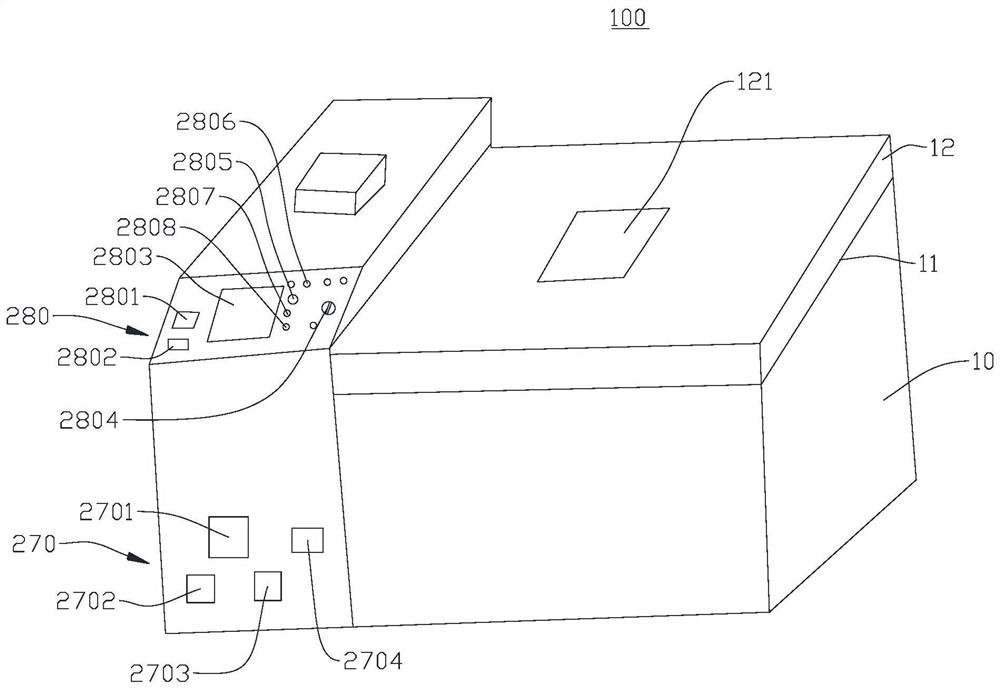

Freeze-thaw test equipment for simulating ultralow temperature-large temperature difference freeze-thaw process of concrete

A kind of test equipment and ultra-low temperature technology, applied in the field of freeze-thaw test, can solve problems such as difficult to simulate extreme environments and differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

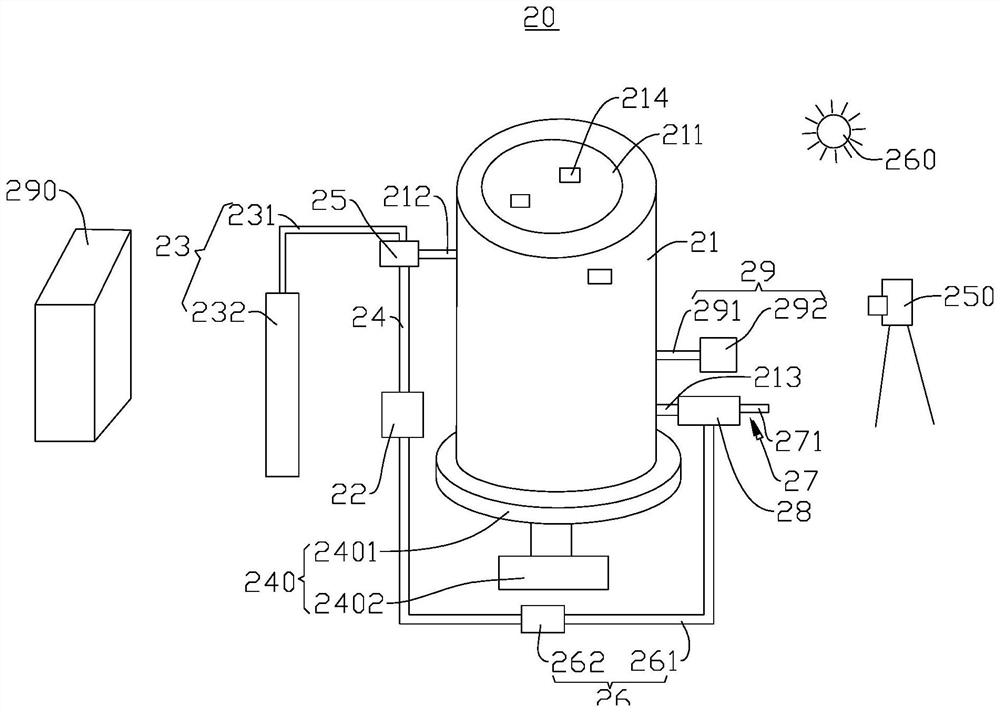

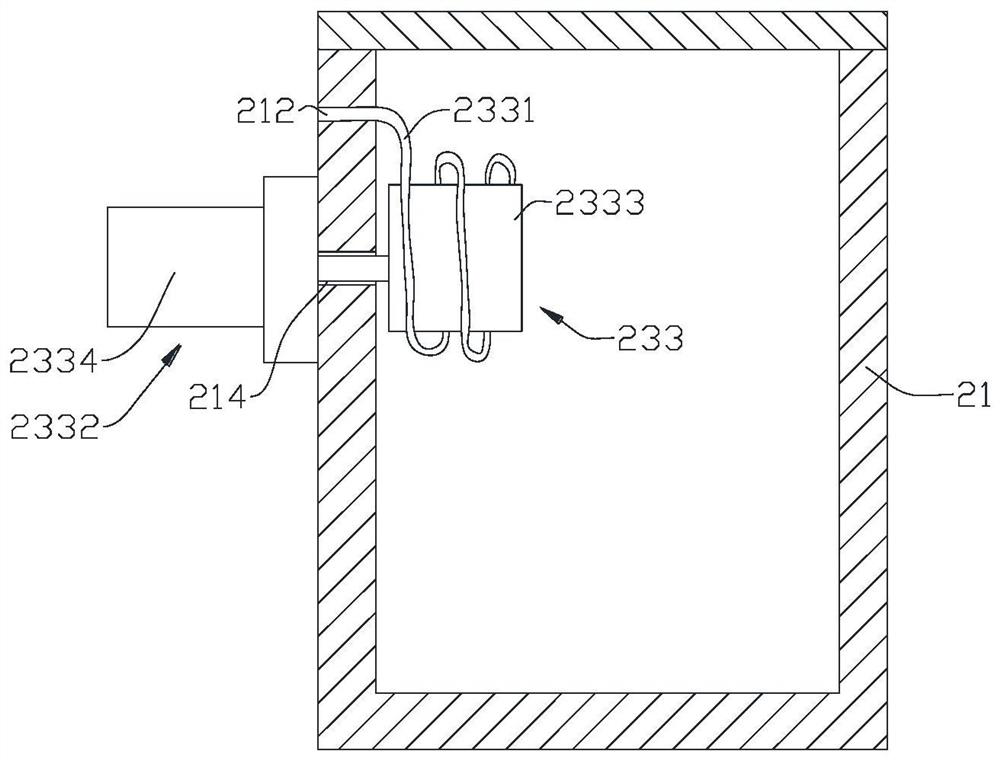

Embodiment

[0039] With the rapid growth of global energy demand for liquefied natural gas, the construction of liquefied natural gas receiving terminals is increasing. The outer tank of the liquefied natural gas storage tank is reinforced concrete. When the liquefied natural gas is stored in the concrete storage tank, the storage temperature in the storage tank is about -165°C, and the outer wall of the storage tank is in contact with the surrounding environment. When natural gas is purified, filled, or even the inner tank leaks, the concrete storage tank will experience a large temperature difference between freezing and thawing, and at the same time, the pressure environment of the concrete storage tank will also undergo drastic changes. This complex effect directly affects the stability of the concrete structure, leading to local deterioration and destruction of the concrete storage tank, and even the leakage of liquefied natural gas in the tank, which leads to a storage tank accident,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com