Sugar-coated haw string type antibacterial and antiviral filter screen and manufacturing process thereof

A production process and filter screen technology, applied in filtration separation, membrane filter, biochemical fiber treatment and other directions, can solve the problems of high cost of silver ions, poor antibacterial effect of natural antibacterial agents, insufficient cost and dosage, etc., and achieve long-term effective use. Cost, maintaining photocatalytic activity, excellent antibacterial and antiviral effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

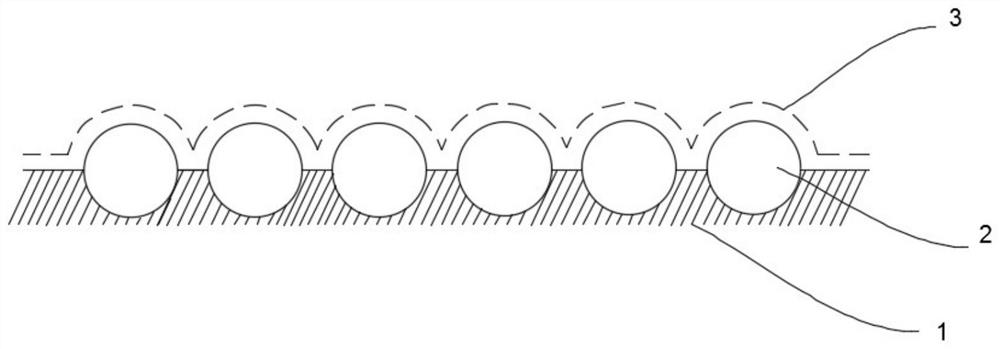

[0028] Such as figure 1 As shown, the invention discloses a candied haws string type antibacterial and antiviral filter screen and its manufacturing process.

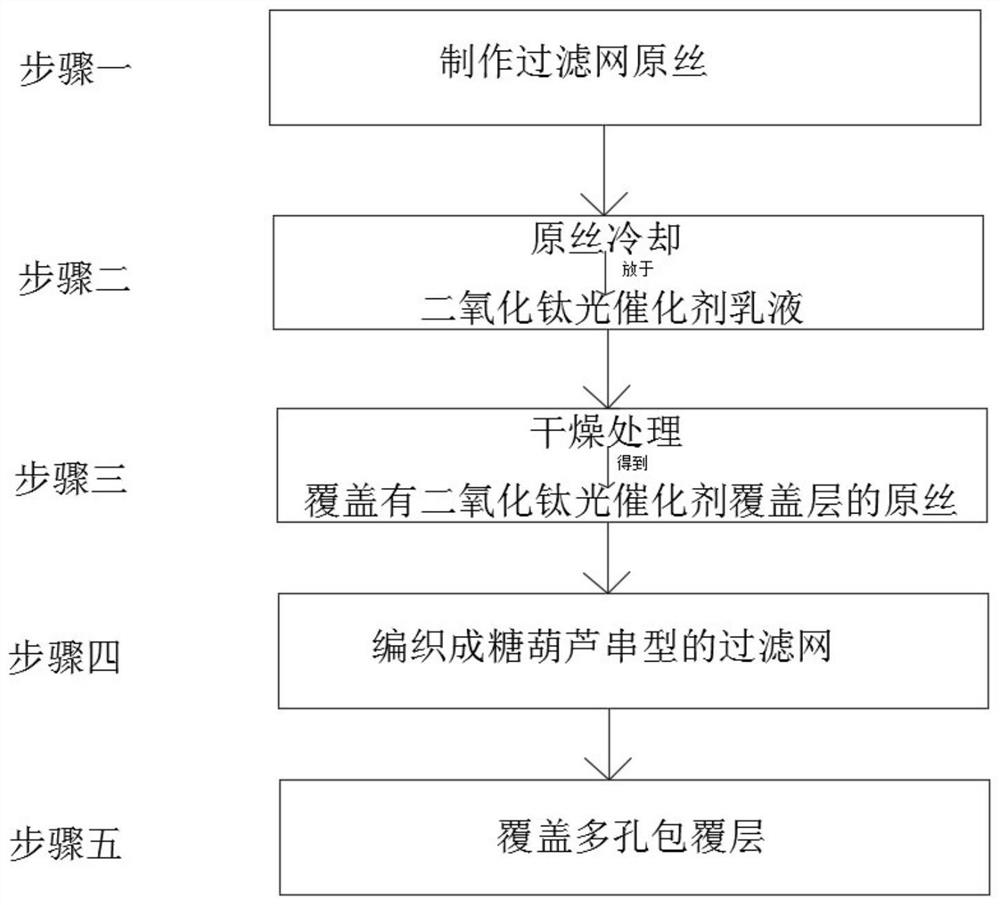

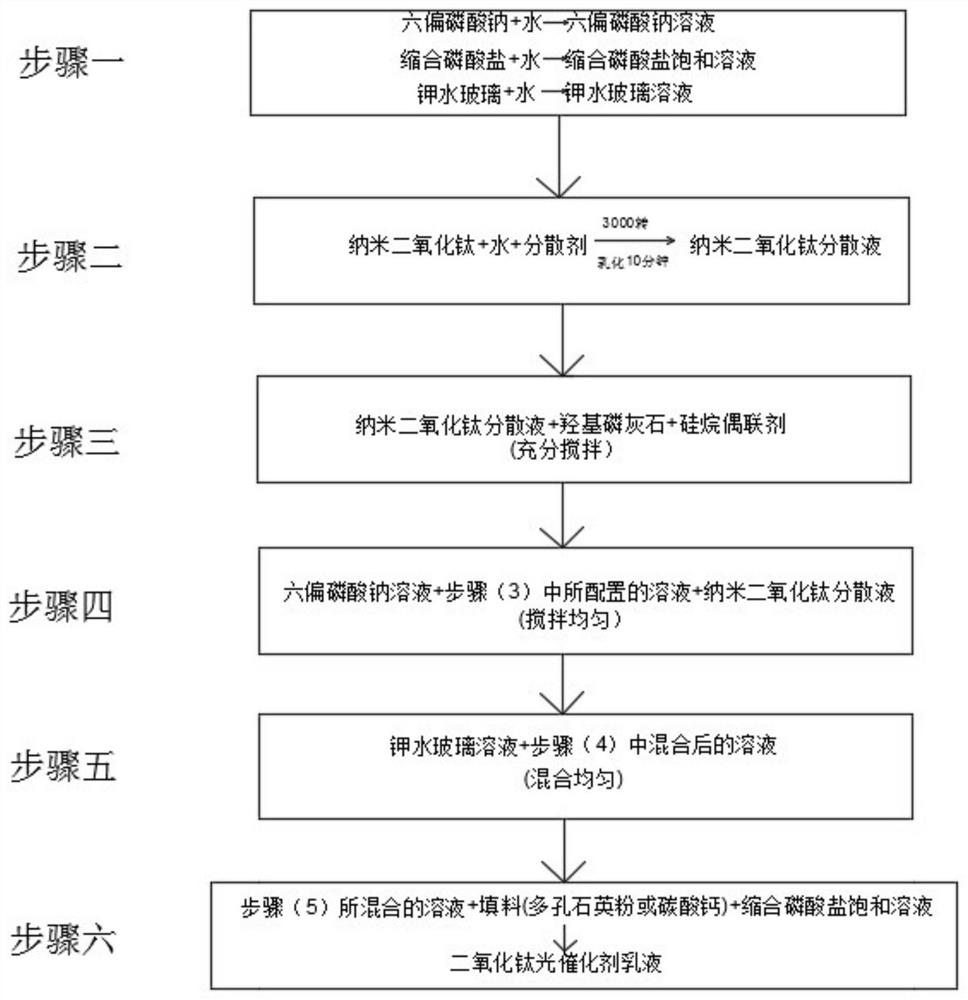

[0029] A candied haws string type antibacterial and antiviral filter screen and its production process include raw silk, titanium dioxide photocatalyst covering layer and porous coating layer. The specific production process is as follows:

[0030] (1) make the precursor of this filter screen, soak in the titanium dioxide photocatalyst emulsion when the precursor is cooling, thereby obtain the precursor that the surface is covered with titanium dioxide photocatalyst emulsion;

[0031] (2) drying, the precursor silk that surface is covered with titanium dioxide photocatalyst emulsion in step (1) is carried out drying treatment, thereby obtains the precursor silk that surface is covered with titanium dioxide photocatalyst covering layer;

[0032] (3) weaving into a net, the raw silk that the surface obtained after the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com