Drying device for green tea

A drying device, green tea technology, applied in the direction of tea processing before extraction, etc., can solve the problem of not removing the edges of tea leaves and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

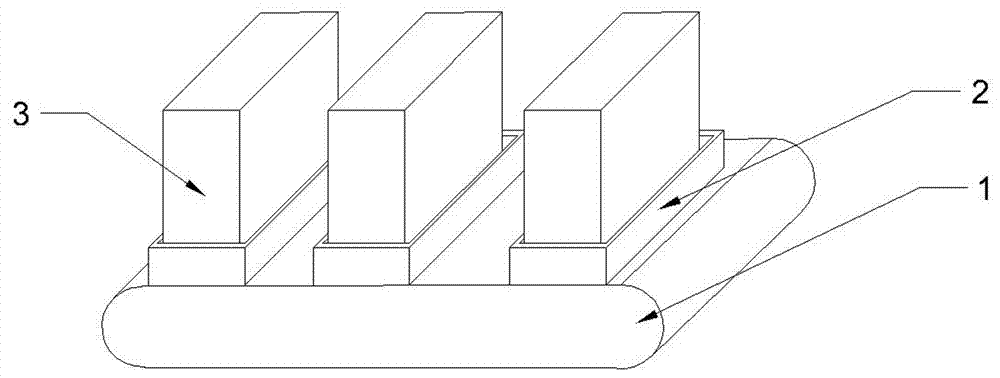

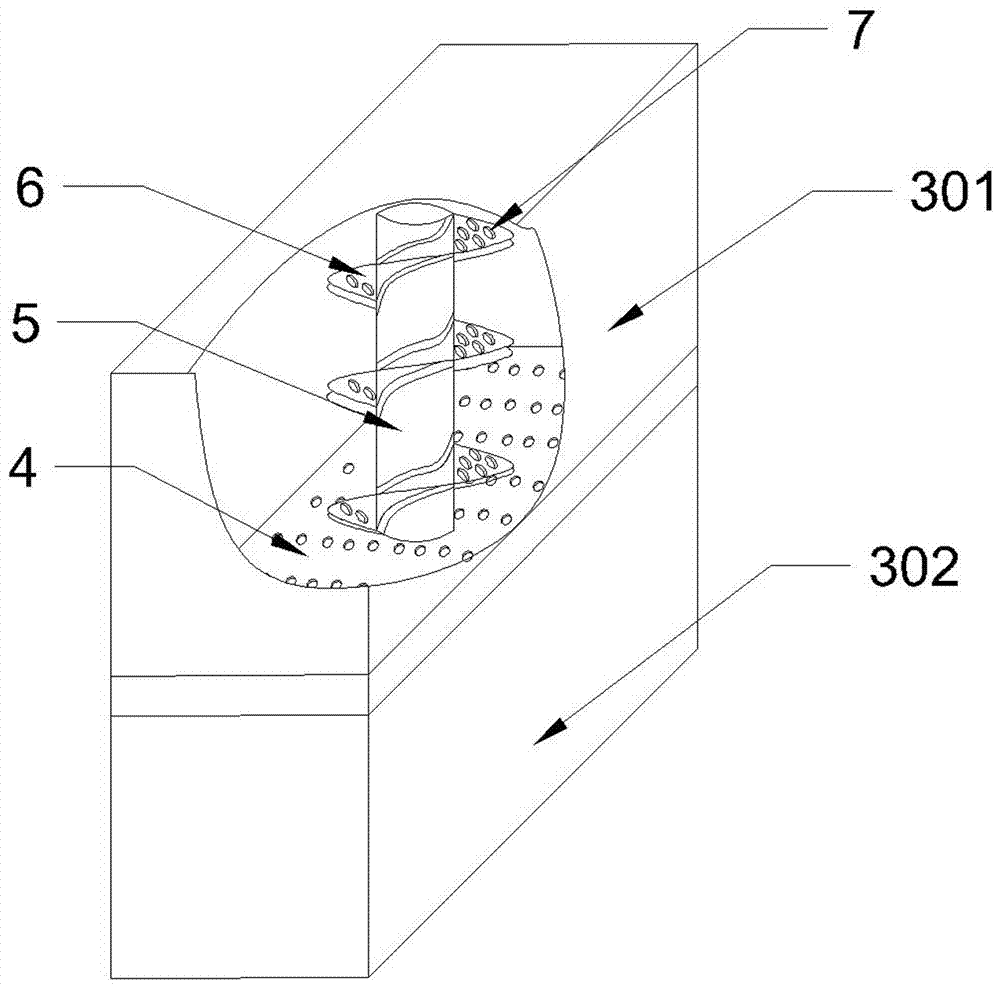

[0016] The reference signs in the drawings of the description include: conveyor belt 1 , card slot 2 , drying box 3 , slag holding box 302 , material holding box 301 , screen 4 , rotating shaft 5 , spiral blade 6 , and leakage hole 7 .

[0017] The embodiment is basically as attached figure 1 Shown: a drying device for green tea, including a drying room, a conveyor belt 1 installed in the drying room, the surface of the conveyor belt 1 is connected with a number of card slots 2, and the card slots 2 are evenly arranged on the conveyor belt 1 On the surface, the card slot 2 is fitted with a drying box 3; the drying device also includes a screening mechanism, the screening mechanism includes a screen 4 and a rotating shaft 5, the screen 4 is arranged in the middle of the drying box 3, and the screen 4 and the drying The bottom surface of the box 3 is parallel, and the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com