A kind of coating device and preparation process of graphene heat sink

A technology for coating devices and heat sinks, which is applied to devices for coating liquids on surfaces, coatings, and cleaning methods using tools, etc., can solve problems affecting the adhesion between heat sinks and electronic components, and uneven thickness of graphene films. , to achieve the effect of reducing labor costs, improving flatness and aesthetics, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

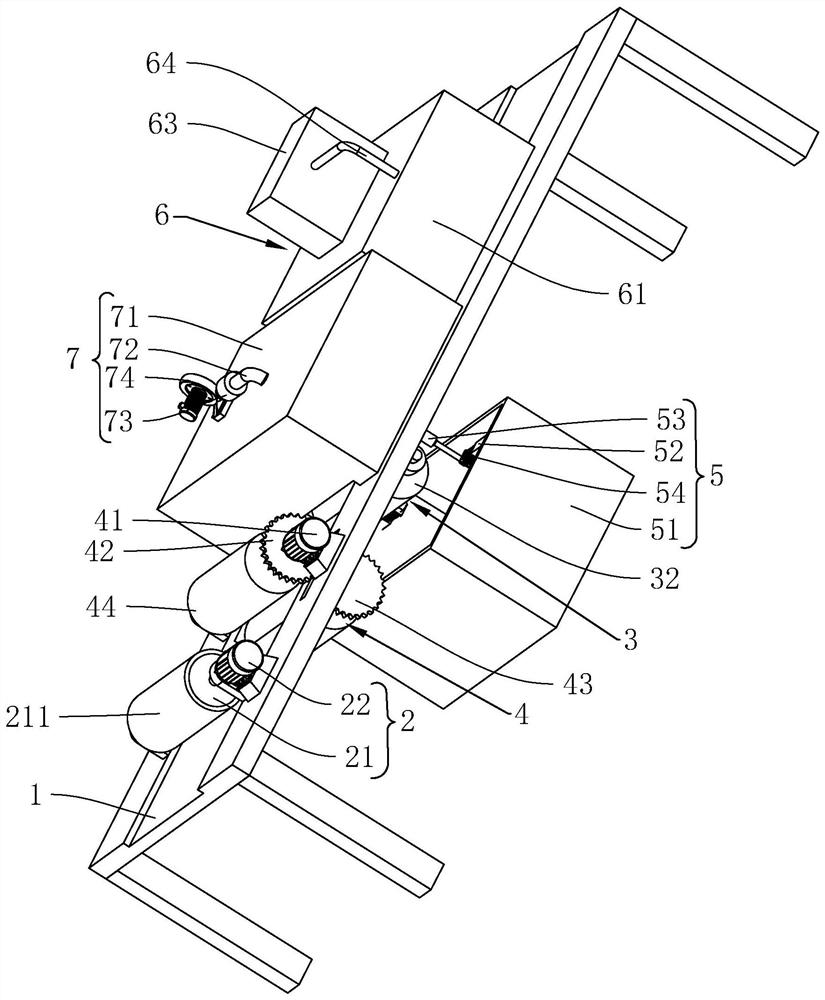

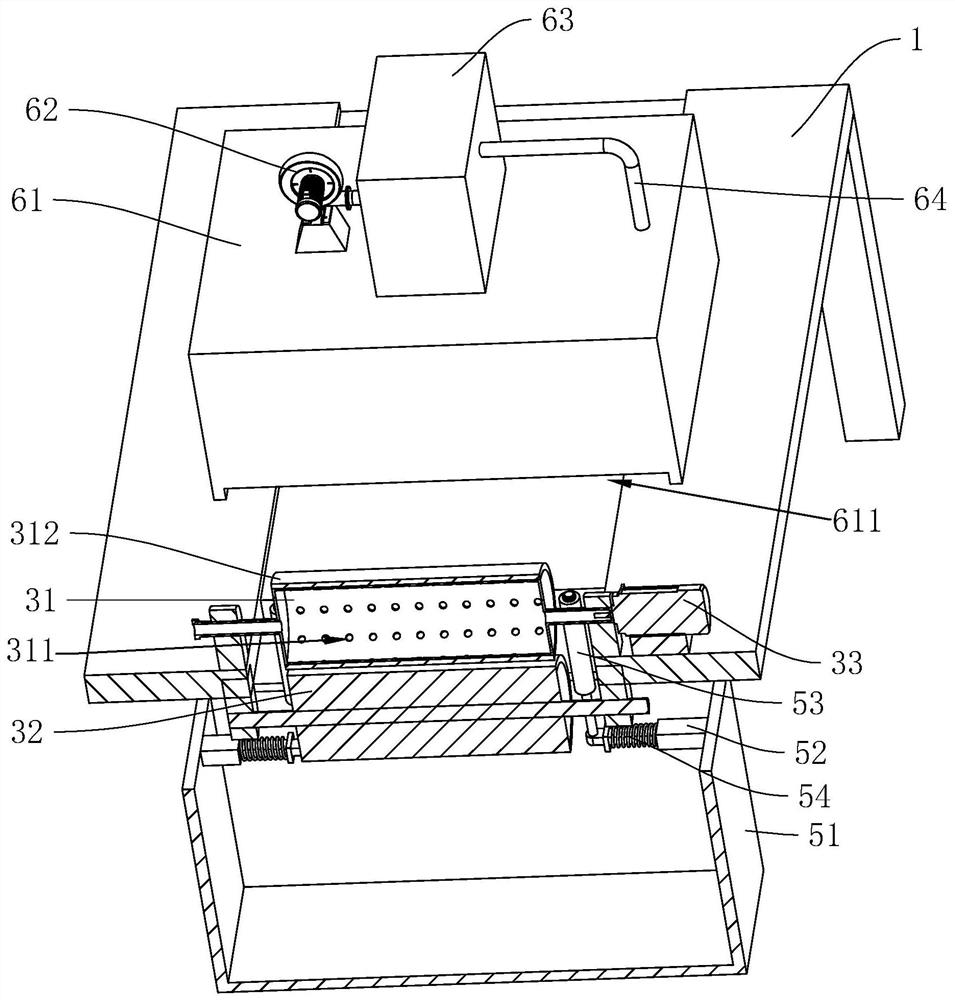

[0037] The following is attached Figure 1-2 The present invention is described in further detail.

[0038] In the first aspect, the embodiment of the present invention discloses a coating device for a graphene heat sink. refer to figure 1, the coating device of the graphene heat sink comprises a workbench 1, a cleaning component 2, a coating component 3, a flattening component 4, a drying component 6 and a dust removal component 7, a cleaning component 2, a flattening component 4, and a coating component 3 , the scraping member 5, the drying member 6 and the dust removal member 7 are all located on the workbench 1, and the cleaning member 2 is convenient for cleaning the heat sink, improves the cleanliness of the heat sink, and reduces the influence of dust on graphene coating; flattening The setting of component 4 is convenient to flatten the cooling fins, improve the flatness of the cooling fins, and reduce the influence on the thickness of the graphene coating; the setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com