Hole pressing and water spraying device and method for hole tray seeding

A water spraying device and hole tray technology, which is applied in planting methods, hole sowing seeders, automatic watering devices, etc., can solve the problem of difficulty in ensuring the accuracy of hole pressing or water spraying, low efficiency of hole pressing or spraying, and easy splashing To solve problems such as both sides of the tray, achieve the effect of reducing the start-stop time of the tray, high-quality pressing and watering operations, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

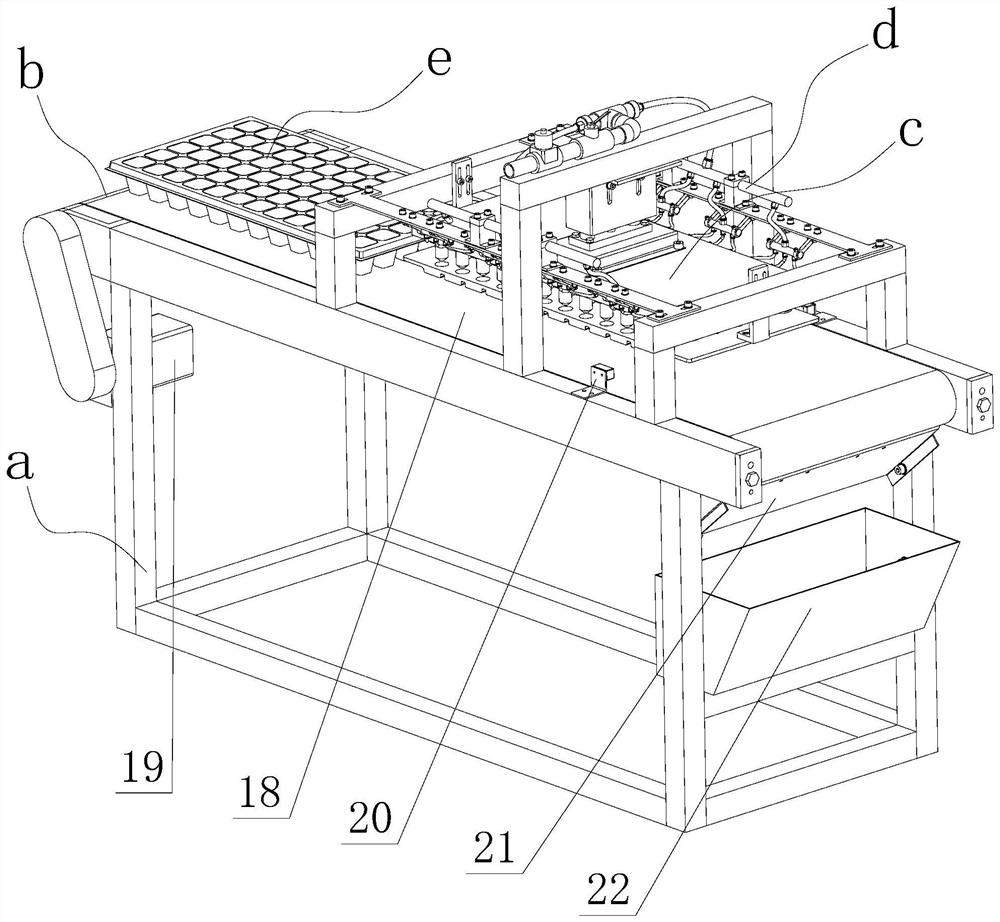

[0045] In this embodiment, a hole-pressing water spraying device for seeding in hole trays, its overall structure is as follows: figure 1 As shown, it includes the frame a, the hole tray conveying mechanism b, the hole pressure spray mechanism c and the water supply mechanism d. On the hole tray conveying mechanism; the hole pressing spray mechanism and the water supply mechanism are arranged across the top of the hole tray conveying mechanism, and the water supply mechanism is connected with the hole pressing spray mechanism. The specific structure of each constituent organization is as follows:

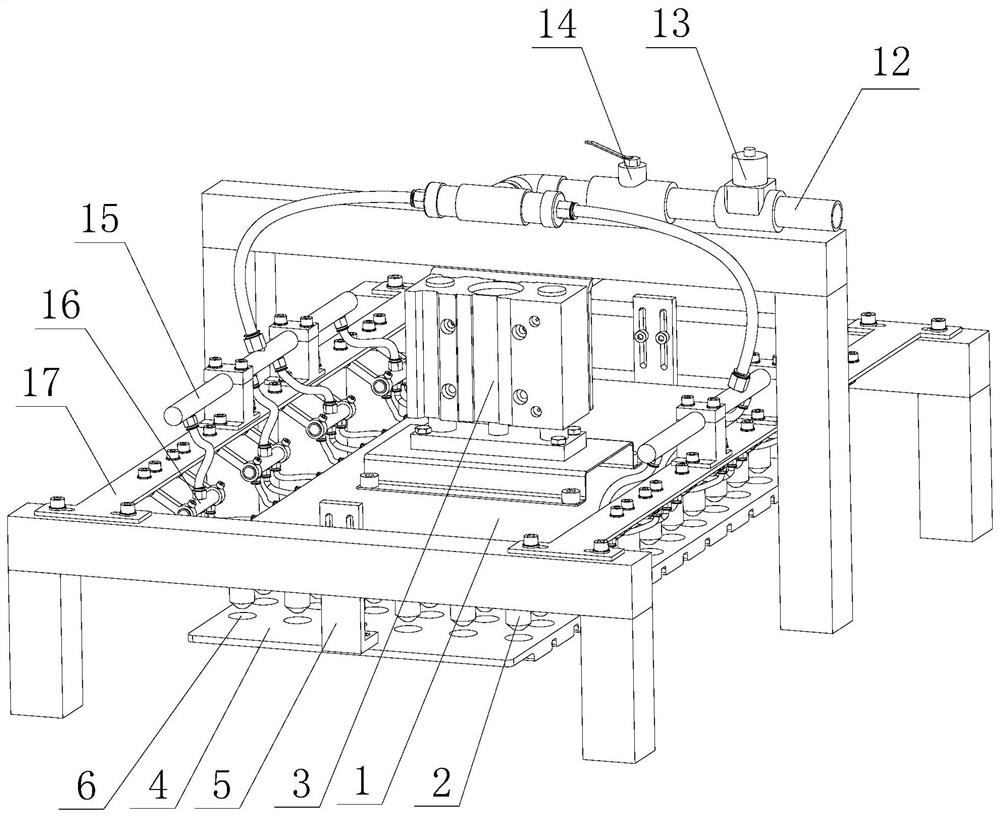

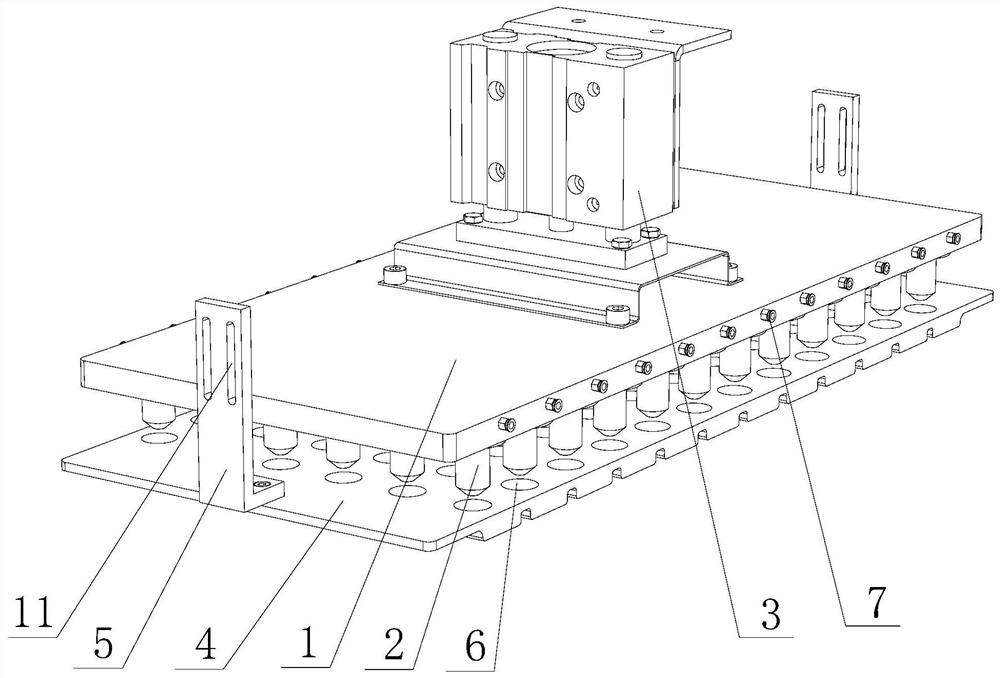

[0046] Such as figure 2 or image 3 As shown, the pressure hole spray mechanism includes a pressure hole spray plate 1, a pressure hole spray head 2, a linear lifting module 3, a hole plate limit plate 4 and a connecting plate 5. The linear lifting module is fixedly installed on the frame, and the straight line The lifting element of the lifting module is fixedly connected to th...

Embodiment 2

[0051] In this embodiment, a hole-pressing water spraying method for seeding in plug trays is realized by the hole-pressing water spraying device described in Embodiment 1. The method is as follows: the hole trays are sent to the bottom of the hole-pressing spraying mechanism by the plug tray conveying mechanism , the tray conveying mechanism first stops conveying; start the pressure hole spraying mechanism, and the matrix in each hole on the hole plate is pressed down by the pressure hole spraying head; Water is sprayed to the matrix in each hole on the hole plate through the hole-pressing spray head.

[0052] Wherein, when the hole plate positioning sensor detects the hole plate signal, the conveyor belt assembly stops moving, the pressure hole spray mechanism is located directly above the hole plate, and the center of each pressure hole spray head on it is consistent with the center of each hole of the hole plate , use the linear lifting module to drive the pressure hole sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com