Construction operation platform for prefabricating box girder

A working platform and platform technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of inconvenient construction personnel passing up and down, and inconvenient way of prefabricated box girder construction operation platform, so as to achieve high construction efficiency, strong practicability, and platform The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

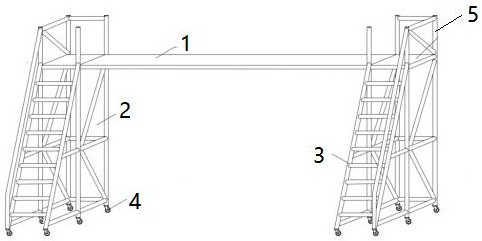

[0024] The construction operation platform for prefabricated box girder of the present invention includes a platform body and two supporting units.

[0025] see now figure 1 , figure 1 It is a structural schematic diagram of the construction work platform of the embodiment of the present invention. As shown in the figure, the platform body includes a steel pipe frame 8 and a grid steel plate 7. The steel pipe frame is a rectangular steel pipe support, and the rectangular steel pipe support is provided with two parallel steel pipes as long sides. The short steel pipes are provided with diagonal braces between two adjacent short steel pipes to increase the strength of the steel pipe frame. Guardrail 5. figure 2 It is a schematic diagram of the steel pipe frame and the grid steel plate of the platform body of the embodiment of the present invention.

[0026] The two support units each include an upright bracket 2 and a ladder 3, the upright bracket is a well-shaped steel pip...

Embodiment 2

[0030] The manufacture method of the construction work platform for prefabricated box girder of the present invention:

[0031] The structure of the construction work platform for the prefabricated box girder of the present invention is mainly composed of a pulley with a locking function, a work platform, an up and down ladder passage, a support assembly and the like.

[0032] The operation platform is composed of three grid steel plates, the specifications are 3500*1000*4 one piece, 1000*1000*4 two pieces, and the specification is 48.3*3.0 round steel pipe, and the operation platform is welded and formed.

[0033] For the connection of the steel pipe components between the work platforms, the 48.3*30 steel pipes are socketed with 54.3 steel pipe sleeves and fixed with M20 double nuts and bolts. image 3 It is a schematic diagram of connecting steel pipes with different diameters according to the embodiment of the present invention.

[0034] The upper and lower ladder passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com