Structure for segmenting and sectioning steel plate wall under influence of trusses of intelligent jacking steel platform

A steel plate wall and steel platform technology, which is applied in the field of the steel plate wall segmented structure under the influence of the intelligent jacking steel platform truss, can solve the problems affecting the cross construction progress and efficiency, the steel plate wall hoisting construction efficiency is slow, the steel plate wall has a great influence, etc. problems, to achieve good development prospects, efficient and safe construction, cost-reduction and efficiency-increasing construction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

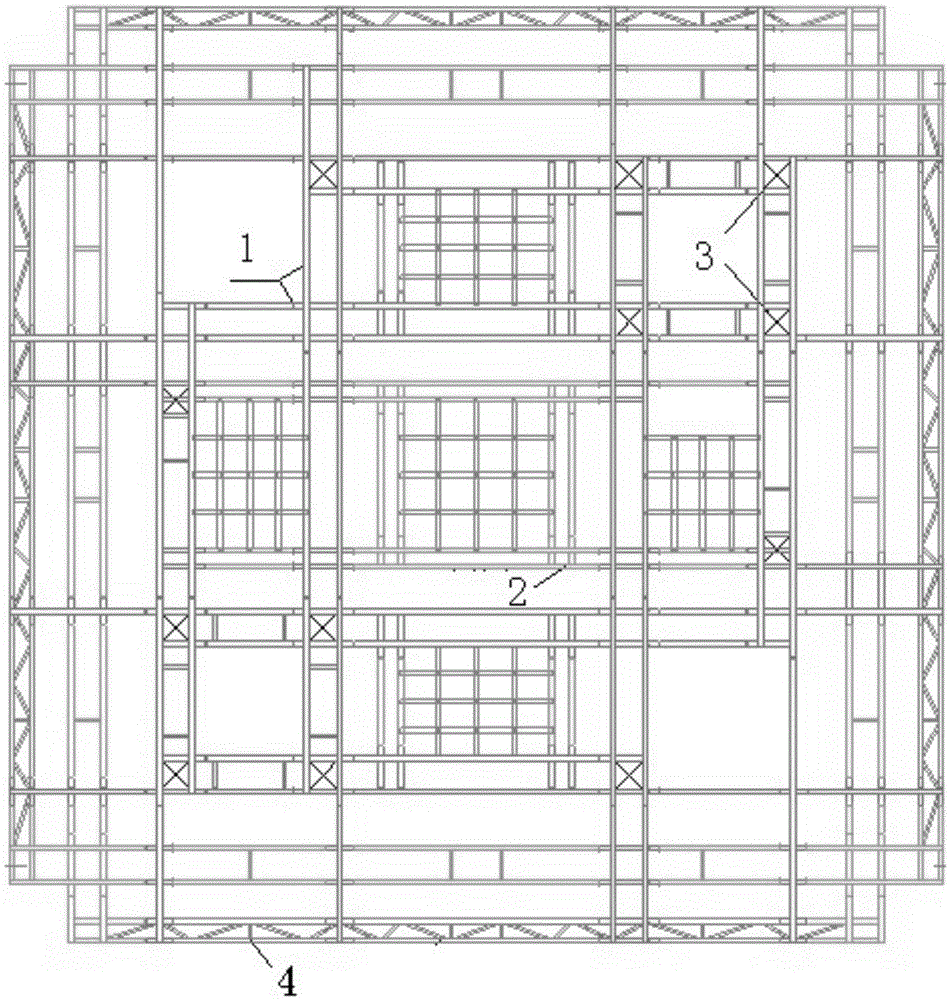

[0017] The segmented and segmented structure of the steel plate wall under the influence of the intelligent jacking steel platform truss of the present invention, its preferred specific implementation mode is:

[0018] The steel plate wall of the core tube is segmented in the elevation direction according to the following structure, and each segment is segmented in the plane direction:

[0019] The height of each section of the steel plate wall is the same as the standard height of the top form;

[0020] When each section of the steel plate wall is segmented, the part of the structure under greater stress is staggered, and the longitudinal welds are staggered, and the length of the segment makes the distance between the position of the steel concealed beam and the weld greater than 400mm.

[0021] The weight of each steel plate wall is less than or equal to 23.2 tons.

[0022] The steel plate wall is divided into sections according to one floor, and the height is 4.5m.

[00...

specific Embodiment

[0026] Segmentation and section considerations:

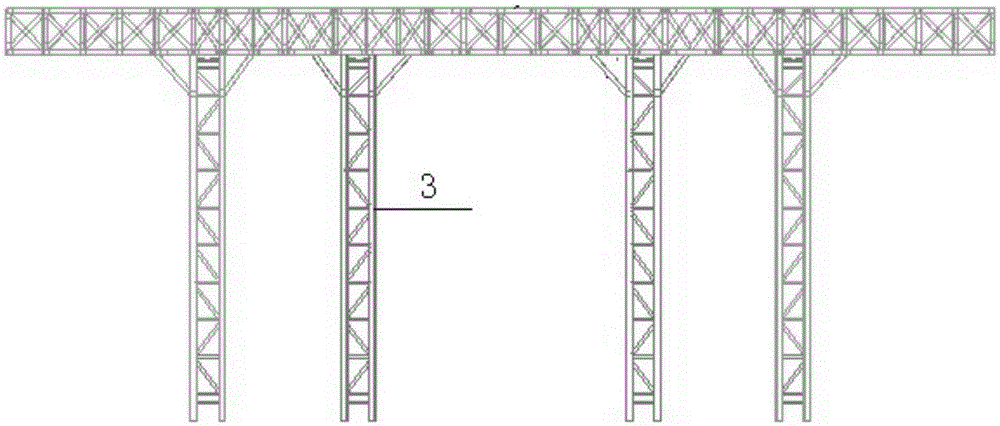

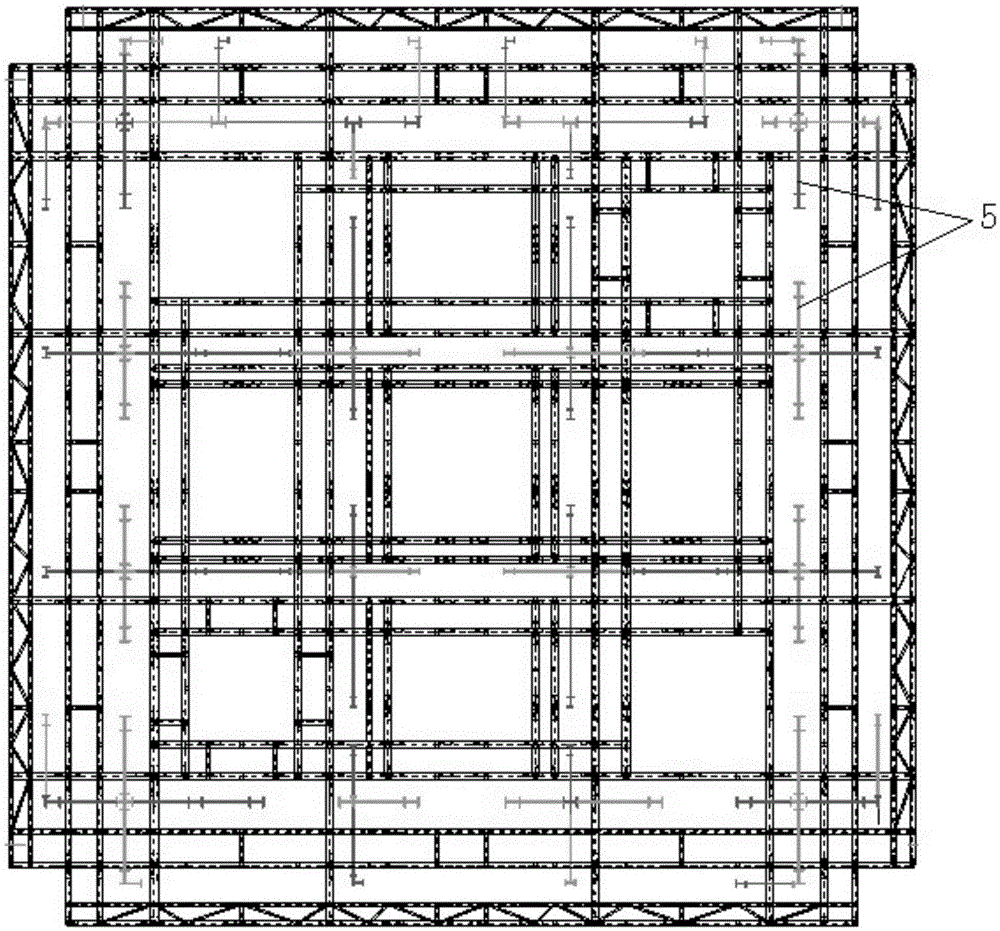

[0027] (1) When the steel members of the core tube are segmented, the parts of the structure under greater stress should be staggered, and the longitudinal welds should be staggered as far as possible. After segmenting and segmenting, the unit components should have overall stability to prevent excessive deformation during transportation and hoisting. Comprehensively considering the impact of steel plate wall segmentation and section, intelligent jacking steel platform truss, electromechanical and various specialties, a reasonable segmentation scheme is formulated to facilitate installation.

[0028] (2) The segment length and width meet the transportation conditions, which are convenient for on-site measurement and the size restrictions caused by the primary and secondary trusses of the intelligent jacking steel platform. Considering that the step distance between the top formwork system and the steel plate wall construction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com