A kind of squeeze type threshing separation device and harvester

A threshing separation and drum technology, which is used in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of high crop looseness, large grain impact, poor squeezing effect, etc., so as to increase squeezing capacity and reduce breakage rate. , Improve the effect of threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

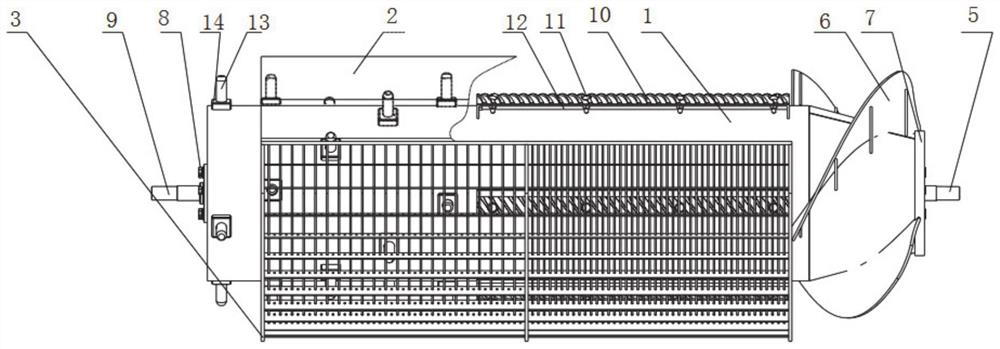

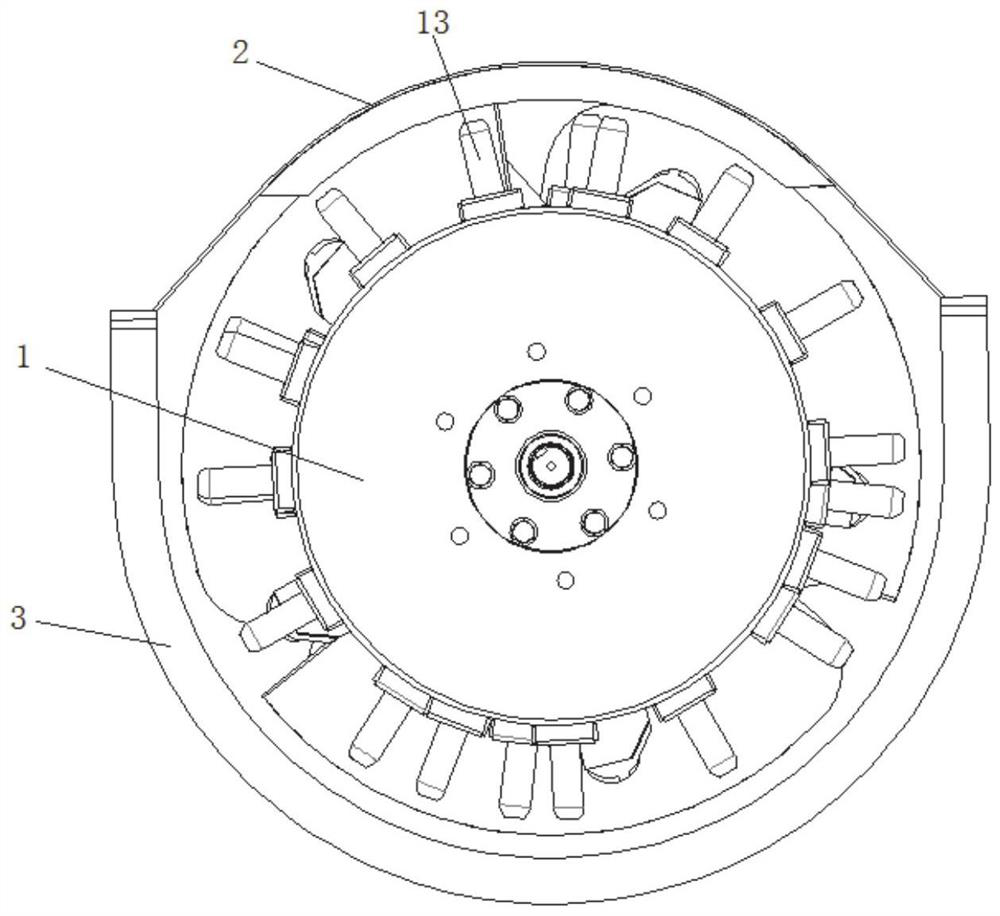

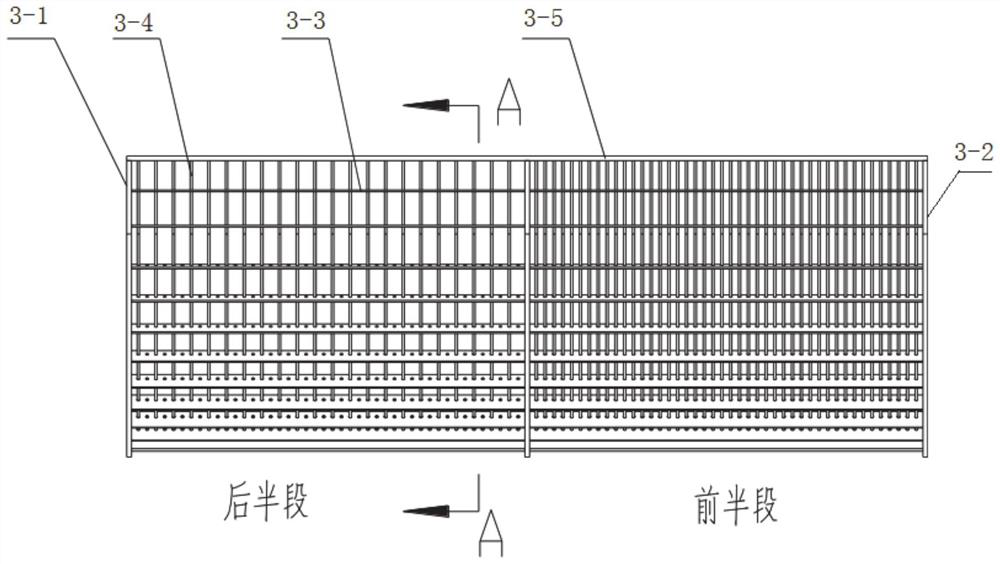

[0030] This embodiment discloses a squeezing and rubbing type threshing and separating device, such as Figure 1-Figure 2 As shown, it includes a drum 1, the drum can be rotated, a top cover 2 is arranged above the drum, the top cover is fixedly arranged, and can be fixed on a corresponding frame body, and a grid member 3 is provided below the drum, and the grid member is fixedly arranged , which can be fixed on the corresponding frame body, the top cover and the grid member are arc-shaped structures, and after the top cover and the grid member are combined, they can wrap the peripheral space of the drum.

[0031] In another embodiment, both ends of the top cover are provided with fixing plates, and the top cover is fixedly connected to the grid member through the fixing plates.

[0032] The two ends of the drum are the feeding end and the discharging end, respectively. The feeding end of the drum is connected with a feeding part 4. The feeding part adopts a truncated cone-sha...

Embodiment 2

[0052] This embodiment discloses a harvester, which is installed with the squeezing type threshing and separating device described in Embodiment 1, and the drum is connected to a drive mechanism installed on the harvester frame through a first shaft head or a second shaft head , the driving mechanism can be a diesel engine, the diesel engine is connected with the first axle head or the second axle head through a transmission mechanism, and the transmission mechanism can be a chain transmission mechanism or a belt transmission mechanism.

[0053] The top cover and the grid member are both fixed on the frame of the harvester. In order to facilitate the collection of grains, a collection box is arranged below the grid member, and the collection box is fixed on the frame of the harvester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com