Packaging materials, preparation and testing methods for non-destructive testing of agricultural products and food quality

A technology for packaging materials and food quality, applied in chemical instruments and methods, packaging, wrapping paper, etc., can solve the problems of inability to detect spectral detection, without considering spectral detection, etc., to improve detection sensitivity, easy and fast operation, and meet the needs of rapid detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Fabrication of flexible base layer;

[0063] Take the flat quartz wafer or silicon wafer and put it in acetone, ethanol and water for ultrasonic cleaning for 5 minutes each. After drying it, spin-coat polydimethylsiloxane on the surface and heat it to cure. The polydimethylsiloxane is used as the flexible base. bottom layer;

[0064] (2) the production of adhesive layer;

[0065] Spin-coat polyimide on the surface of the flexible substrate and heat it to cure, polyimide is used as an adhesive for bonding packaging and transparent conductive layers;

[0066] (3) the production of transparent conductive layer;

[0067] On the polyimide, 200 nm of indium tin oxide was vapor-deposited as a transparent conductive layer.

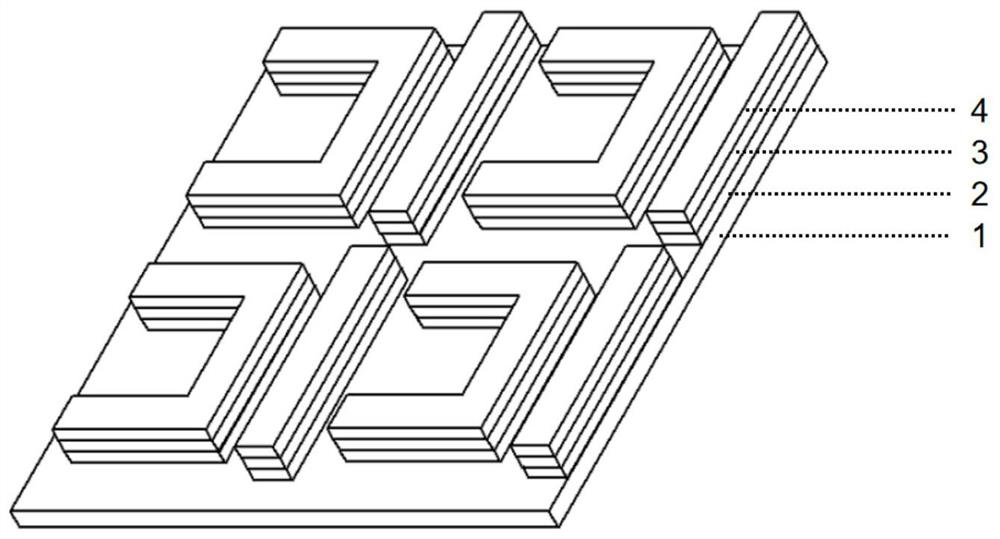

[0068] (4) Fabrication of nanostructured layer;

[0069] Firstly, 43nm nano-silver squares were synthesized; 0.1 mg / mL PEG-SH solution in chloroform was prepared; the nano-silver squares solution, PEG-SH chloroform solution and methanol solution wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com