Graphene thermal interface material production device and preparation method thereof

A technology of thermal interface materials and production equipment, applied in the direction of graphene, heat exchange materials, chemical instruments and methods, etc., to achieve low price, excellent thermal conductivity, and improve the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

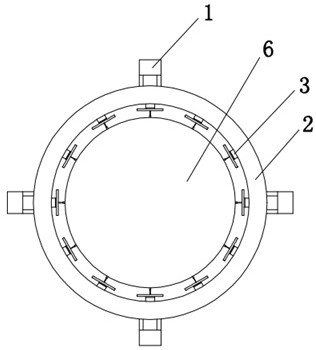

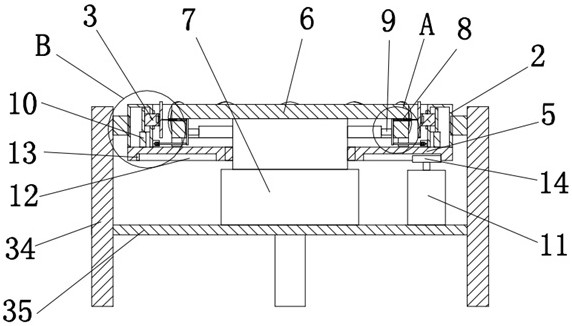

[0041] see Figure 1-7 , a graphene thermal interface material production device, comprising a fixed frame 1, the upper end of the fixed frame 1 is provided with a transmission box 2, the inner wall of the transmission box 2 is provided with a rotation fixing seat 3, and the rotation fixing seat 3 is provided with a plurality of ring arrays, The center of the transmission box 2 is concentrically provided with a microneedle cutting seat 6, and the lower end of the fixed frame 1 is provided with a drive mechanism 4, the drive mechanism 4 includes an indexing turntable 7 and a synchronous deflection motor 11, and the upper end of the output turntable of the indexing turntable 7 is connected to the microneedle cutting machine. The seat 6 is fixedly connected, and the middle part of the output turntable is rotated with a synchronous chassis 5, the synchronous chassis 5 and the rotation fixed seat 3 are connected through a synchronous deflection transmission mechanism 10, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com