Fire-fighting water anti-freezing device for fire-fighting

An antifreeze device and fire water technology, which is applied in lighting and heating equipment, heat storage heaters, fluid heaters, etc., can solve the problems of easy freezing of fire water tank water, inability to pump out fire water tank water, and affecting the normal use of fire water tanks, etc. , to achieve the effect of preventing water temperature drop and snow accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

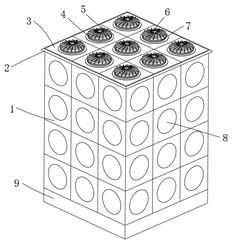

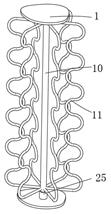

[0029] refer to Figure 1-5 , a fire-fighting water antifreeze device for fire-fighting, comprising a water tank body 1, the bottom outer wall of the water tank body 1 is fixedly connected with a base 9, and the top outer wall of the water tank body 1 is fixedly connected with a top shell 3, and the top inner wall of the top shell 3 There is a wind guide gap between the top outer wall of the water tank body 1, and at least one evenly distributed antifreeze mechanism is arranged inside the water tank body 1. The antifreeze mechanism includes a rotating shaft 10, and the side outer wall of the rotating shaft 10 is fixedly connected with at least three An annular ring 11 evenly distributed in the ring, the annular ring 11 is a wavy annular rod-shaped structure, the top of the rotating shaft 10 extends above the top case 3, the rotating shaft 10 and the top case 3 can slide and rotate relative to each other, and the top of the rotating shaft 10 is fixed An arc-shaped disc 4 is con...

Embodiment 2

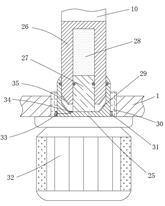

[0036] refer to Image 6 with Figure 7 , a fire-fighting water antifreeze device for fire-fighting. Compared with Embodiment 1, the outer wall of the side surface of the rotating shaft 10 above the top shell 3 is fixedly connected with an upper pressing block 22, and the top shell 3 is located on the top below the upper pressing block 22. The outer wall is fixedly connected with an upper fixing seat 20, the top outer wall of the upper fixing seat 20 is rotatably connected with a fan seat 21, the side outer wall of the fan seat 21 is fixedly connected with a fan blade 24, the top outer wall of the fan seat 21 and the bottom outer wall of the upper pressing block 22 Matching engagement grooves are provided, and the top outer wall of the top shell 3 located below the fan blade 24 is provided with a lower air guide groove 23, and the edge of the bottom outer wall of the arc-shaped disk 4 is rotatably connected with an outer protective shell 6, and the outer protective shell 6 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com