Energy-saving multi-chamber continuous drying boiling dryer

A boiling dryer, energy-saving technology, used in dryers, drying chambers/containers, drying solid materials, etc., can solve problems such as low drying efficiency, reduce waste, reduce energy, and improve drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The application discloses an energy-saving multi-chamber continuous drying fluidized dryer.

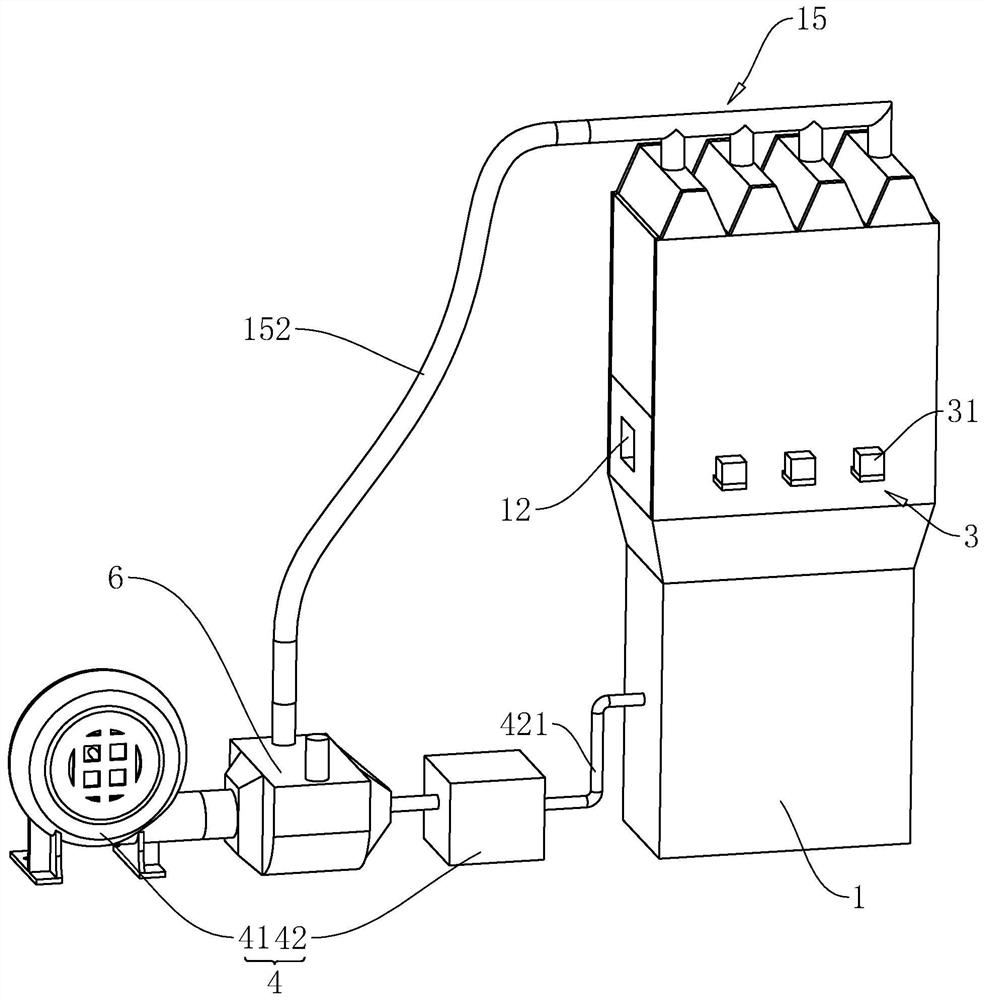

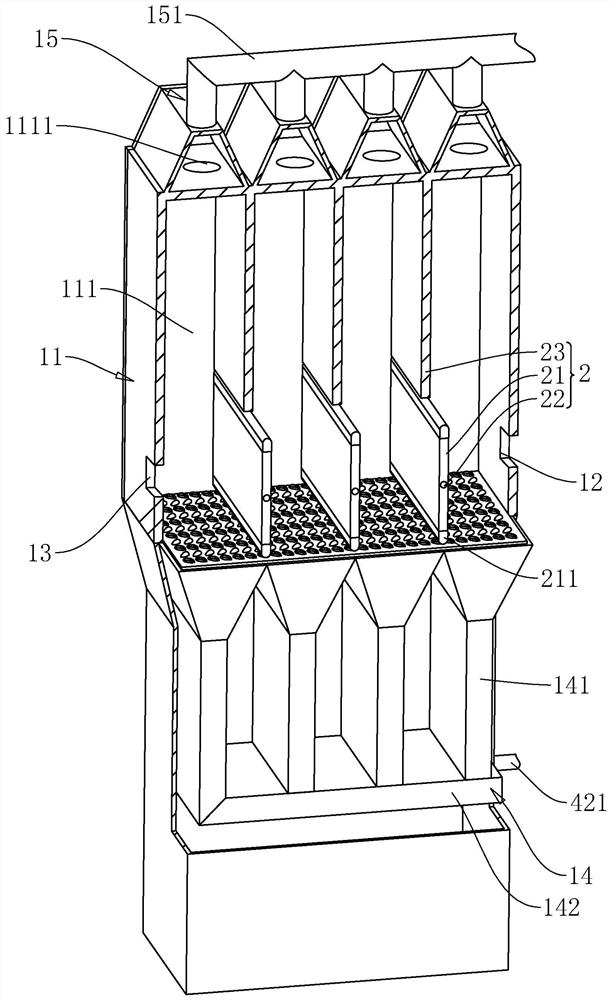

[0041] refer to figure 1 and figure 2 , an energy-saving multi-chamber continuous drying fluidized dryer includes a fluidized dryer body 1, a drying chamber 11 is provided in the fluidized dryer body 1, a partition device 2 is provided in the drying chamber 1, and the partition device 2 is arranged along the fluidized dryer body 1. There are multiple arrays in the width direction. The partition device 2 divides the drying chamber 11 into a plurality of drying sub-chambers 111. The fluidized dryer body 1 is connected with a feed port 12 and a discharge port 13. The feed port 12 and the discharge port 13 is oppositely arranged along the width direction of the fluidized dryer body 1, so that after the material enters from the feed port 12, it needs to pass through all the drying sub-chambers 111 before it can be discharged from the discharge port 13. The bottom of the fluidized d...

Embodiment 2

[0048] The application discloses an energy-saving multi-chamber continuous drying fluidized dryer.

[0049] The difference from Embodiment 1 is that the structure of the driving device 3 has changed.

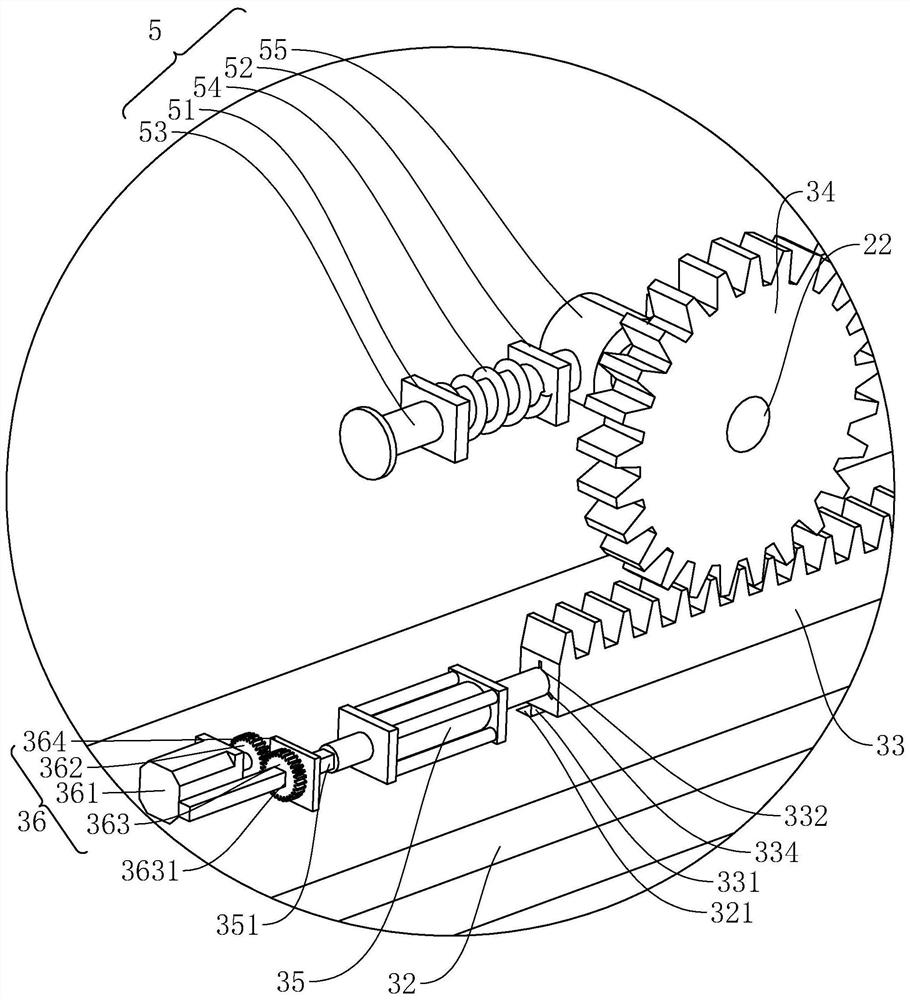

[0050] refer to image 3 and Figure 4 , the driving device 3 includes a fixed plate 32, a rack 33, a first gear 34 and a telescopic cylinder 35, the fixed plate 32 is fixed on the side wall of the fluidized dryer body 1, and the telescopic cylinder 35 is fixed on the fixed plate 32. One end of the rotating shaft 22 along its axial direction passes through the body 1 of the boiling dryer and is coaxially fixed with the first gear 34. The rack 33 meshes with the first gear 34. The end of the rack 33 facing the fixed plate 32 is fixedly connected with a slider 331 A chute 321 is opened on the fixed plate 32 along the width direction of the fluidized dryer body 1 , and the slider 331 is slidably connected in the chute 321 .

[0051] refer to Figure 4 , the fixed plate 32 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com