Junction box welding rapid assembly device for aerospace

A technology for aerospace and junction boxes, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as welding deformation, inability to locate, and difficulty in ensuring the angle and position of parts, so as to improve rigidity and strength, improve Finished product quality, the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

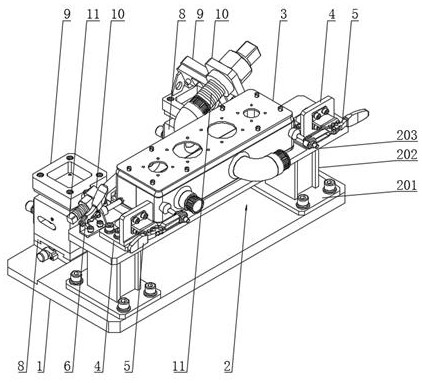

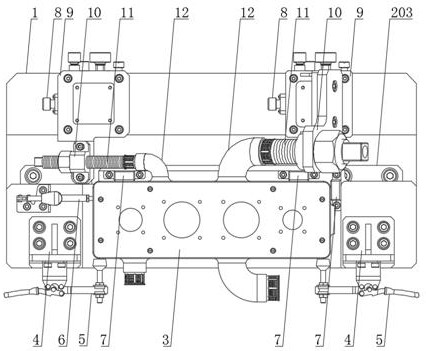

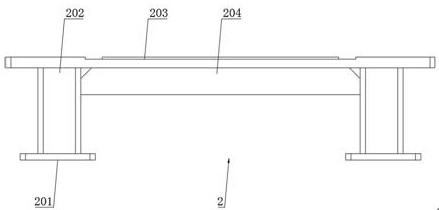

[0020] Example: see Figure 1-Figure 3 , the present invention provides a kind of junction box welding rapid assembly device for aerospace, comprising a base 1, the top of the base 1 is fixedly installed with a welding platform 2, the welding platform 2 includes a foot seat 201 fixed on the top of the base 1, and the foot The stand 202 fixedly connected to the top of the seat 201 , and the flat plate 203 fixedly connected to the top of the stand 202 and placed with the junction box 3 . The foot 201 and the foot 202 are integrally formed, the horizontal section of the foot 202 is I-shaped, the center of the foot 202 is provided with a lightening hole, the horizontal section of the lightening hole is circular, and the top of the foot 202 is detachably connected to the flat plate 203 by bolts. Two left and right feet 202 are provided. The bottom of the plate 203 is integrally formed with cooling fins 204 . On the one hand, the heat dissipation fins 204 increase the heat dissipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com