Carbon fiber felt pad weaving and extruding integrated forming machine for aero-engine clamps and method of using the same

An aero-engine and extrusion molding technology, applied in the field of fiber weaving and molding, can solve the problems of large matching size, large space occupation, low weaving efficiency, etc., to avoid insufficient tension, improve product performance, and save processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

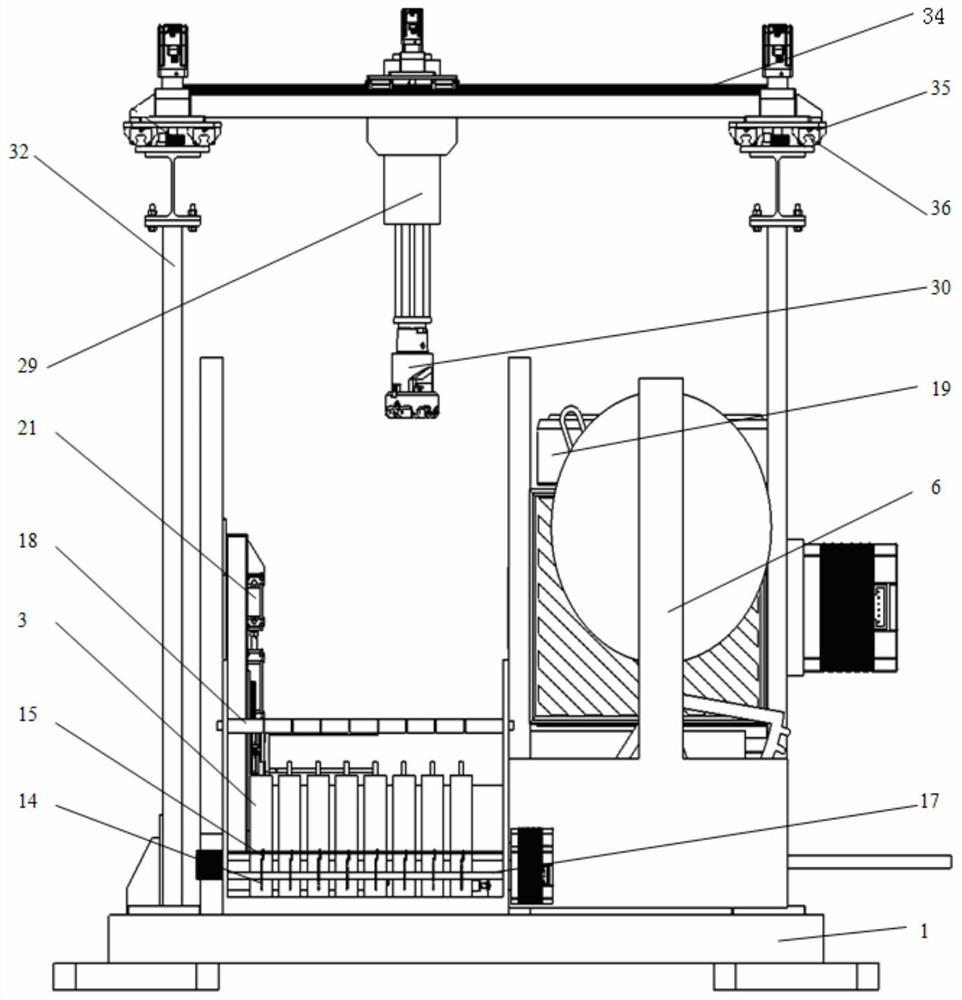

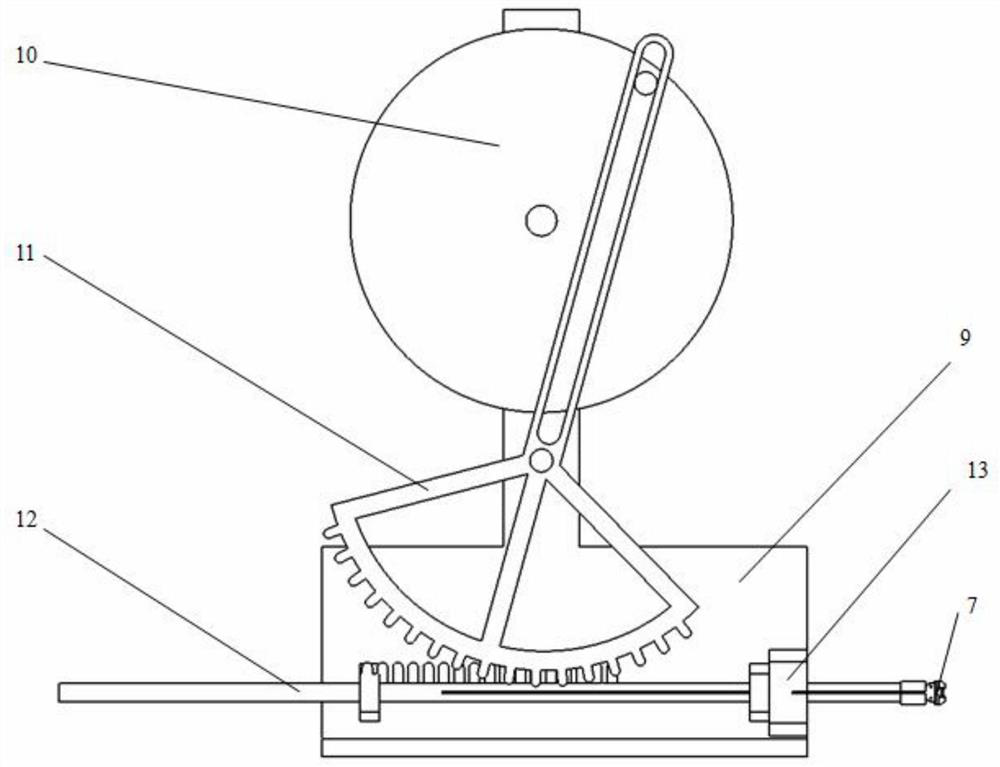

[0044] like Figure 1-7 As shown, the carbon fiber felt pad weaving and extrusion integrated forming machine for aero-engine clamps includes a braiding machine module, an extrusion forming and cutting module and a base 1, and the braiding machine module and the extrusion forming and cutting module are fixedly installed in the On the base 1, the weaving machine module is used for the weaving of the carbon fiber mat, and the extrusion molding and cutting module is used for the extrusion molding and cutting of the carbon fiber mat.

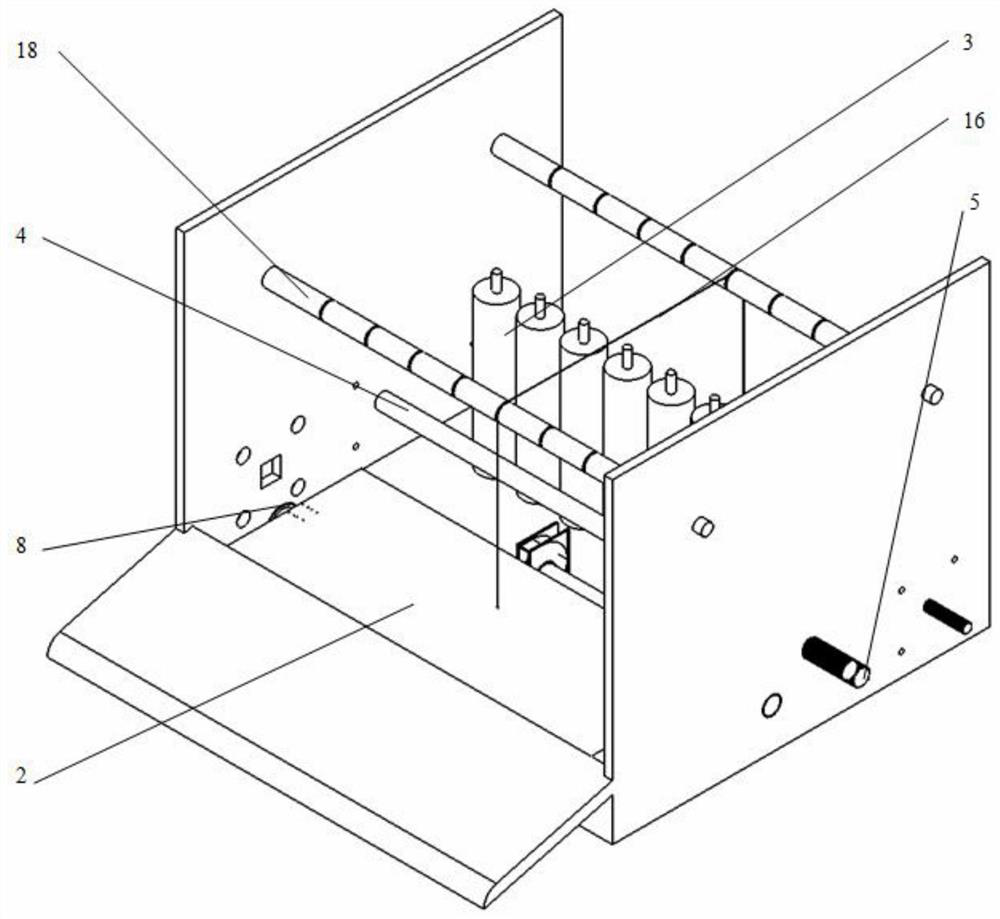

[0045] The braiding machine module includes a warp wire supply structure, a weft wire supply structure, a heald weaving structure and a body 2;

[0046] The body 2 includes a bottom plate, two side walls, a plurality of long rods and a discharge plate. The bottom plate is fixedly mounted on the base 1, and the two side walls are symmetrically and vertically mounted on both sides of the bottom plate. The long rods are fixedly installed on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com