Method for replacing slewing bearing of ladle turret

A technology of bale turntable and slewing bearing, which is applied in metal processing, metal processing equipment, hand-held tools, etc. It can solve the problems of high risk of jacking, arrangement on the edge of the corner, and increased difficulty of jacking, so as to shorten the operation time, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

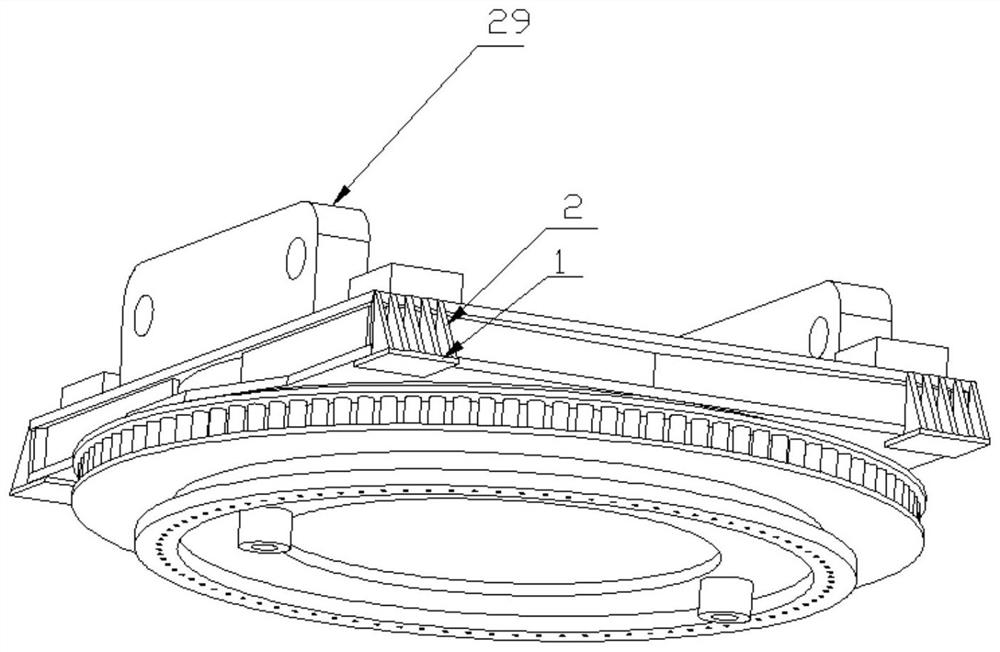

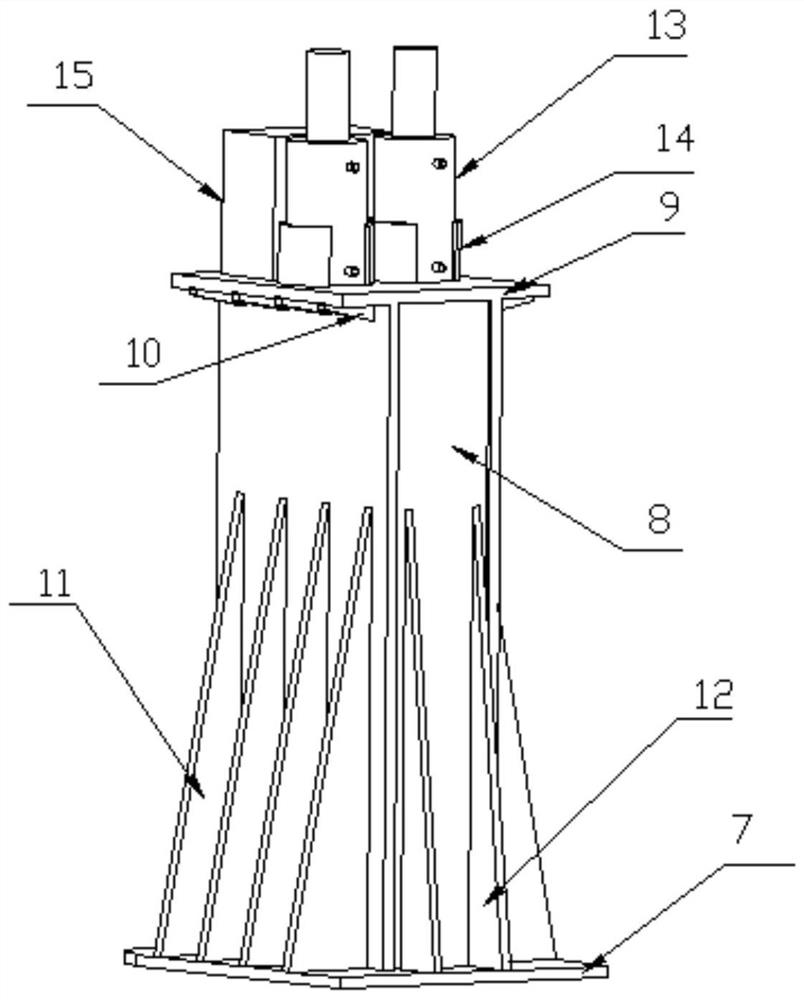

[0021] Embodiment 1: see figure 1 , a method for replacing a slewing bearing of a bale turntable, the method is as follows:

[0022] Step 1: In order to increase the working area for jacking, weld a 600*600*40 steel plate on the four corners of the turntable as the jacking extension surface 1, and weld 5 pieces of 50 thick right angles on the working surface extending 300*600 Rib plate 2; the lifting arm of the turntable is turned to the east-west direction, and the bearing is removed from the south face and hoisted away with a pouring straddle truck. In order to facilitate the on-site positioning of the oil cylinder support seat, four support seat positioning plates (3, 4, 5, 6) with a thickness of 40mm are installed on the continuous casting platform in advance. The positioning plates are symmetrically arranged on the vertical and horizontal centerline of the rotary body. The positioning dimensions are shown in the figure below ( figure 2 ), the on-site rapid positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com