Blockage removing acid solution for removing blockage of high-temperature and high-pressure gas well shaft

An acid solution and plugging removal technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of large formation damage, difficult dredging operation of coiled tubing, and corroded tubing, etc., to achieve small corrosion and strong industry Maximize the application value and the effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

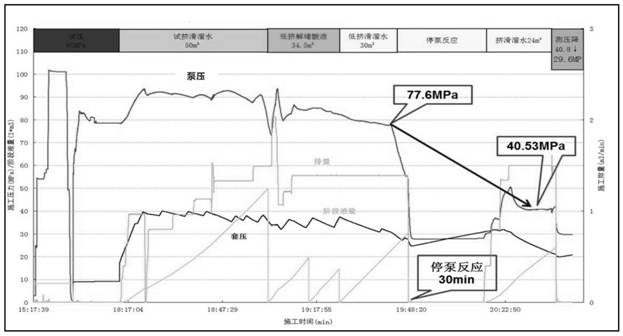

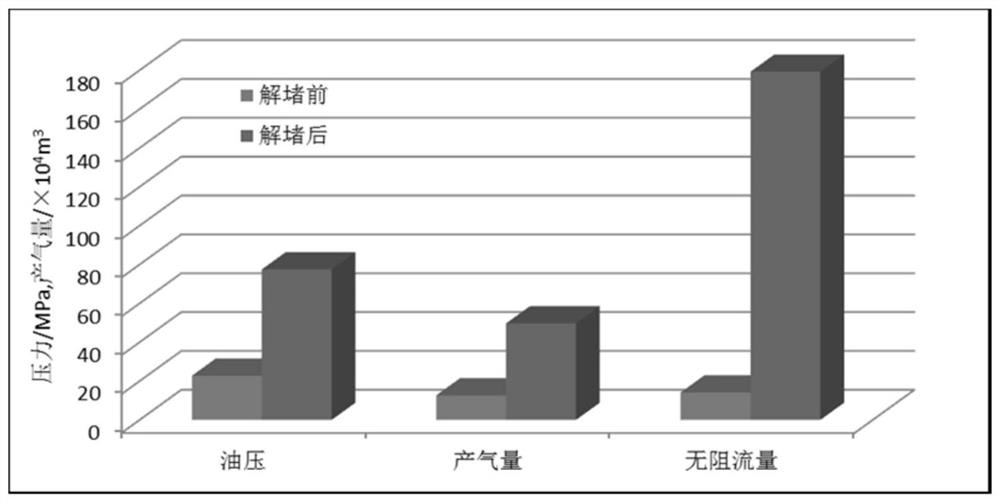

[0052] A well is a production Gas, depth of 7116m, the original formation pressure 123 MPa, bottom temperature 170 ℃. The initial oil production well 97.69MPa, Nissan gas 78.01 × 10 4 M 3 ; Production process due to the wellbore pressure and clogging declining yields, plugging off the wellbore before construction of acidizing, the well hydraulic 22.8MPa, Nissan gas 12.70 × 10 4 M 3 . Take the wellbore plug analysis showed that the main component was blocked for the scum and sand.

[0053] Using an acid of the present invention to resolve the block for plugging acid, acid composition: 9% hydrochloric acid, hydrofluoric acid 1%, 2% clay stabilizer, corrosion inhibitor 5.1% (3.4% + 1.7% main agent adjuvant) , drainage aid 2%, 2% ferric ion stabilizer, 5% methanol, 1% demulsifier. Wherein: said fracturing the clay stabilizer is poly acidified clay stabilizing cationic quaternary ammonium BD1-13, the corrosion inhibitor is acidified with inhibitor cyclohexanone ZX-09, as the drainage a...

Embodiment 2

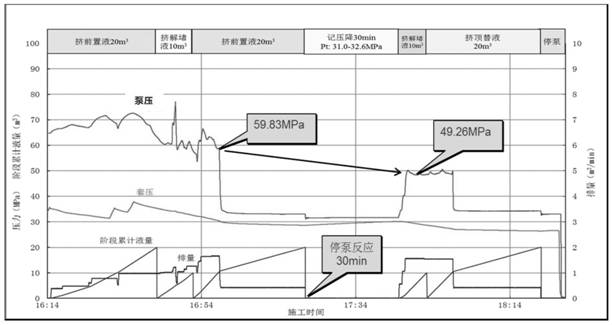

[0059] B is a production Gas wells, depth 5100M, for the screen completion, 105MPa original formation pressure, bottom hole temperature 136 ℃. The initial oil production well 82MPa, Nissan gas 82.81 × 10 4 M 3 ; Production process due to the wellbore pressure and clogging declining yields, plugging off the wellbore before construction of acidizing, the well hydraulic 14.4MPa, Nissan gas 31.27 × 10 4 M 3 . Take the wellbore plug analysis showed that the main component was blocked for the scum and sand.

[0060]For the above B well, the acidified solution of the acidified solution of the present invention is displaced. The specific composition of the chromatic acid solution is: 9% hydrochloric acid, 1% hydrofluoric acid, 2% clay stabilizer, 4.5% corrosion inhibitor (3.0% main agent, 1.5% adjuvant), 2% boost agent, 2% iron ion stabilizer, 5% methanol, 1% demulsifier. Among them: The clay stabilizer is a clay stabilizer quaternary ammonium salt and high polymer XH-F, the corrosion inh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com