Motor sealing assembly and motor

A technology for sealing components and sealing parts, which is applied to electric components, cable entry sealing devices, electrical components, etc., can solve problems such as sealing failure, and achieve the effects of improving sealing performance, simple installation, and easy popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

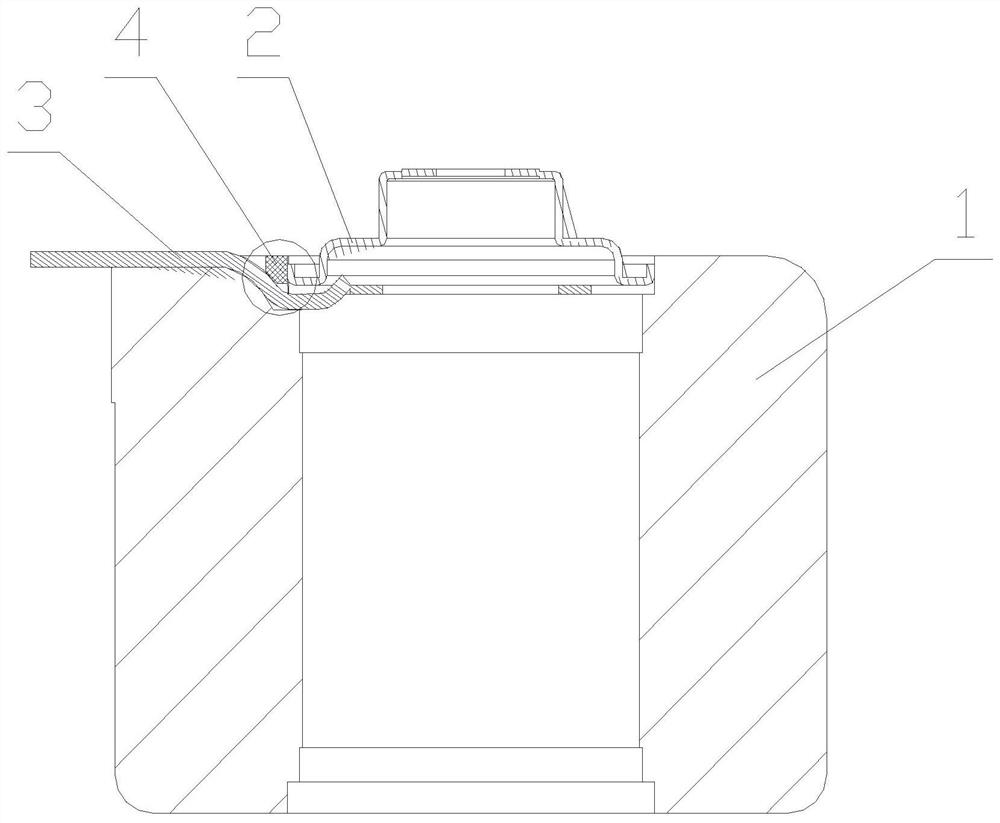

[0032] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, a motor sealing assembly is used to seal the wire hole through which the wire 3 passes between the stator 1 and the end cover 2, including:

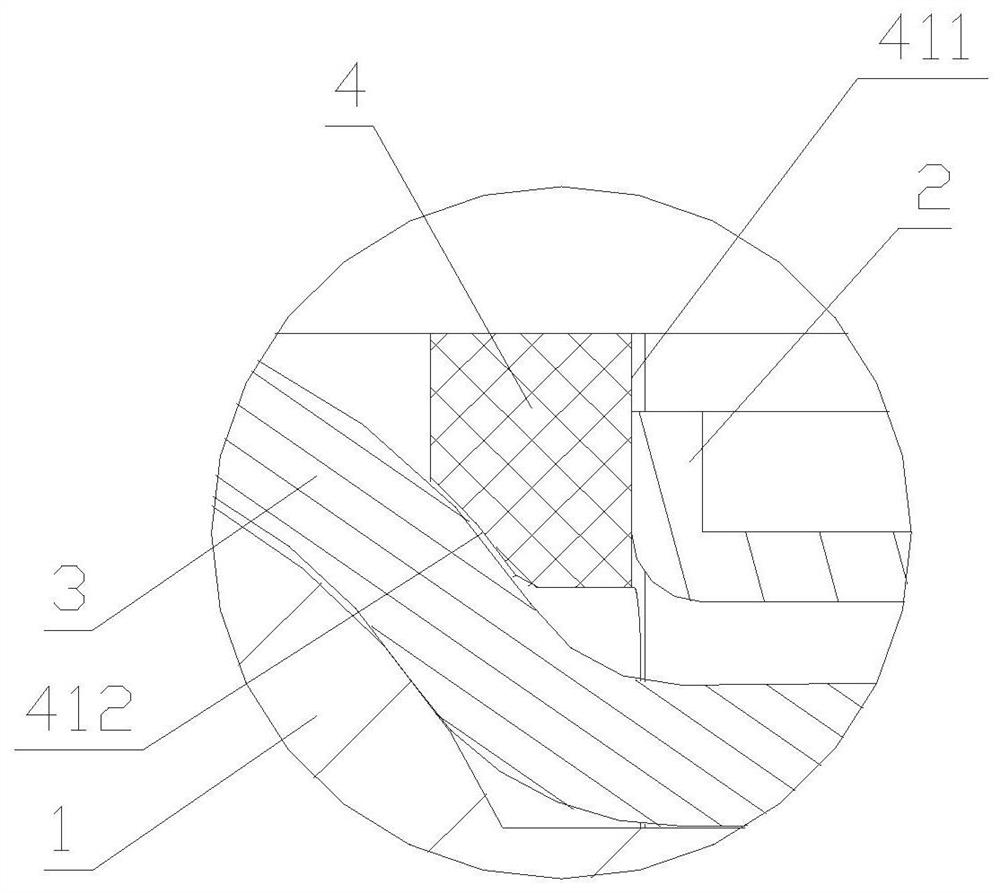

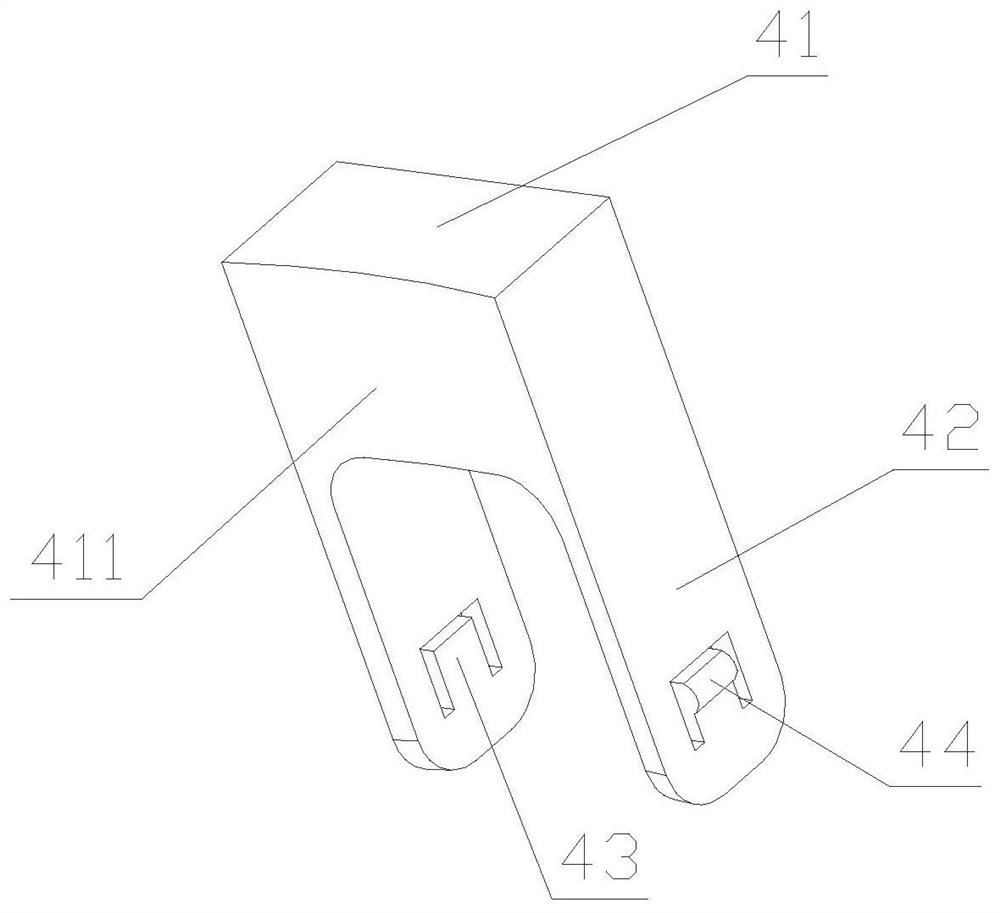

[0033] The sealing member 4 includes a connecting bridge 41, and the connecting bridge 41 spans the wire 3 in a bridge type;

[0034] The connection bridge 41 includes a first side 412 and a second side 411 , the first side 412 is in sealing contact with the wire 3 , and the second side 411 is in sealing contact with the end cap 2 .

[0035] Based on the fact that when the wire 3 passes through the wire hole between the stator 1 and the end cover 2, there will be a large gap between the wire 3 and the end cover 2, the application adds a bridge across the wire 3 at the gap. The sealing member 4 is provided with two side surfaces on the connecting bridge 41 included in the sealing member 4, and is in sealing contact with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com