Magnetic levitation screw type gas expander

A gas expander and screw-type technology, which is applied in the direction of intermeshing engines, mechanical equipment, engine components, etc., can solve the problems of complex oil circuit circulation system, increased pressure drop of filter screen, and many components, so as to achieve performance and reliability Enhanced performance, elimination of increased pressure drop, zero leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

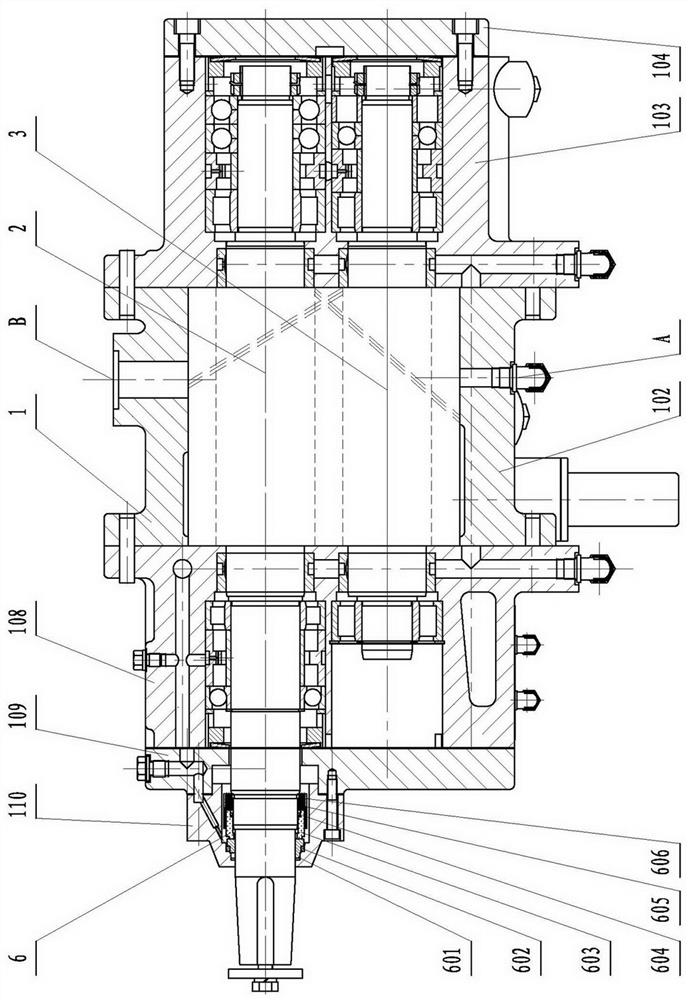

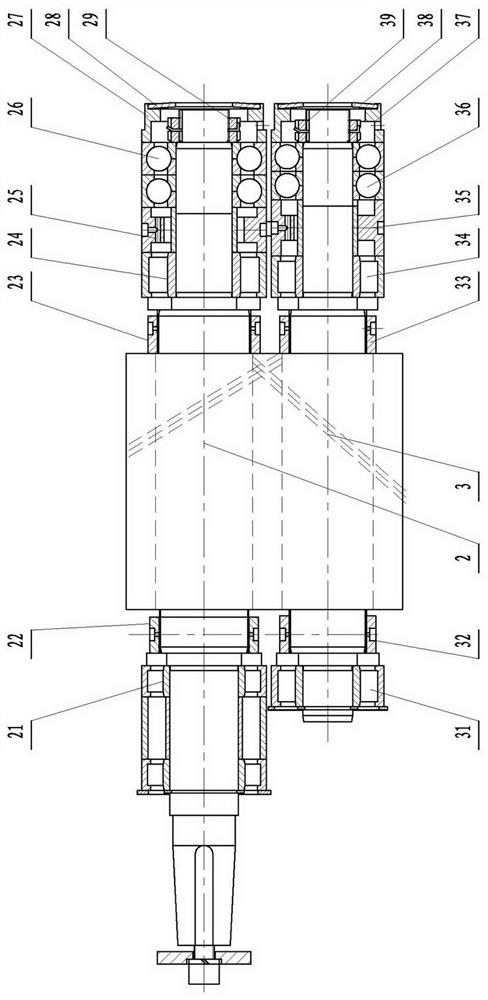

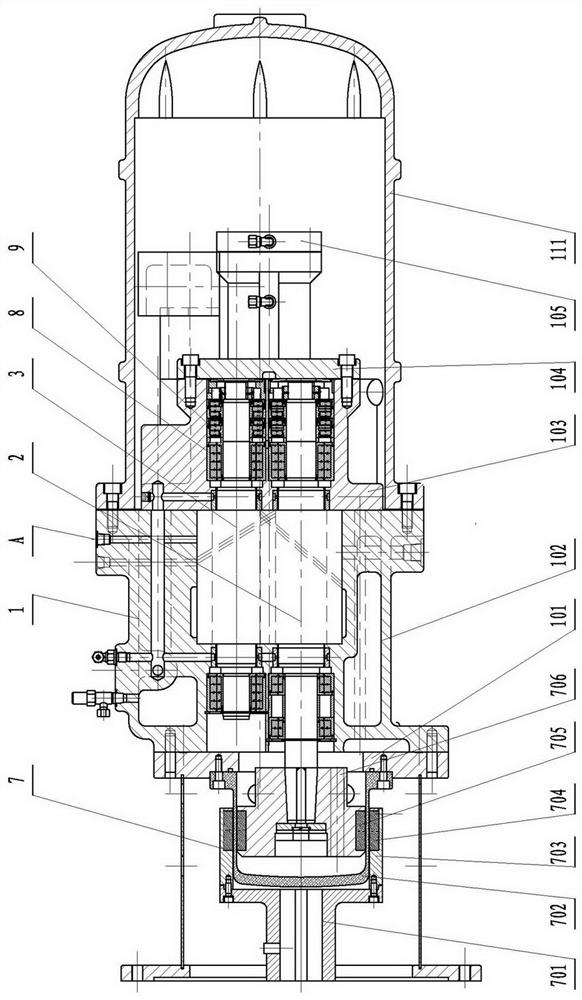

[0041] exist image 3 , 4 , 5, and 6 show an embodiment of a magnetic levitation screw type gas expander, at least composed of a body part 1, a driving rotor 2, a driven rotor 3, a magnetic coupling 7, a radial permanent magnetic bearing 8 and a bidirectional permanent magnet Parts such as the axial thrust bearing 9 form a whole.

[0042] The connecting body 101, the body 102, the air inlet end seat 103, the air inlet end cover 104, the end cover 105, and the muffler 111 are connected into body parts by screws;

[0043]Drive rotor 2, radial permanent magnetic bearing 201 at the exhaust end of the drive rotor, hub 22 at the exhaust end of the drive rotor, hub 23 at the intake end of the drive rotor, radial permanent magnet bearing 202 at the intake end of the drive rotor, intake air of the drive rotor The end gap adjustment ring 203, the two-way permanent magnet axial thrust bearing 204 at the intake end of the driving rotor, the bearing gland 27 at the intake end of the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com