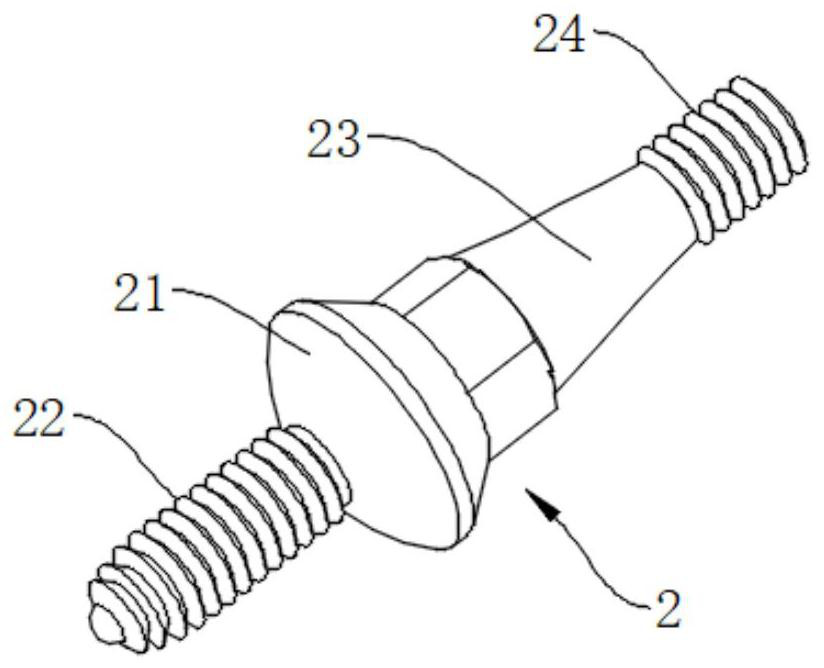

[0037] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment provides an eight-sided end plate assembly, including an eight-sided end plate 1, refer to figure 1 and figure 2 , the eight-sided end plate 1 includes a square body, one side of the body is provided with four centrally symmetrically arranged protrusions 11, and the side of the protrusions 11 away from the body has a first slope 111 and a second slope 112, the top of the first slope 111 and the top of the second slope 112 of the same protrusion 11 intersect, between two adjacent protrusions 11, the bottom of the first slope 111 of one protrusion 11 and the other The bottoms of the second slope 112 of one protruding portion 11 intersect in the diagonal direction of the body, so that two locking grooves are respectively formed in the two diagonal directions of the body. A center hole 15 is formed through the middle of the body, and the center hole 15 passes through the first in...

Embodiment 2

[0045] like Image 6 , Figure 7 and Figure 8 As shown, a structural unit provided by the present invention includes the above-mentioned eight-sided end plate assembly, and also includes a square steel pipe 5, the four edges of the square steel pipe 5 are rounded, and the eight-sided end plate 1 is fixedly embedded in the The inner circumference of the end of the square steel pipe 5, specifically, the four connecting parts 14 of the eight-sided end plate 1 are respectively welded to the four corners of the square steel pipe 5; the four side walls of the square steel pipe 5 are equidistant along its length direction A plurality of connection holes 51 capable of screwing with the first threaded portion 22 are provided.

[0046] In this embodiment, the square steel pipe 5 can be used as a beam or as a column. When splicing, the corner joint or butt joint of the square steel pipe is realized by using the eight-sided end plate assembly.

[0047] When cornering, refer to Image...

Embodiment 3

[0051] An assembled structure of structural units provided in this embodiment includes a parallel beam unit formed by assembling the structural units provided in Embodiment 2, and the distance between two adjacent mutually parallel structural units in the parallel beam unit is na, in this embodiment, the distance is specifically 450mm, to form a criss-cross beam structure ( Figure 12 ).

[0052] This embodiment also provides a parallel column unit formed by assembling several structural units, the distance between two adjacent structural units in the parallel column unit is na, and the distance is specifically 450mm, to form an L-shaped column ( Figure 9 ), T-pillar ( Figure 10 ) and cross-shaped columns ( Figure 11 ).

[0053] This embodiment also provides a docking column unit formed by assembling several structural units. The distance between two adjacent structural units in the docking column unit is 0.25 na, and the distance is specifically 112.5 mm. Refer to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com