Coating roller coating equipment

A coating roller and equipment technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of inability to achieve, poor quality of roller coating, single function, etc., to achieve the effect of realizing intelligence and improving production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention is further described below with reference to the accompanying drawings and examples.

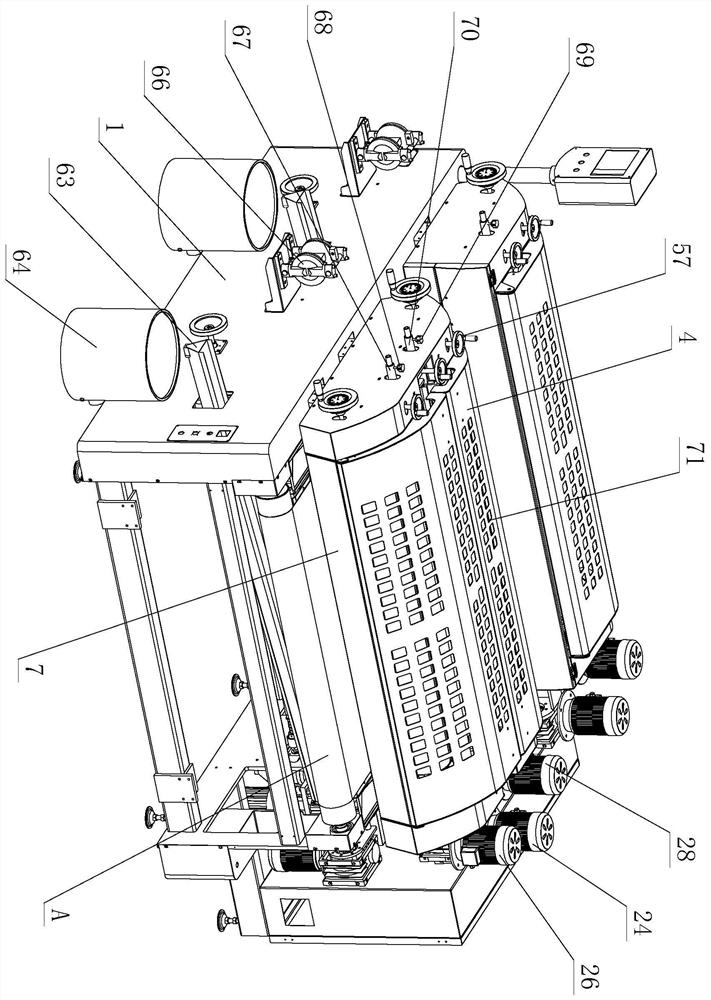

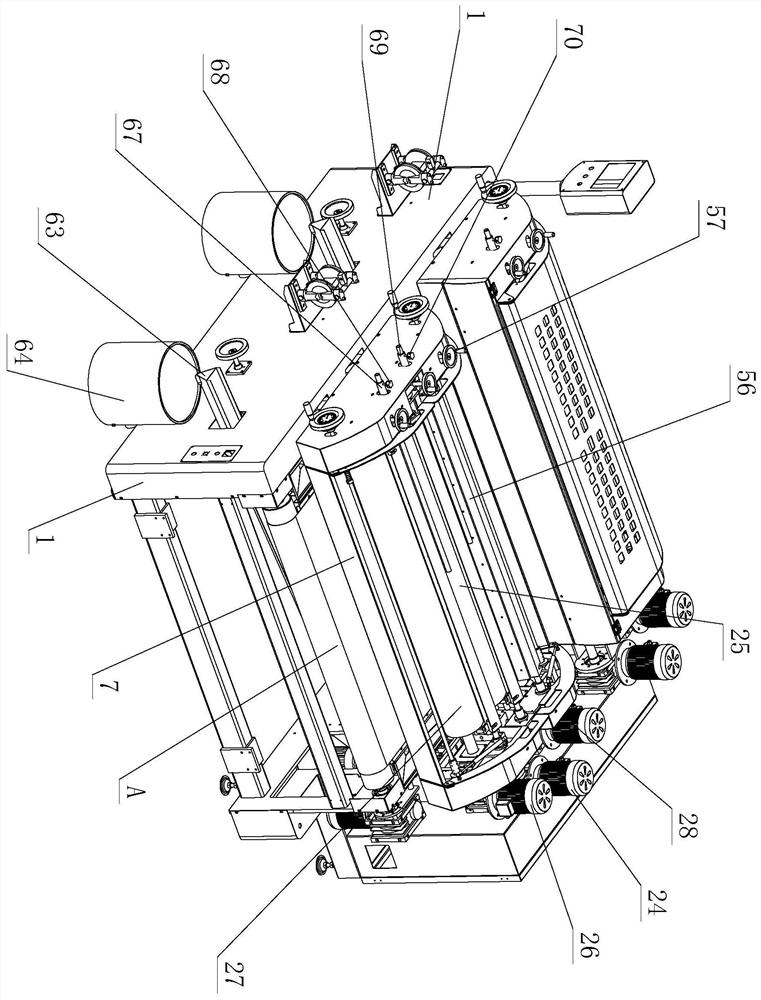

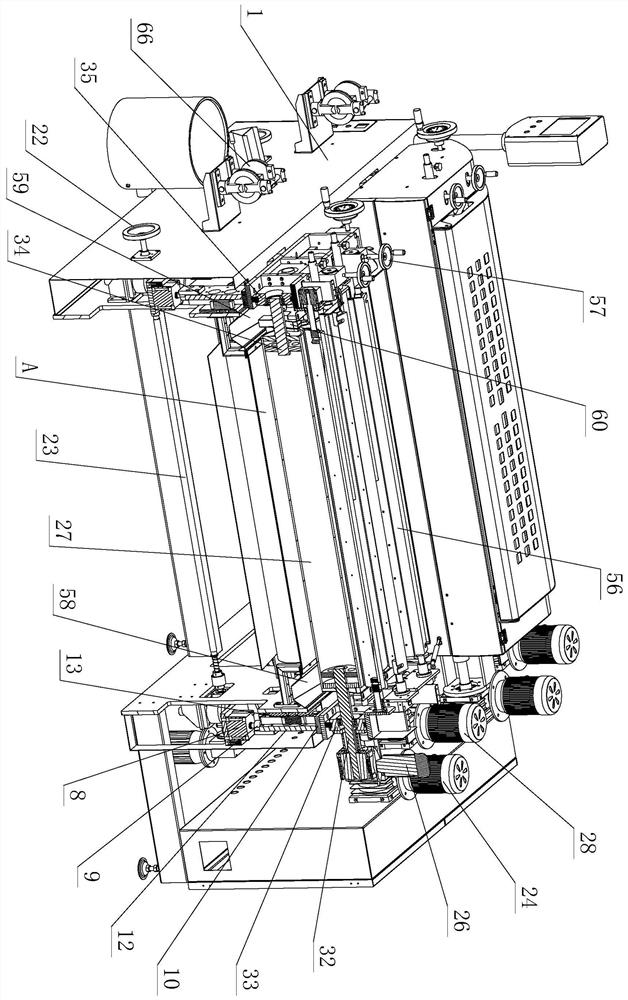

[0068] See Figure 1 - Figure 19 This coating roll coating apparatus includes a roller painting mechanism on the main frame 1, and the main frame 1.

[0069] The roller paint mechanism includes a paint roller device, and a first auxiliary roller device disposed on the side portion of the paint roll device, a second auxiliary roller device; wherein the first auxiliary roller device and the second auxiliary roller device are respectively Turn in different directions on both sides of the paint roll device, and at the time of rotation, it is close to the side of the paint roller device; the paint roller device is based on the first auxiliary roller device, the steering of the second auxiliary roller device In contrast direction.

[0070] The paint roller apparatus is provided with a first auxiliary roller device, and a second auxiliary roller device, respectively, a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com