Carbon-carbon composite material production equipment and production process thereof

A carbon composite material and production equipment technology, which is applied in the field of carbon-carbon composite material production and processing, can solve the problems of inconvenient and fast dust removal, and achieve the effects of simple structure, convenient use, and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

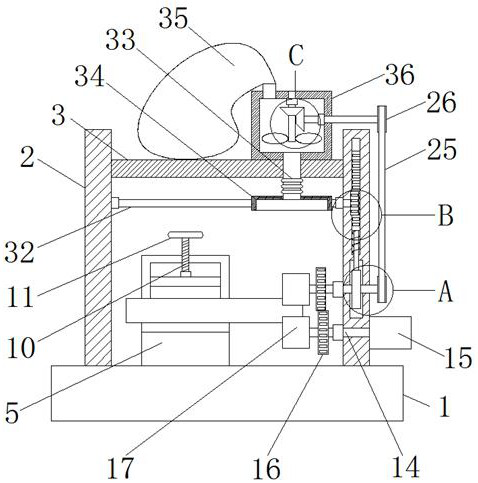

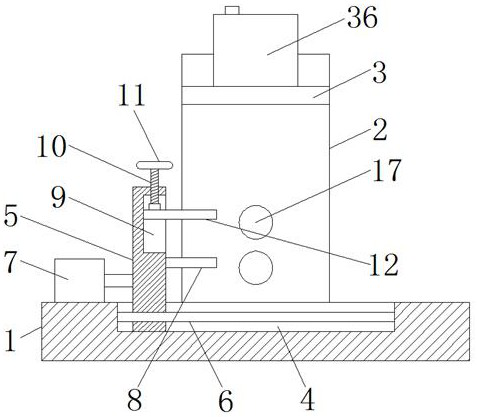

[0033] refer to Figure 1-5 , carbon-carbon composite material production equipment, including a base 1, two symmetrical vertical plates 2 are fixedly installed on the top of the base 1, the outer sides of the two vertical plates 2 are fixedly connected with the same mounting plate 3, and the top of the base 1 is provided with The first chute 4, the first chute 4 is provided with a positioning mechanism, the top of the mounting plate 3 is fixedly installed with a bellows 36, the bottom of the bellows 36 is provided with a mounting hole, and the bellows 33 is fixedly installed in the mounting hole, the bellows 33 One end of the bellows 36 is fixedly connected with a dust collection cover 34, the top of the bellows 36 is provided with an air outlet, and the outside of the air outlet is fixedly connected with a dust-proof cloth bag 35, and a dust removal mechanism is arranged in the bellows 36, and an empty slot 13 is provided in the vertical plate 2. Two first through holes are ...

Embodiment 2

[0043] refer to Figure 1-5 , carbon-carbon composite material production equipment, including a base 1, the top of the base 1 is fixedly installed with two symmetrical vertical plates 2 by welding, and the outer sides of the two vertical plates 2 are fixedly connected with the same mounting plate 3 by welding, the base 1 There is a first chute 4 on the top of the chute, and a positioning mechanism is arranged in the first chute 4. The top of the mounting plate 3 is fixedly installed with a bellows 36 by welding, and the bottom of the bellows 36 is provided with a mounting hole, and the mounting hole is fixed and installed by welding. There is a bellows 33, one end of the bellows 33 is welded and connected to a vacuum cover 34, the top of the bellows 36 is provided with an air outlet, the outside of the air outlet is connected to a dustproof bag 35 by bolts, and the bellows 36 is provided with a dust removal mechanism , the riser 2 is provided with an empty slot 13, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com