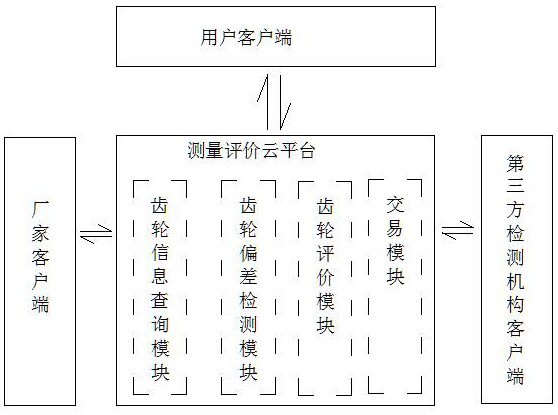

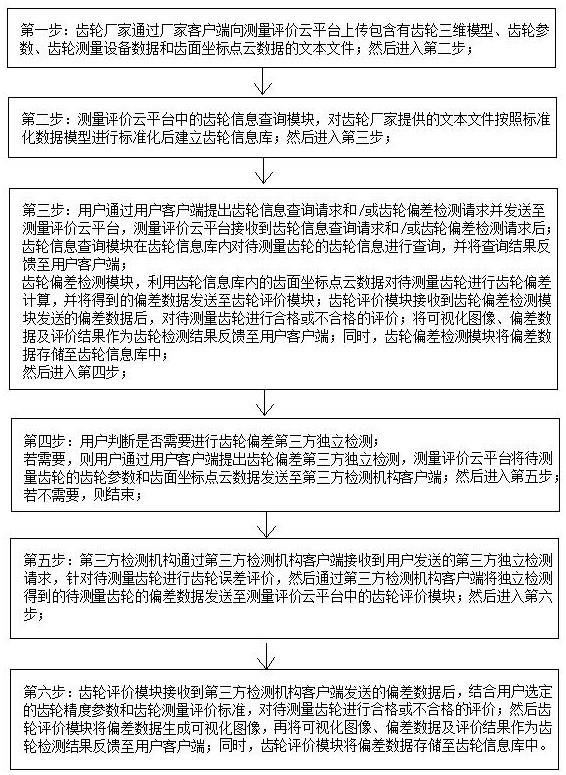

Gear digital measurement and evaluation cloud system and measurement and evaluation method

A gear measurement and cloud system technology, applied in manufacturing computing systems, electrical digital data processing, digital data information retrieval, etc., can solve problems such as gear manufacturing impact, untimely transmission, and untimely process feedback.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] When using the two-dimensional Chebyshev polynomial alone as the basis function to calculate the deviation surface equation of the gear to be measured, assuming that there are s tooth surface deviation point data in the tooth surface deviation point cloud data, using the least square method to solve the deviation surface equation is equivalent to The deviation surface equation is calibrated s times, that is, the best approximate surface after s calibrated is obtained.

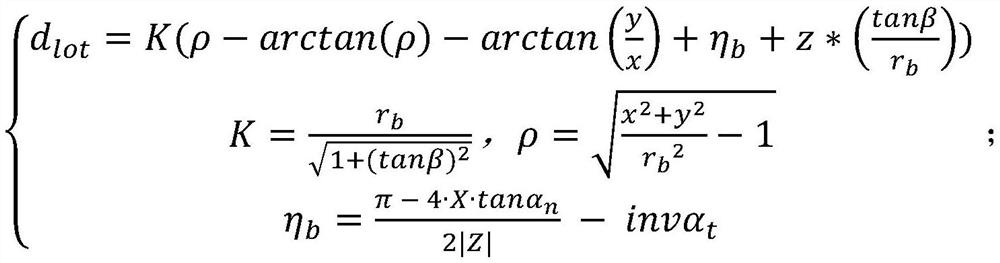

[0138] The following formula is a system of equations established by the method of least squares, and the deviation surface equation d is solved by this system of equations C :

[0139]

[0140] The deviation surface equation defined in the u′-v′-d tooth surface coordinate system is calculated by the two-dimensional Chebyshev polynomial as:

[0141] d C =A C0 *1+A C1 *u′+A c2 *v′+A C3 *(2u′ 2 -1)+A C4 *u′v′+A C5 *(2v′ 2 -1);

[0142] The specific proportional relationship between the deviatio...

Embodiment 2

[0144] When the two-dimensional Legendre polynomial is used alone as the basis function to calculate the deviation surface equation of the gear to be measured, assuming that there are s tooth surface deviation point data in the tooth surface deviation point cloud data, the least square method is used to solve the deviation surface equation. The deviation surface equation is calibrated s times, that is, the best approximate surface after s calibrated is obtained.

[0145] The following formula is a system of equations established by the method of least squares, and the deviation surface equation d is solved by this system of equations L :

[0146]

[0147] Find d through the two-dimensional Legendre polynomial L The equation of the deviation surface defined in the u′-v′-d tooth surface coordinate system is:

[0148]

[0149] The specific proportional relationship between the deviation item and the coefficient is: the tooth pitch deviation is equal to A L0 , the tooth p...

Embodiment 3

[0151] The two-dimensional Legendre polynomial and the two-dimensional Chebyshev polynomial are respectively used as the basis functions to obtain the corresponding deviation surface equations, and then according to the evaluation requirements for different types of tooth surface deviations, the coefficients of the corresponding deviation surface equations are selected to obtain more accurate Different types of tooth surface deviation evaluation results.

[0152] Assuming that there are s tooth surface deviation point data in the tooth surface deviation point cloud data, when the least square method is used to solve the deviation surface equation, it is equivalent to correcting the deviation surface equation s times, that is, the best approximate surface after s corrections is obtained .

[0153] The deviation surface equations obtained by using two-dimensional Chebyshev polynomials as basis functions are:

[0154] d C =A C0 *1+A C1 *u′+A C2 *v′+A C3 *(2u′ 2 -1)+A C4 *...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com