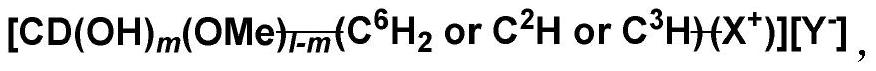

Polyether functionalized cyclodextrin-based biomass organic catalyst and preparation method thereof

An organic catalyst and cyclodextrin technology are applied in the field of cyclodextrin-based biomass organic catalysts and their preparation, and can solve the problems of ineffective utilization of molecules, low effective utilization rate, and destruction of the formation of hydrogen bond networks in CD crystalline regions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

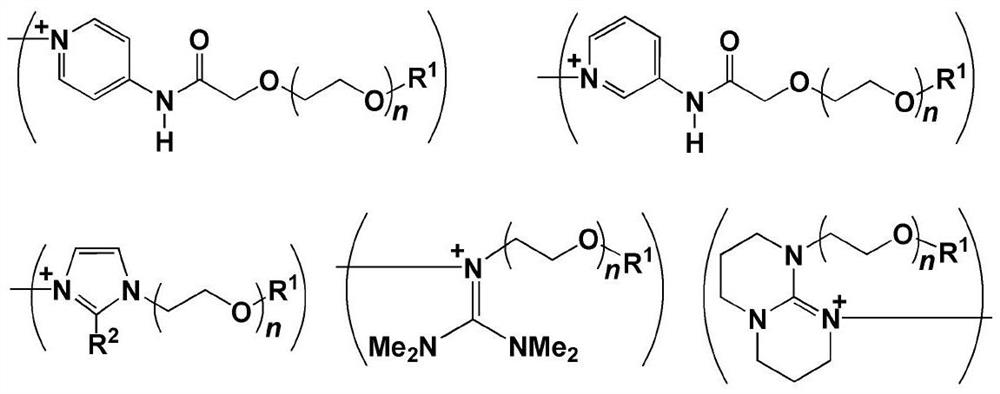

[0053] Catalyst [R 1 (EO) n IMR 2 -C 6 h 2 CD(OH) l ][Y] synthesis (R 1 =CH 3 , R 2 =H, n=16, l=20, Y=1 - )

[0054] The β-cyclodextrin derivative CD(OH) l -C 6 h 2 -W (l=20, W=I) and polyether functionalized organic base R 1 (EO) n IMR 2 (R 1 =CH 3 , R 2 =H, n=16) dissolved in the organic solvent N,N-dimethylformamide (DMF), CD(OH) l -C 6 h 2 -W(l=20, W=I) and R 1 (EO) n IMR 2 (R 1 =CH 3 , R 2 =H, n=16) at a molar ratio of 1:3, reacted at 90°C for 84h. After the reaction, cool to room temperature, add acetone, filter, wash the filter cake three times with acetone, then wash twice with dichloromethane, and vacuum dry to obtain a light yellow solid powder with a yield of 79.5%.

Embodiment 2

[0056] Catalyst [R 1 (EO) n IMR 2 -C 6 h 2 CD(OH) l ][Y] synthesis (R 1 = Ph, R 2 =H, n=16, l=20, Y=Br - )

[0057] The β-cyclodextrin derivative CD(OH) l -C 6 h 2 -W (l=20, W=Br) and polyether functionalized organic base R 1 (EO) n IMR 2 (R 1 = Ph, R 2 =H, n=16) dissolved in the organic solvent N,N-dimethylformamide (DMF), CD(OH) l -C 6 h 2 -W(l=20, W=Br) and R 1 (EO) n IMR 2 (R 1 = Ph, R 2 =H, n=16) at a molar ratio of 1:3, reacted at 90°C for 84h. After the reaction, cool to room temperature, add acetone, filter, wash the filter cake three times with acetone, then wash twice with dichloromethane, and vacuum dry to obtain a light yellow solid powder with a yield of 77.8%.

Embodiment 3

[0059] Catalyst [R 1 (EO) n IMR 2 -C 6 h 2 CD(OH) l ][Y] synthesis (R 1 =CH 3 , R 2 =H, n=16, l=20, Y=Cl - )

[0060] The β-cyclodextrin derivative CD(OH) l -C 6 h 2 -W (l=20, W=Cl) and polyether functionalized organic base R 1 (EO) n IMR 2 (R 1 =CH 3 , R 2 =H, n=16) dissolved in the organic solvent N,N-dimethylformamide (DMF), CD(OH) l -C 6 h 2 -W (l=20, W=Cl) and R 1 (EO) n IMR 2 (R 1 =CH 3 , R 2 =H, n=16) at a molar ratio of 1:5, reacted at 90°C for 84h. After the reaction, cool to room temperature, add acetone, filter, wash the filter cake three times with acetone, then wash twice with dichloromethane, and vacuum dry to obtain a light yellow solid powder with a yield of 75.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com