Preparation method of test sample and test sample

A technology for testing samples and samples, applied in the preparation method of test samples and the field of test samples, can solve the problems of high cost, inability to meet actual needs, low efficiency, etc., and achieve the effects of accurate acquisition, saving sample preparation costs, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] Figure 4 It is a flowchart of a method for preparing a test sample according to an embodiment of the present disclosure. refer to Figure 4 As shown, the method includes the following steps:

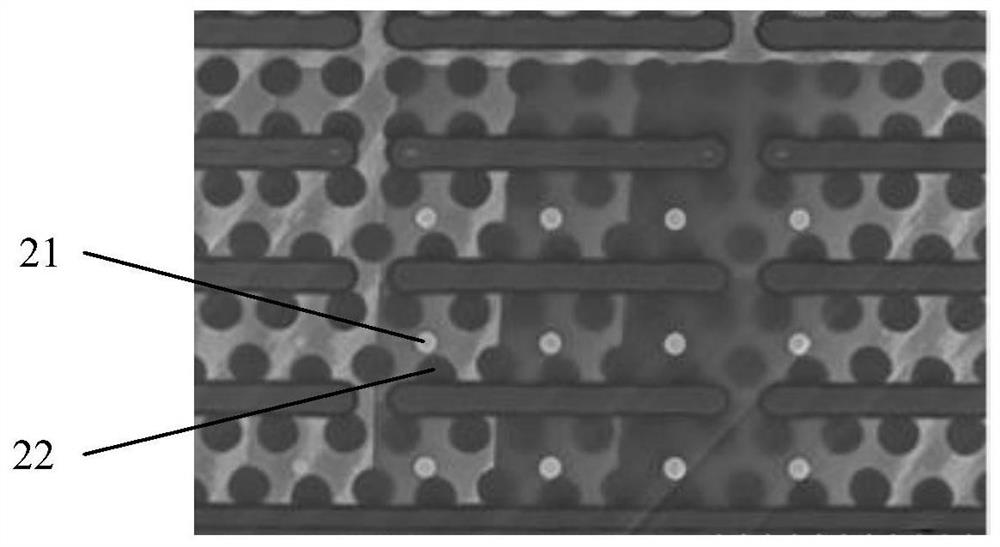

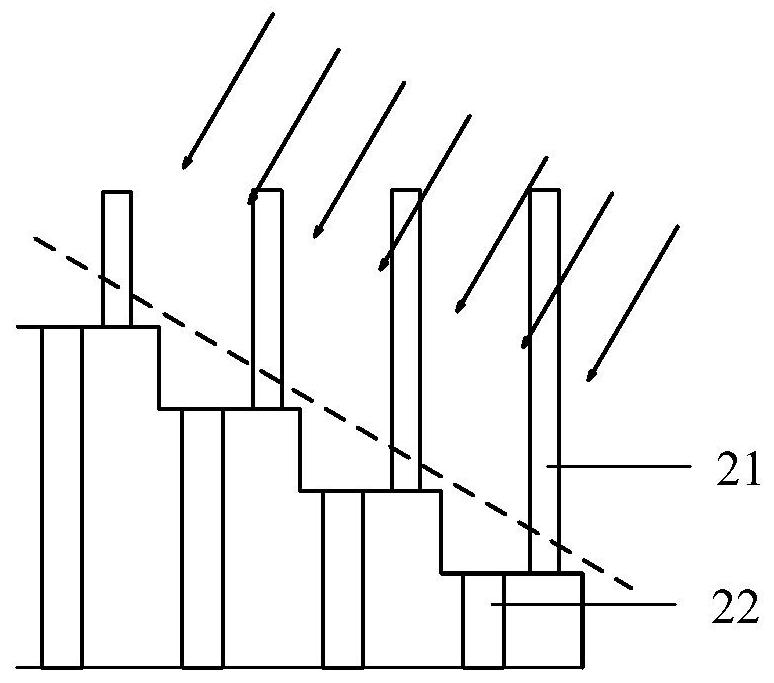

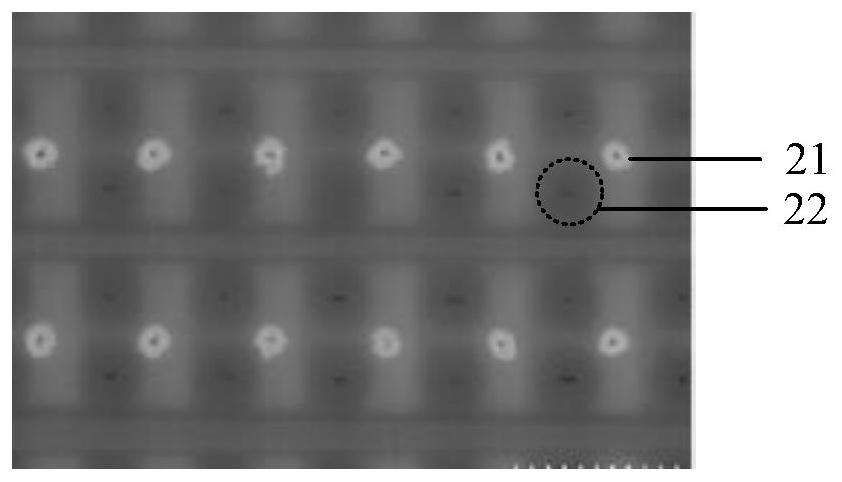

[0066] S100: Provide a structure to be processed including a failure region; wherein, the structure to be processed includes: multi-level steps, a dielectric layer covering the steps, a contact plug located above the surface of the steps and disposed in the dielectric layer, and a dummy channel penetrating through the steps column.

[0067] S110: Thinning the structure to be treated towards the step along the preset direction intersecting the slope where the multi-level steps are located, so as to form a pretreated sample; wherein, the pretreated sample includes the failure area; along the preset direction, the surface of the pretreated sample remains The thickness of the contact plug is greater than or equal to a first preset thickness.

[0068] S120: removing the residual d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com