Assembling device of carbon brush holder for automobile and using method of assembling device

A technology for assembling devices and carbon brush holders, which is applied in the manufacture of brushes, rotating current collectors, electrical components, etc., can solve the problems of low installation accuracy, abnormal operation of carbon brushes, and difficult to grasp the size, so as to improve the use efficiency, Reduce vibration and install precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

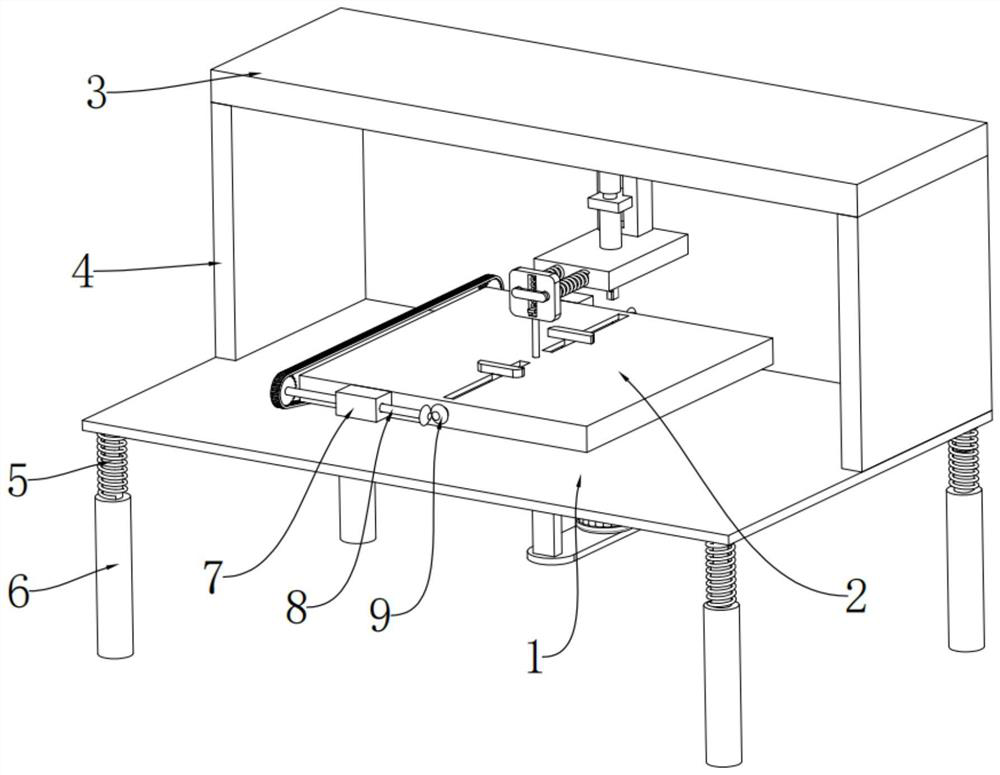

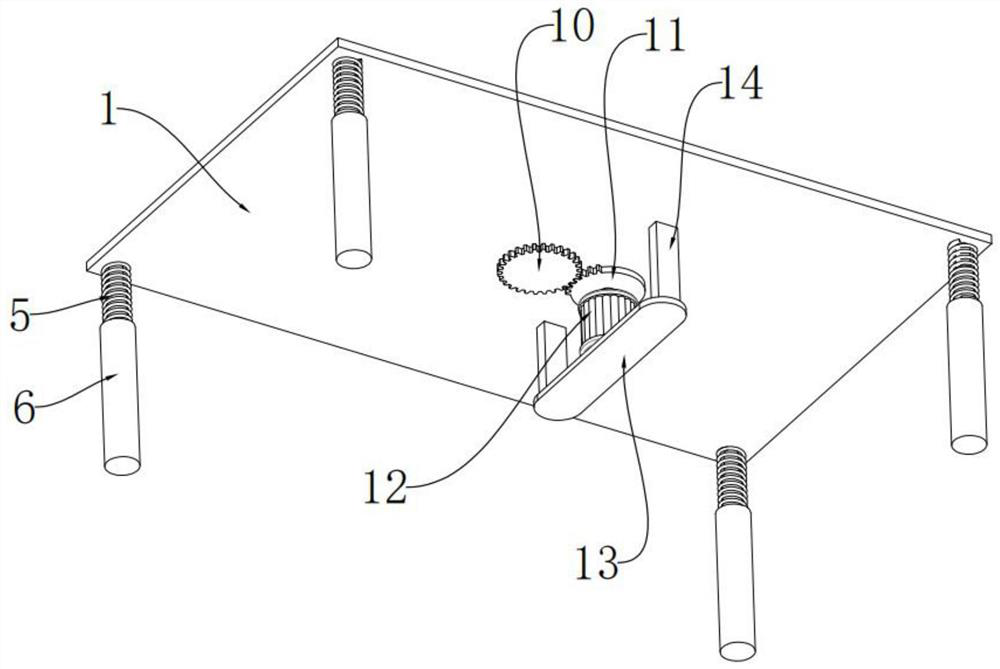

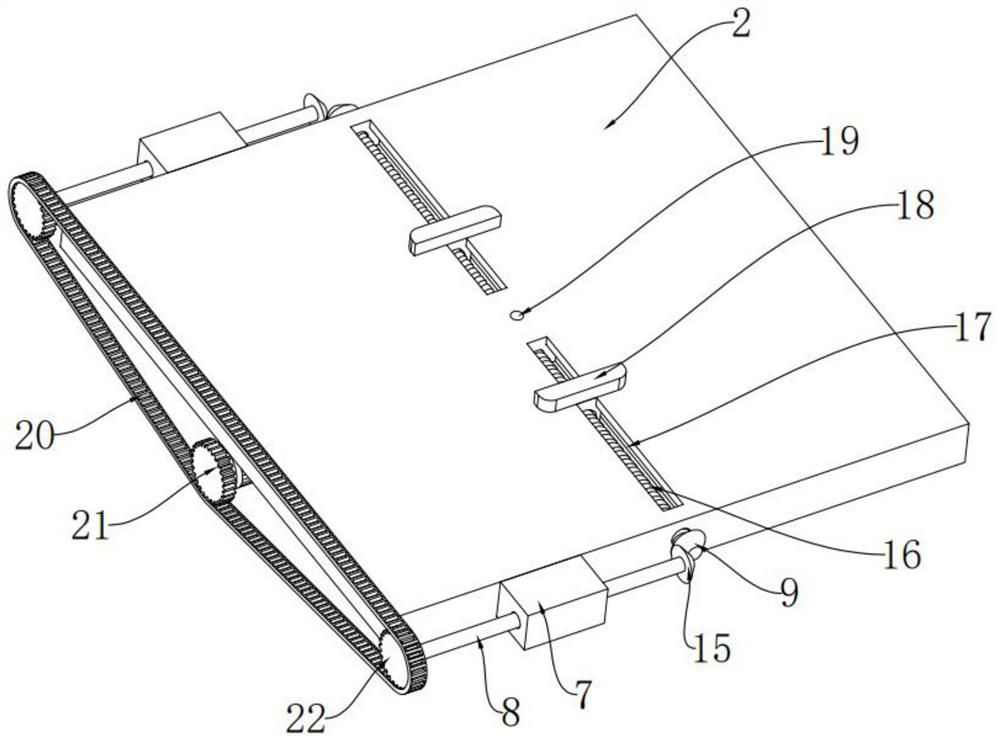

[0041] see Figure 1-10 , the technical solution provided by this embodiment is as follows:

[0042] An assembly device for a carbon brush holder for an automobile, comprising a mounting table 1, two first mounting blocks 4 are fixedly connected to the upper end of the mounting table 1, and a second mounting plate 3 is fixedly connected to the upper ends of the two first mounting blocks 4, The upper side of mounting table 1 is provided with first mounting plate 2, and first mounting plate 2 is positioned between two first mounting blocks 4, and the upper side of first mounting plate 2 is provided with the 4th mounting plate 26, and the 4th mounting plate 26 is located between the two first mounting blocks 4, the lower end of the mounting table 1 is fixedly connected with two third mounting blocks 14, the lower ends of the two third mounting blocks 14 are fixedly connected with a third mounting plate 13, the second mounting plate The lower end of 3 is provided with the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com