Vacuum mixer for intelligent material supply and distribution equipment

A vacuum mixer and batching equipment technology, which is applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve the problems that the cylinder is difficult to reach a vacuum state, gas and water cannot be discharged, and the degree of uniformity of mixing is poor. Achieve high stirring efficiency, increase efficiency and effect, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

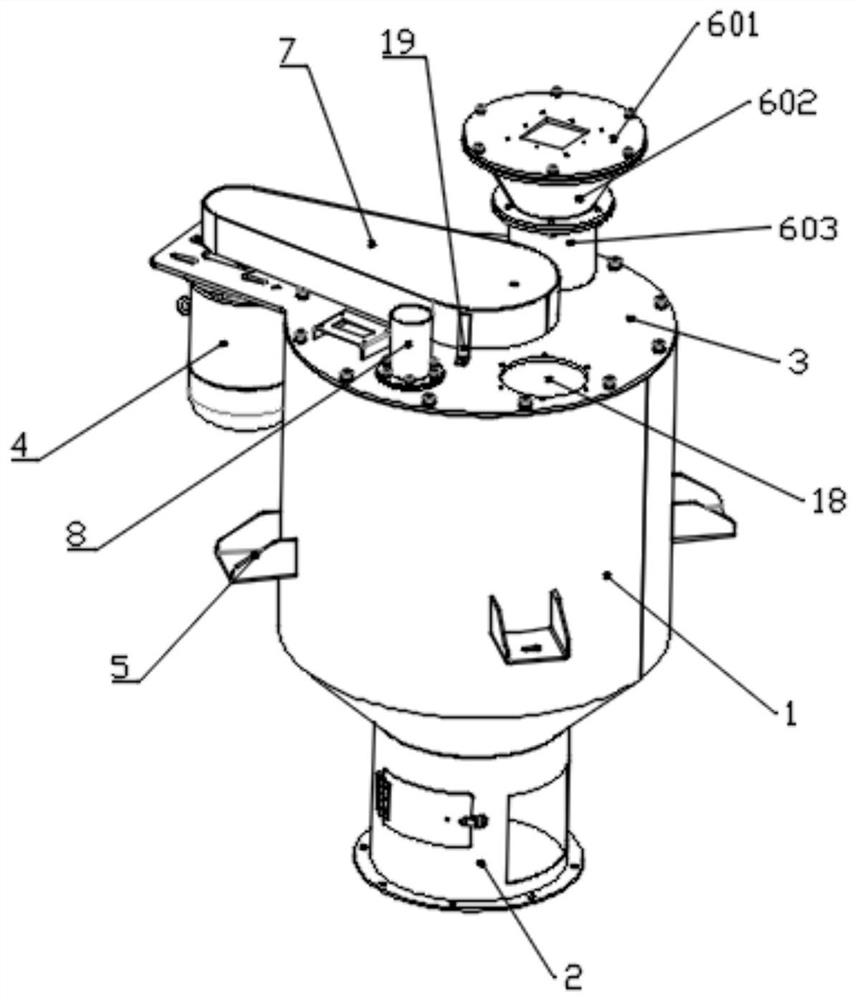

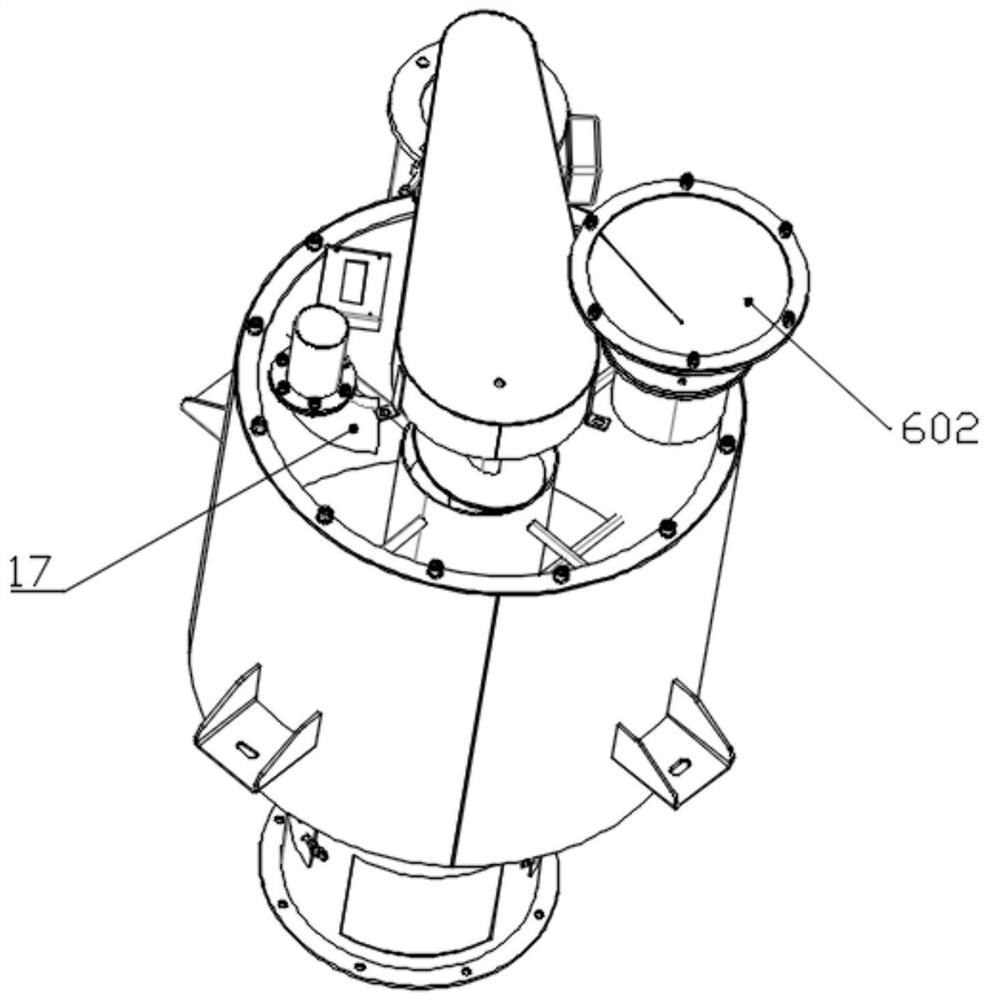

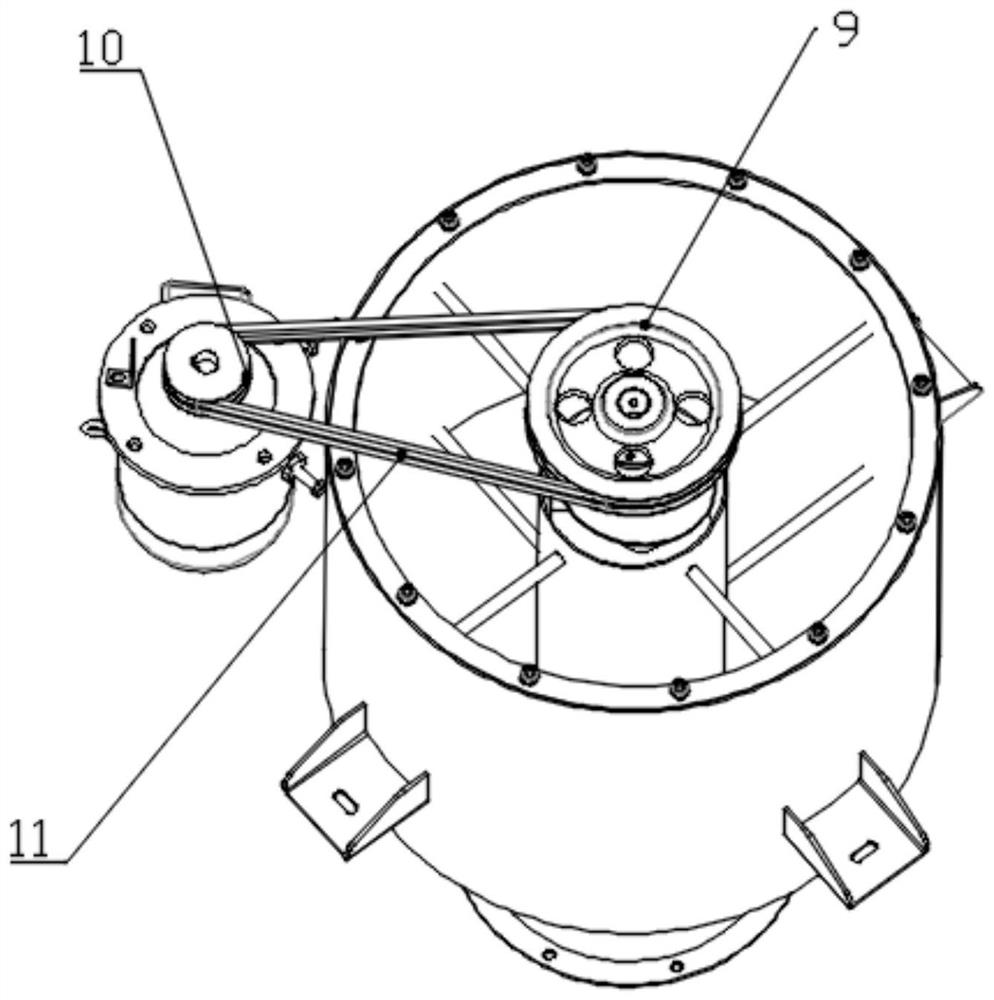

[0034] refer to Figure 1 to Figure 6 The shown vacuum mixer for intelligent batching equipment includes a cylinder 1, a cone base 2, a motor 4, a screw shaft 14, a feeding structure and a vacuuming structure, the cylinder 1 is connected to the cone base 2, and the The upper end of cylinder body 1 is provided with cover plate 3, and motor 4, screw shaft 14 are fixed on the cover plate 3, and the upper end of described motor 4, screw shaft 14 is respectively equipped with small pulley 10, big pulley 9, small pulley 10. A belt 11 is connected between the large pulleys 9. A guide bucket 12 is provided inside the cylinder body 1. The guide bucket 2 is a cylindrical structure. The guide bucket 12 is arranged along the axial direction of the cylinder body 1. The screw shaft 14 is formed by The middle of the guide barrel 12 passes through, and a support rod 13 is provided between the guide barrel 12 and the cylinder body 1. There are many support rods 13, and the support rods 13 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com