Nuclear power station shaft seal main pump motor rotor core pressing and shrinkage fit process method and process equipment thereof

A rotor core and motor rotor technology, which is applied in the manufacture of motor generators, electromechanical devices, stator/rotor bodies, etc., can solve the problems of length deviation, unsatisfactory, rotor pressure plate separation, etc., to eliminate the problem of axial clearance , Eliminate the effect of iron core loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A nuclear power plant shaft seal main pump motor rotor core pressurization and thermal sleeve process and its process equipment. First, the rotor core is loaded with process equipment, and the rotor core is heated and the shaft is thermally sleeved. The thermal sleeve adopts a vertical The installation method specifically includes the following process steps:

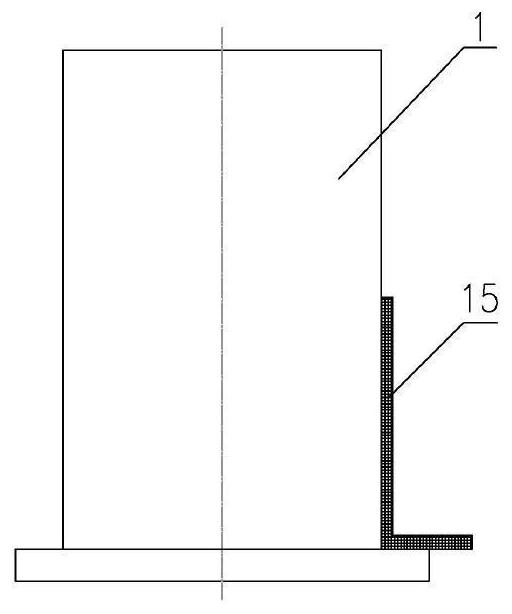

[0025] 1) if figure 1 As shown, install and adjust the core tire 1 and detect the diameter and verticality of the core tire 1. Use an outer micrometer to measure the diameters φ1, φ2, and φ3 of the core core 1 at the top, middle and bottom, and measure 2 sets of data in the cross direction of each diameter. , to judge the deviation of diameter and roundness, it must meet the technical requirements of the drawings; measure the verticality of the core tire 1 with a square 15, keep the bottom edge of the square 15 fit without gaps, and observe the other right-angled side of the square 15 and the outside of the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com