Cover beam construction auxiliary device and method

An auxiliary device and cover beam technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficult high-altitude construction, hoop slippage accidents, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A detailed description will be given below in conjunction with the accompanying drawings.

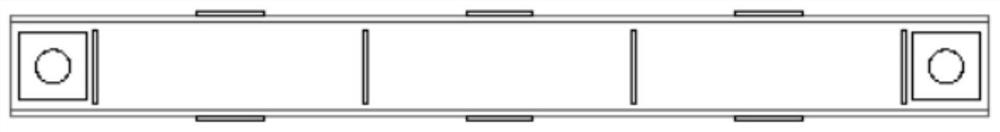

[0041] like figure 1 Shown is a simplified flow chart of the auxiliary method for the construction of the cover beam proposed by the present invention. The auxiliary method for the construction of the cover beam may include pre-construction preparation, installation of the auxiliary support for the cast-in-place cover beam, pouring of the concrete for the cover beam, and demoulding of the concrete for the cover beam. And steps such as dismantling of the cast-in-place cover beam auxiliary support to form a crossbeam located on the top of the pier column 1 and integrated with the pier column 1 .

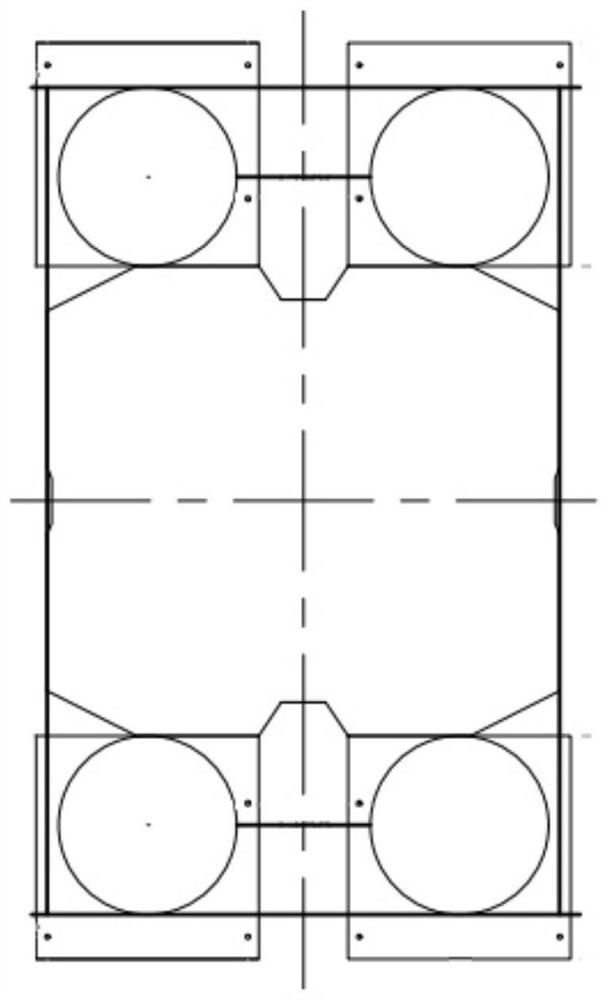

[0042] like Figure 10 As shown, the cover beam includes a cover beam bottom wall 11 , an extension wall 12 , a side wall 13 , a cover beam top surface 14 and a cover beam inner wall surface 15 . The bottom wall 11 of the cover beam extends along the horizontal direction, and is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com