Dredged bottom mud solidification modification method

A technology for dredging and modifying sediment, which can be used in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc., and can solve problems such as low volume expansion ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

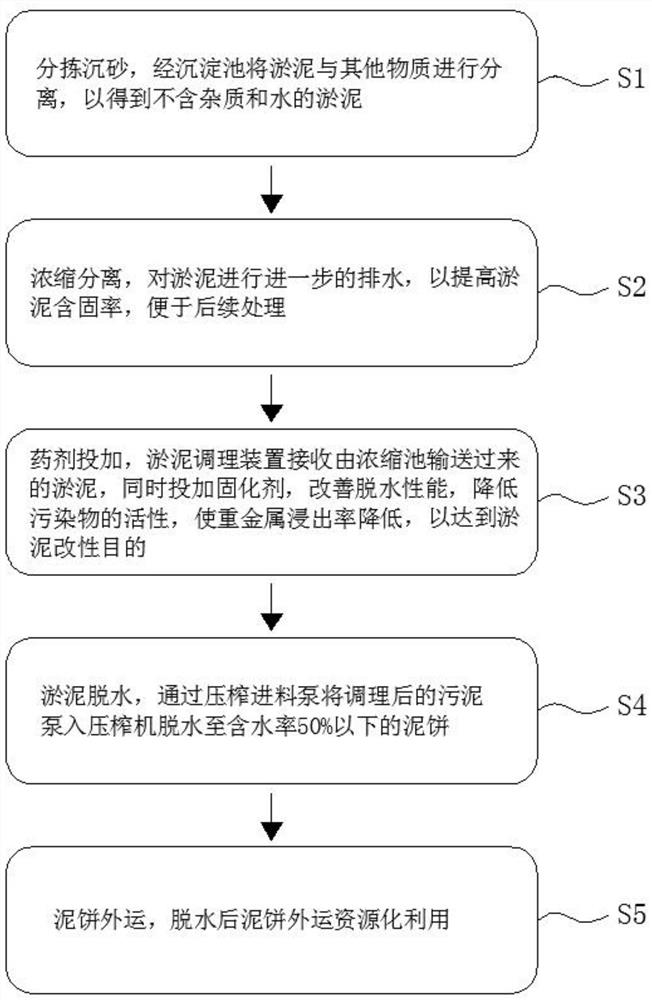

[0036] See figure 1 , Dredged mud curing modification method, including the following steps:

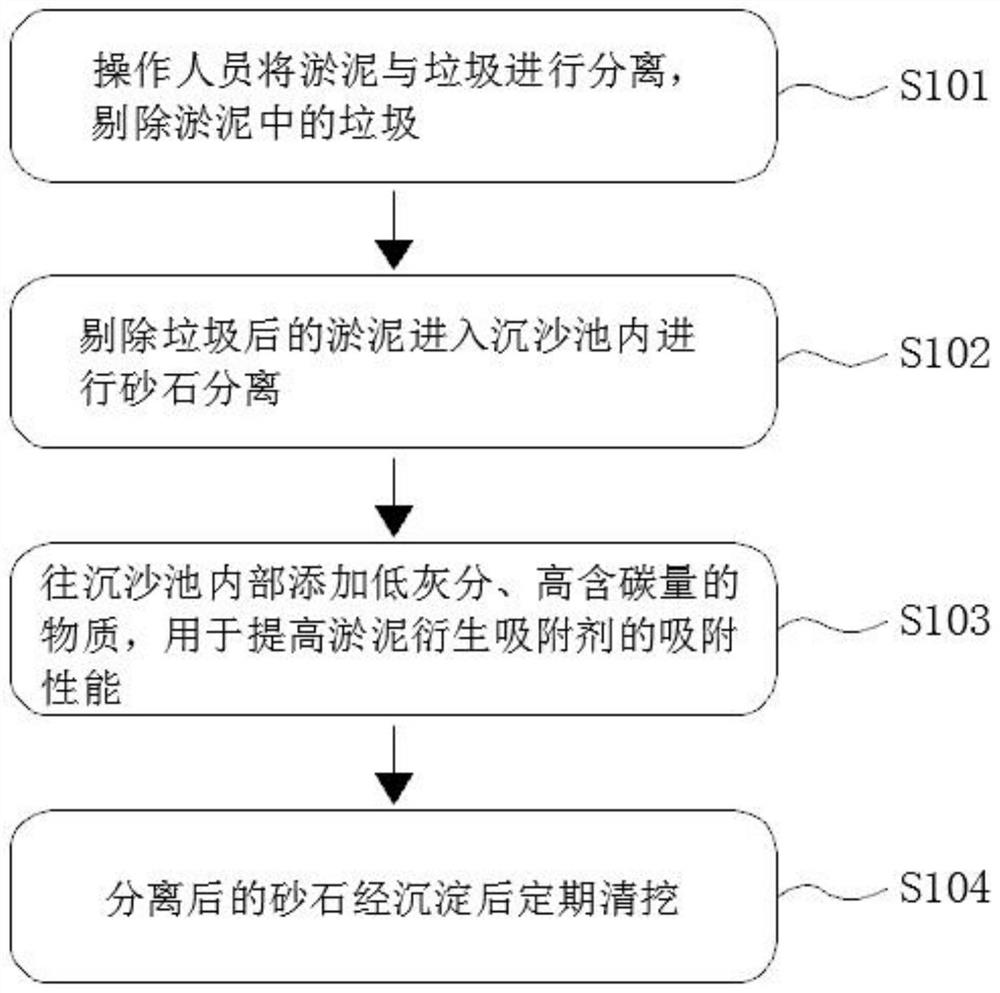

[0037] Step 1: Sorting sand, separating the sludge with other substances by the sedimentation tank to obtain a silt that does not contain impurities and water;

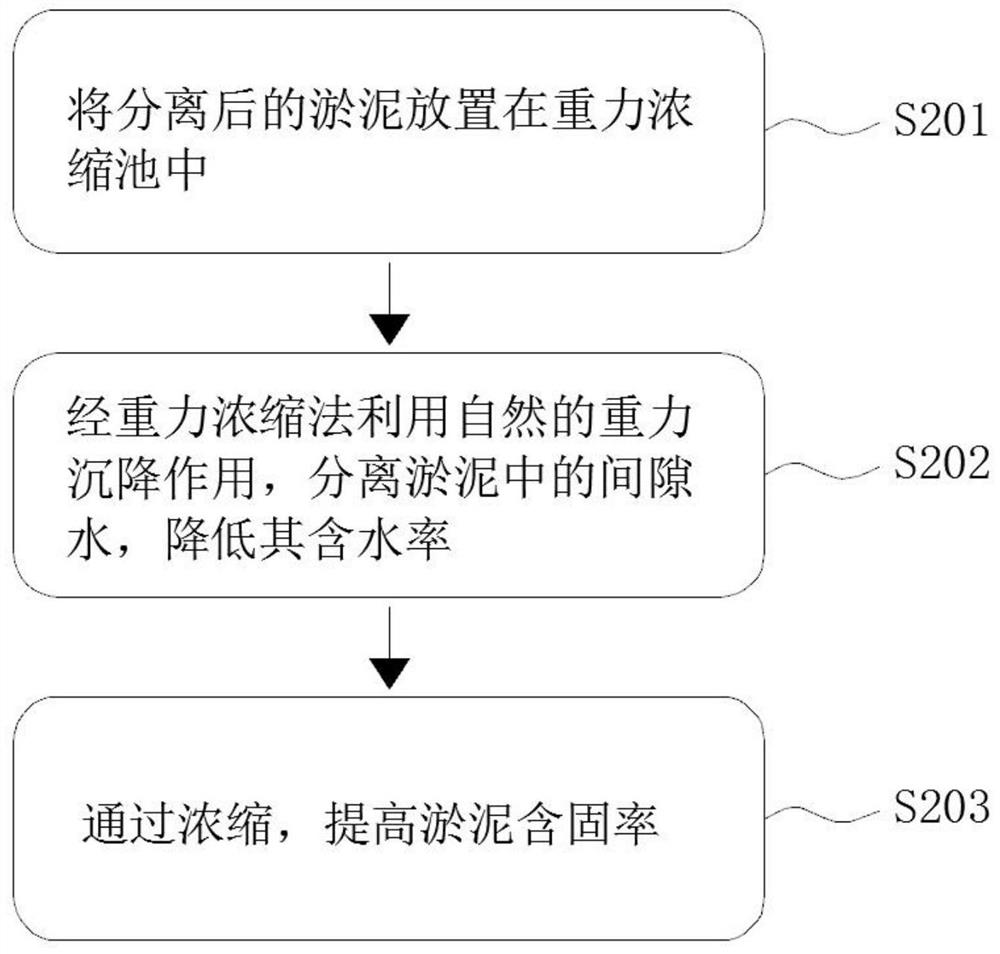

[0038] Step 2: Concentrate separation, further drain on the mud to improve the mud-containing curing rate, which is convenient for subsequent treatment;

[0039] Step 3: The drug is added, the sludge conditioning device receives the silt mud delivered by the concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com