Production line for disposable edge-rolling paper cups

A one-time, production line technology, applied in the manufacture of paper, paper/cardboard containers, rigid/semi-rigid containers, etc., can solve the problems of low production efficiency, difficult to decompose plastic structure, large production consumables, etc., and achieve full and smooth roll mouth Beautiful, neat and orderly folding edge of the cup body, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

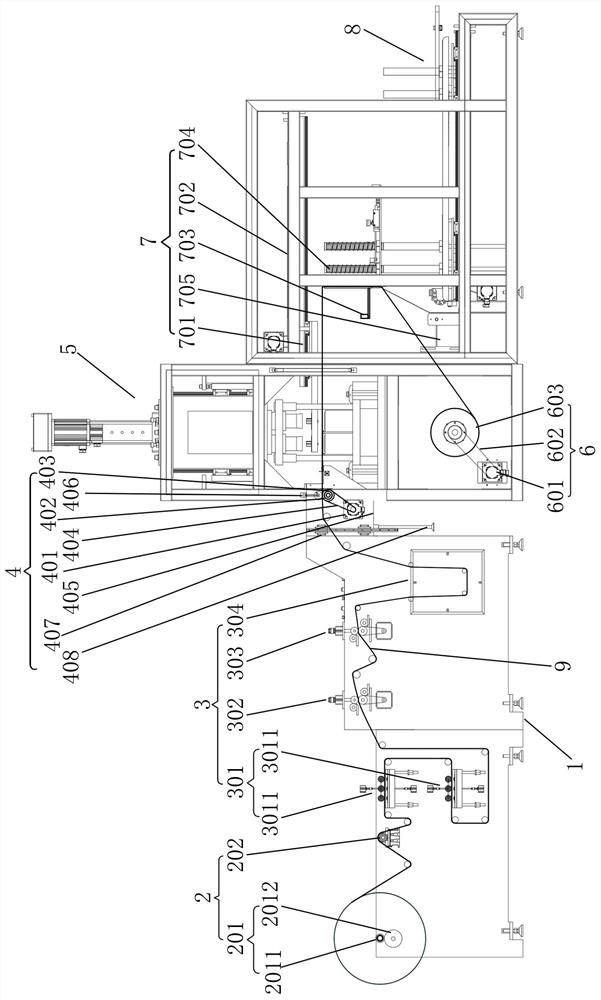

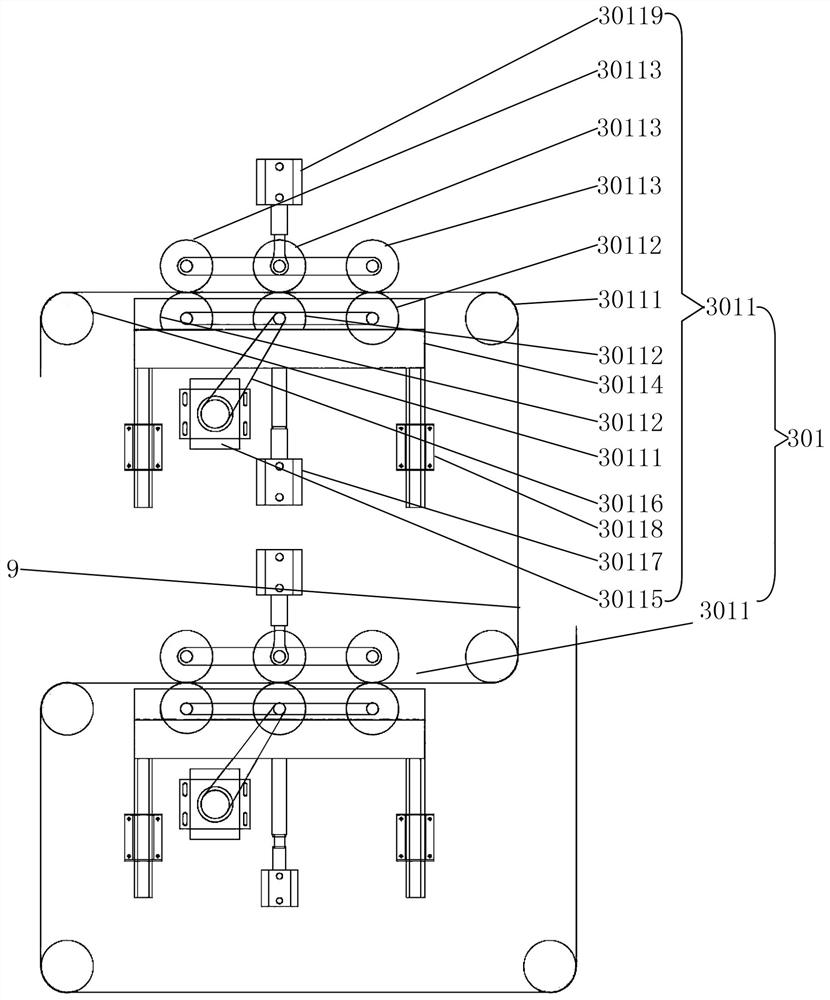

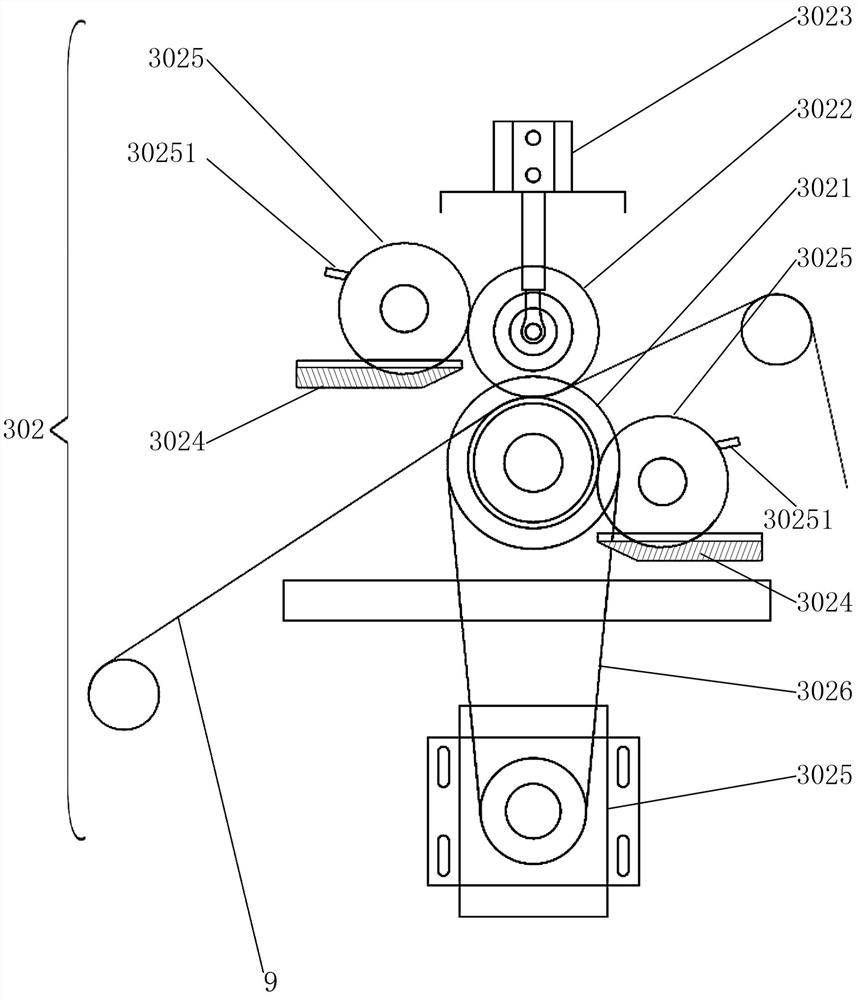

[0022] Such as Figure 1-6 As shown, the disposable roll-top paper cup production line in this preferred embodiment includes a frame 1 and a rack that is respectively installed on the frame 1 and distributed sequentially from left to right along the longitudinal direction of the frame 1 according to the movement order of the paper materials 9. Roll storage mechanism 2, paper surface treatment mechanism 3, adjustable feeding traction mechanism 4, die forming mechanism 5, side material winding mechanism 6, mechanical arm picking mechanism 7, bagging and packaging workbench 8. The paper material 9 is the continuous long strip of paper output by the paper roll.

[0023] The unwinding storage mechanism 2 includes an unwinding unit 201 and a constant tension control device 202; the unwinding unit 201 includes an air shaft guide roller 2011 and an unwinding servo motor 2012; the air shaft guide roller 2011 is rotatably installed On the frame 1 , the unwinding servo motor 2012 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com