Paper pulp mud for manual molding and manual molding method

A kind of pulp and manual technology, applied in the direction of coating, etc., can solve the problems that cannot meet the requirements of manual mold molding, pulp mud sticks to the mold wall, and the finished pulp mud is not firm enough, so as to exercise hands-on ability and three-dimensional space imagination ability , good plasticity, and the effect of enhancing cognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A paper pulp slurry for manual molding is made of the following components in terms of weight percentage, 44% paper pulp, 18% corn starch, 21.4% manual paste, 14% cooked gypsum powder and 2.6% edible oil.

[0028] The preparation method comprises the following steps:

[0029] (1) Pulp manufacturing: shred waste paper (waste paper includes: printing paper, newspaper, handmade paper, rice paper, etc.) Paper; Pour all the materials in the container into the mixer, and then pour them into the sieve basin after mixing; finally press the pulp with your hands to make the water in the pulp flow out of the sieve basin, and the approximate dehydration amount is 80% to 85%. That's it.

[0030] (2) Material mixing and stirring: mix paper pulp, corn starch, and manual paste in proportion and then fully stir, so that paper fibers, starch, and paste can be more compact, and the fiber network can be firmer; then add cooked gypsum powder and stir, cooked gypsum After the powder is add...

Embodiment 2

[0035] A paper pulp slurry for manual molding is made of the following components in terms of weight percentage: 41% paper pulp, 20.6% corn starch, 21.2% manual paste, 14% cooked gypsum powder and 3.2% edible oil.

[0036] The preparation method is the same as in Example 1.

[0037] After the pulp mud material is manually molded, a block with a diameter of about 3 cm is obtained. After 48 hours of drying in the air at room temperature at 20-30°C, apply water-based paint on the surface and let it stand for about 5 minutes. The final molded product has a very smooth appearance, fast demoulding speed, fine surface, light weight, and is not easy to break or be affected by moisture.

Embodiment 3

[0039] A paper pulp slurry for manual molding is made of the following components in terms of weight percentage, 41% paper pulp, 18.8% corn starch, 22% hand paste, 16% cooked gypsum powder and 2.2% edible oil.

[0040] The preparation method is the same as in Example 1.

[0041] After the pulp mud material is manually molded, a block with a diameter of about 3 cm is obtained. After 48 hours of drying in the air at room temperature at 20-30°C, apply water-based paint on the surface and let it stand for about 5 minutes. The final molded product has a relatively full appearance, a high degree of molding reduction, small voids, strong toughness, clear surface texture, light weight, and is not easy to break or be affected by moisture.

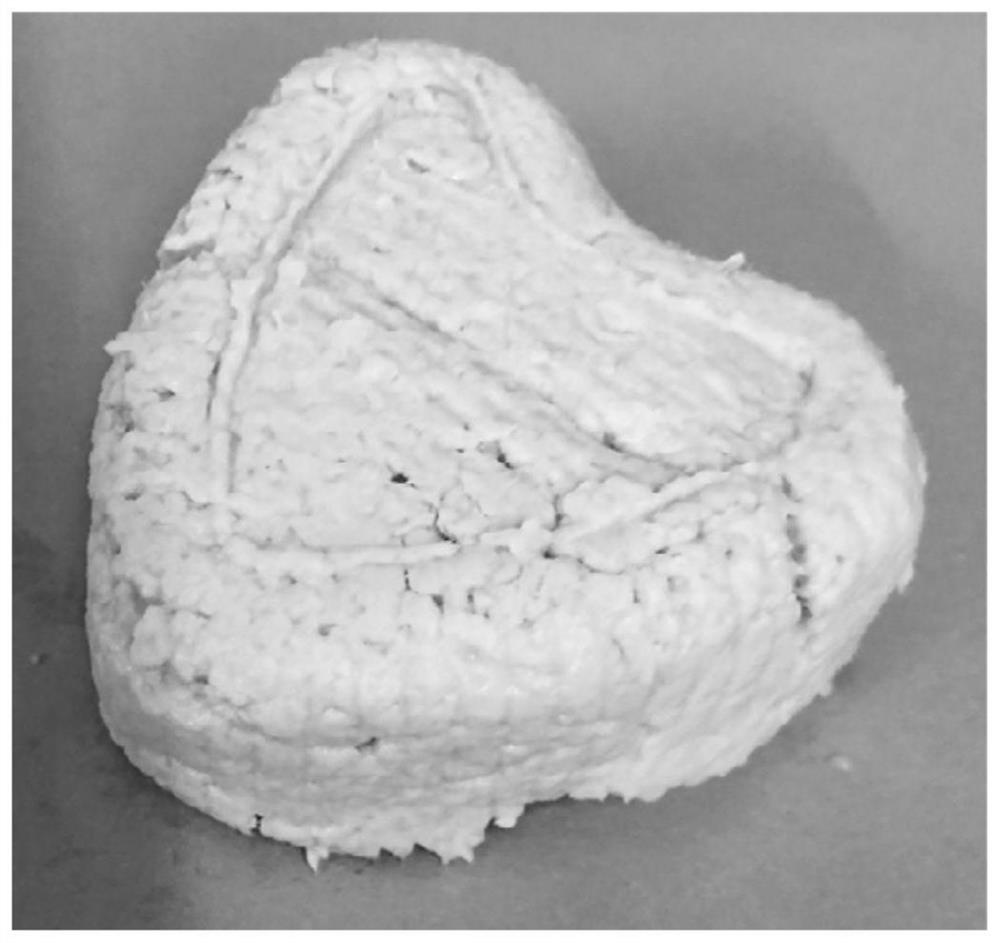

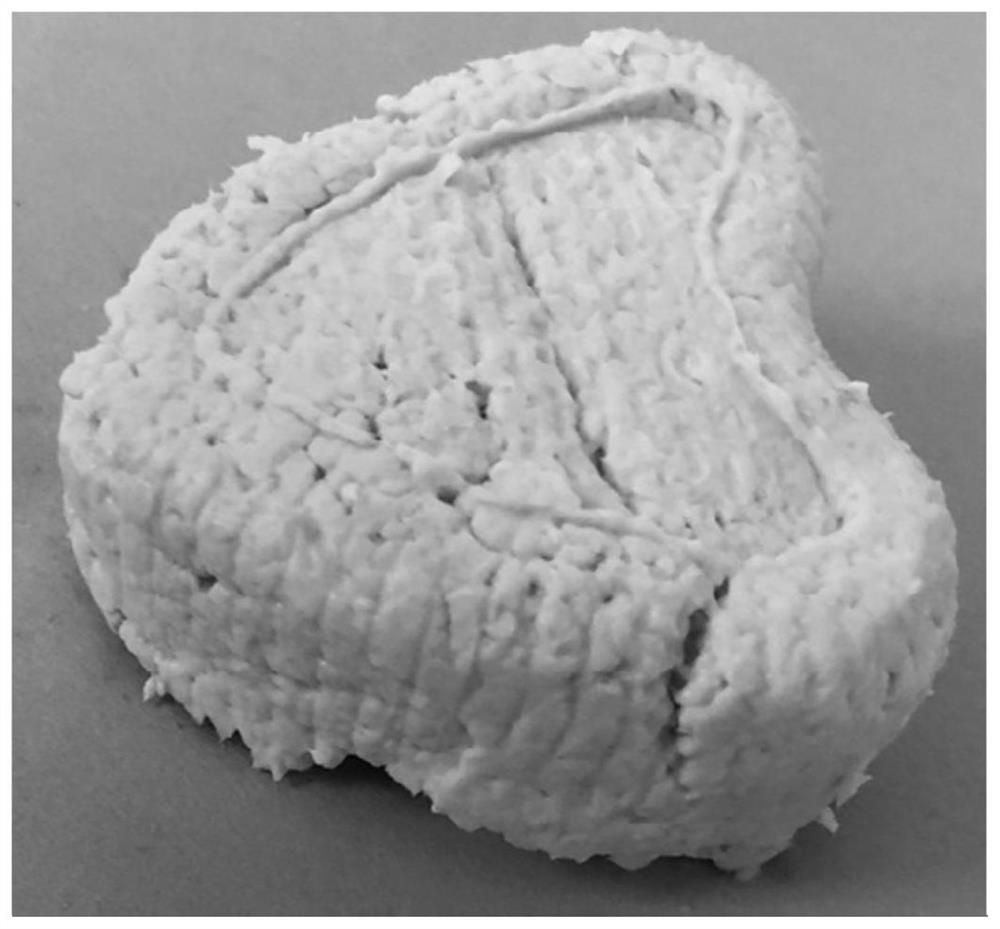

[0042] Such as figure 1 , figure 2 As shown, the finished pulp mud product without adding cooked gypsum powder: the molded product is obviously soft and slumped, and the shaping effect is poor.

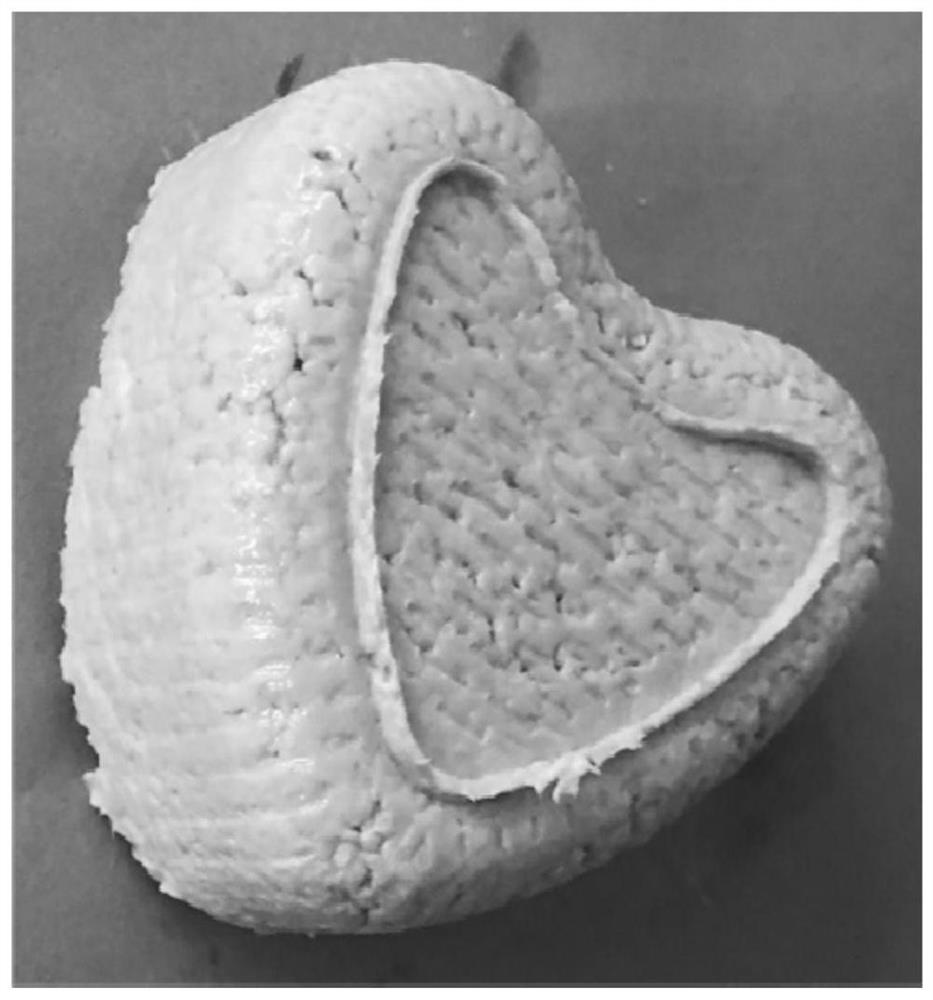

[0043] Such as image 3 , Figure 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com