Metal plate welding seam detection device and detection method

A welding seam detection and metal plate technology, which is applied in the field of metal plate welding seam inspection devices, can solve the problems of affecting accuracy, horizontal side leakage, complex structure, etc., and achieves the effect of improving accuracy and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

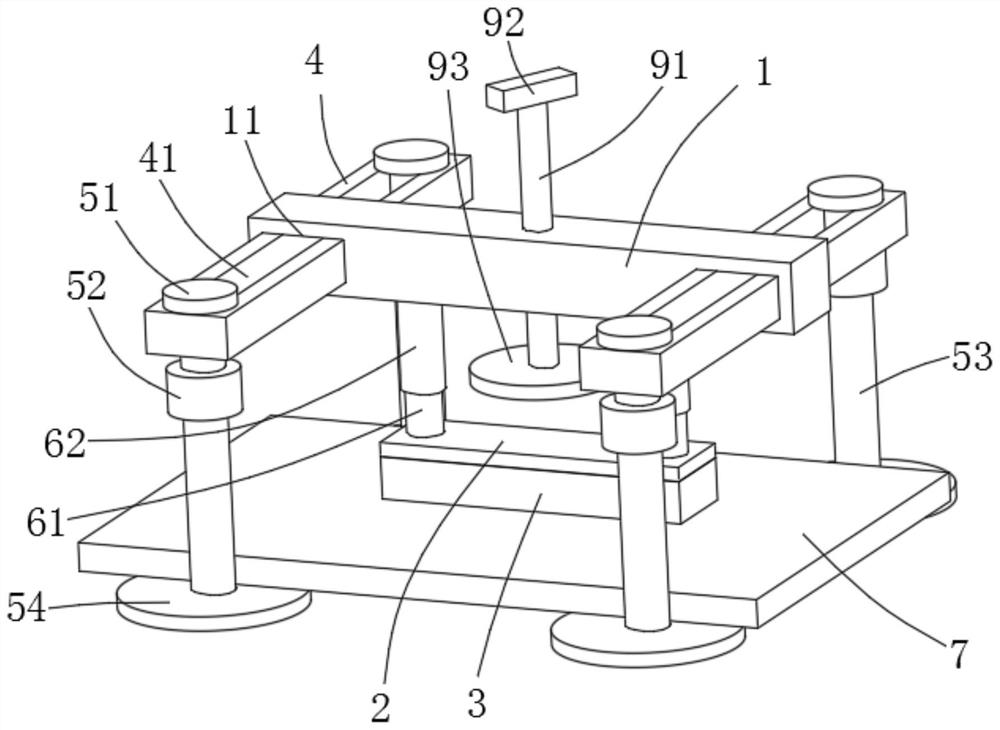

[0030] Embodiment: a metal plate weld detection device, such as Figure 1-2 As shown, it includes a slide block 1, a pressure plate 2, a sealing gasket 3 and a downward pressure driving mechanism that drives the pressure plate 2 to descend. The two ends of the slide block 1 are respectively connected with two connecting rods 4, and the two connecting rods 4 The end is equipped with a fixed claw, the slider 1 is connected with several elastic positioning rods, the elastic positioning rods are connected with the pressure plate 2, the lower surface of the pressure plate 2 is fixed with the sealing gasket, and the sealing gasket is located above the weld of the metal plate 7;

[0031] The slider 1 is provided with a slide hole 11 matched with the connecting rod 4 to allow the slider 1 to slide along the direction of the connecting rod 4, and the connecting rod 4 is provided with The matching chute 41 makes the two fixed claws close to or far away from each other, the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com