Water turbine top cover bolt looseness detection system and design method of detector

A technology of bolt loosening and detection system, which is applied in mechanical equipment, machine/engine, hydroelectric power generation, etc. It can solve the problems that it is difficult to meet the requirements of 80 bolts monitoring and the sensor is difficult to detect, and achieve low cost, long transmission distance, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

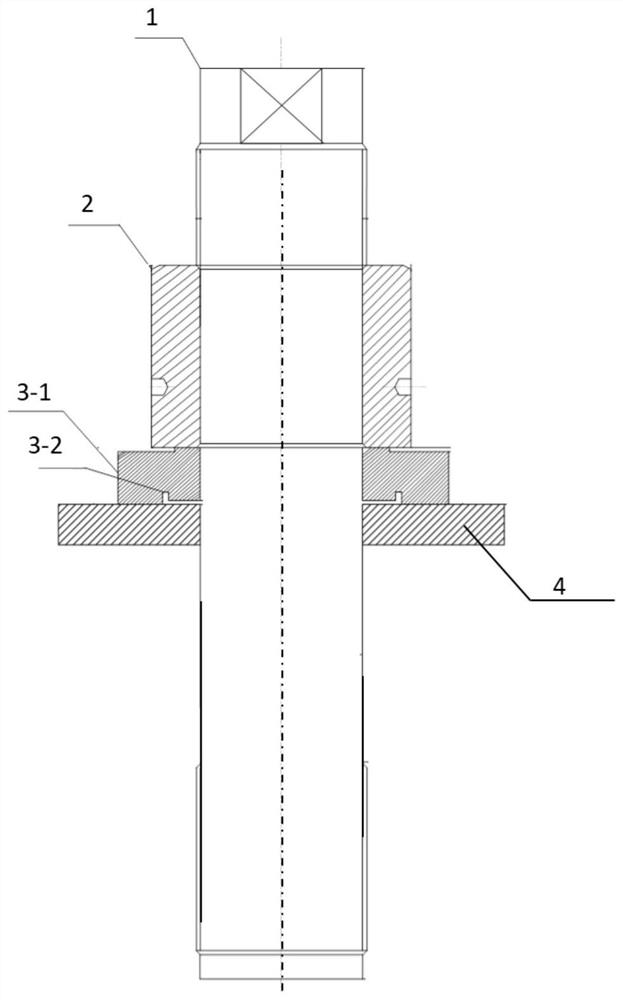

[0053] Such as Figure 1-6 As shown, a water turbine top cover bolt loose detection system is used to realize the loose detection and alarm for the water turbine top cover bolts; Corresponding to the fixed connection of the nut 2; the detection system for the loosening of the bolts on the top cover of the turbine, including a strain gauge pressure detector 3, a wireless transmitter and a diagnostic alarm unit.

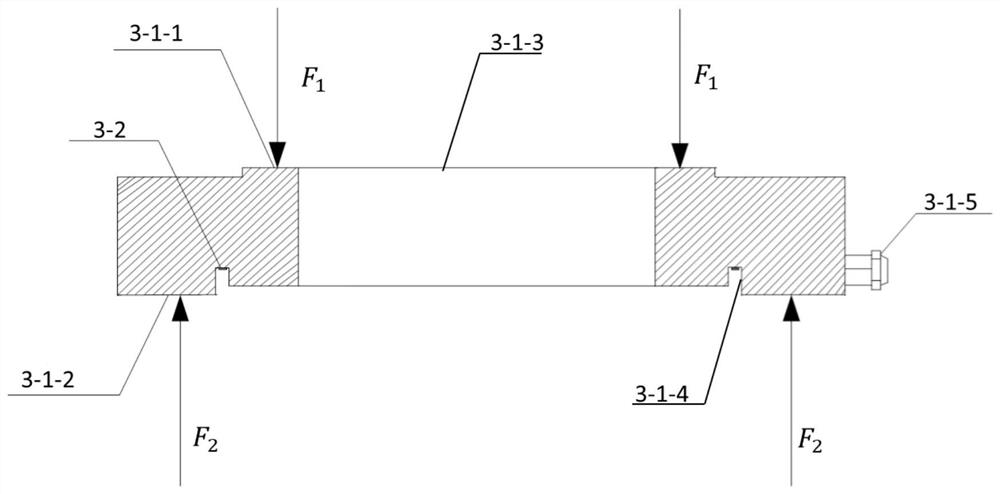

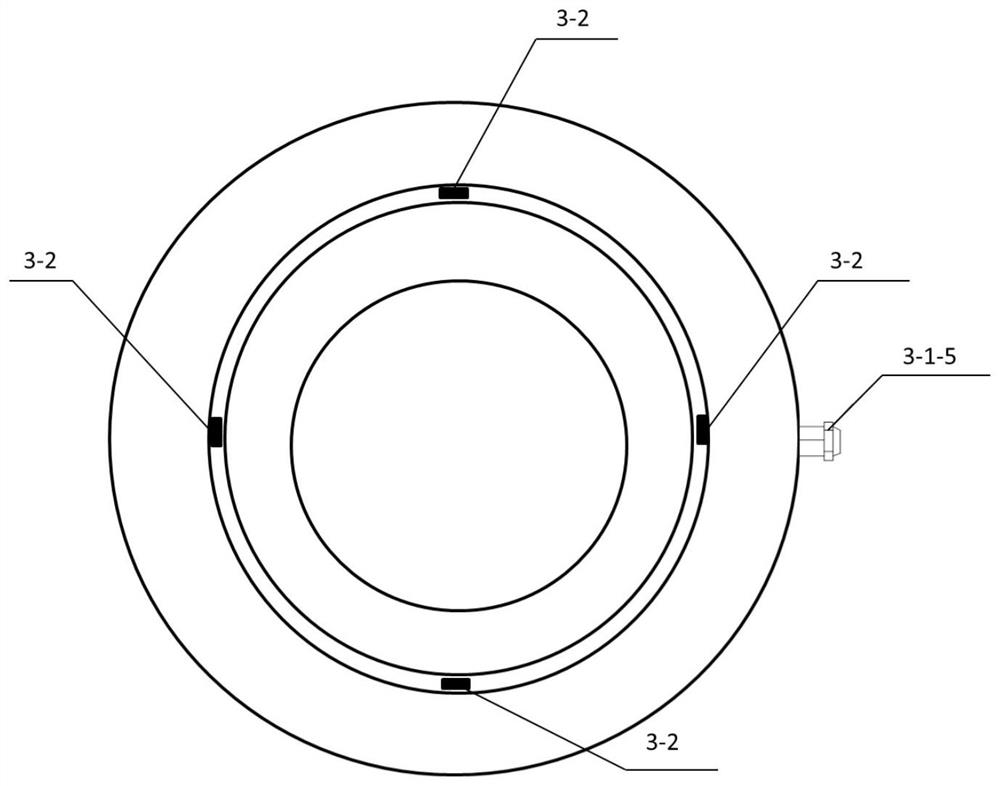

[0054] Among them, the strain gauge pressure detector 3 is arranged one-to-one with the closing bolt 1; the strain gauge pressure detector 3 collects the pretightening force of each closing bolt 1 in real time; the strain gauge pressure detector 3 is a gasket type pressure sensor, Including the gasket body 3-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com