Red mud and acidic electrolytic manganese residue synergistic soil treatment and land reclamation method

A technology of acidic electrolysis and land reclamation, which is applied in the fields of soil preparation, leguminous plant cultivation, cultivation, etc., can solve the problems such as threats to the surrounding environment, and achieve the effects of reducing bulk solid waste, accelerating soil transformation, and increasing fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

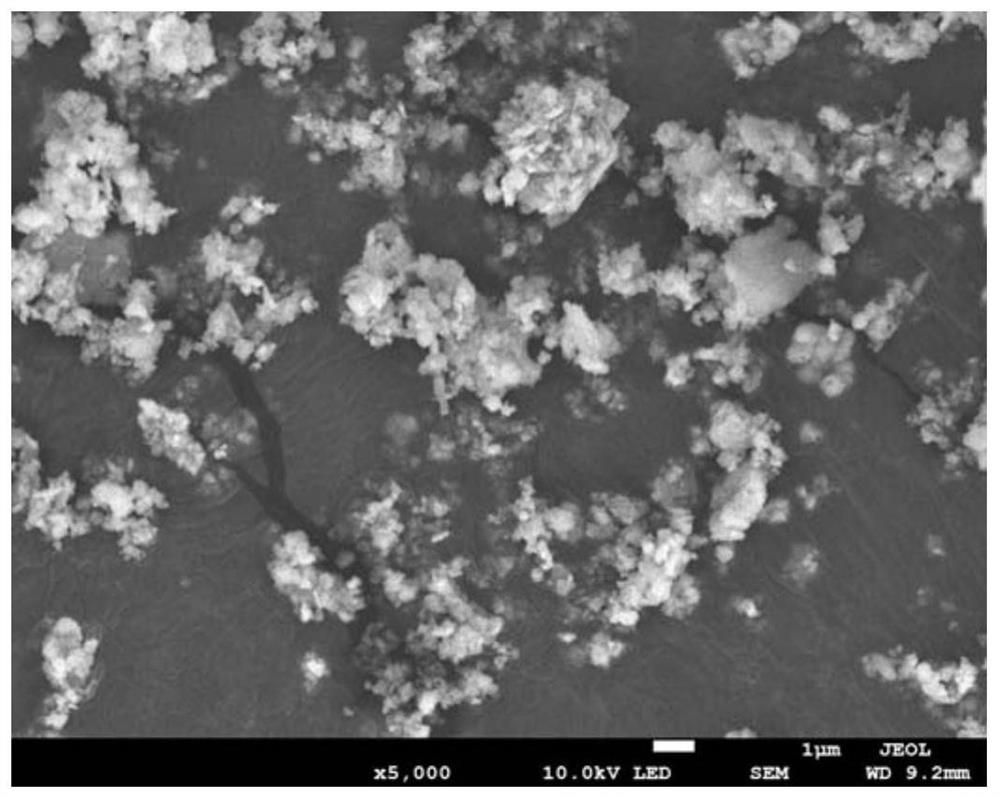

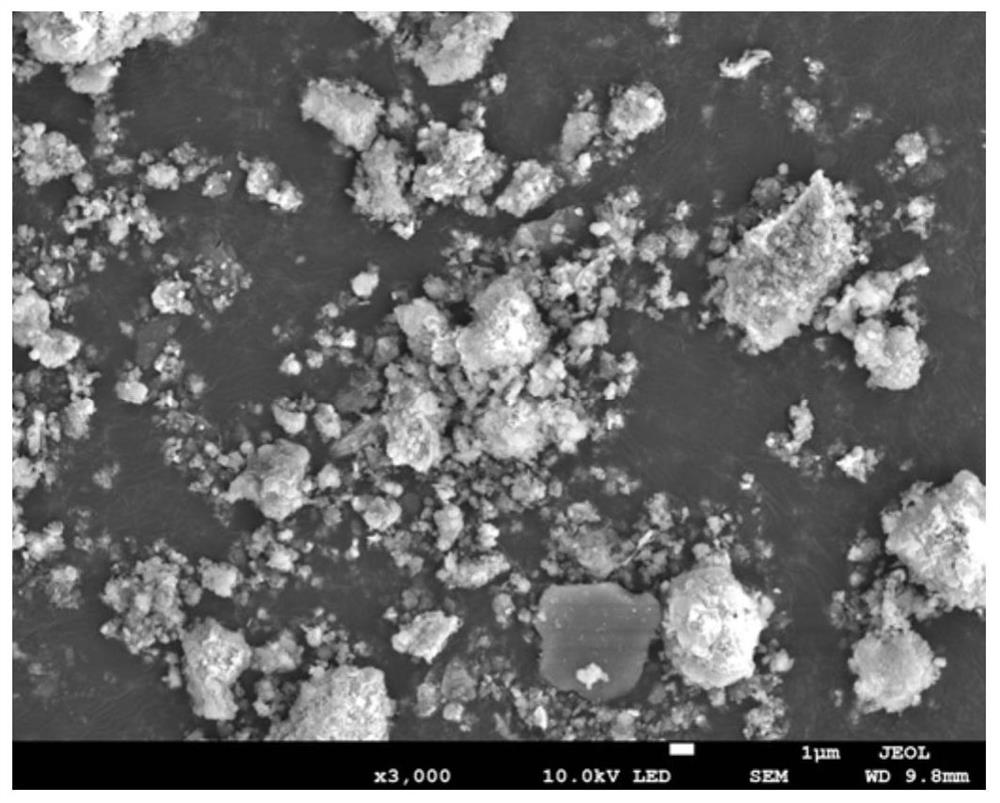

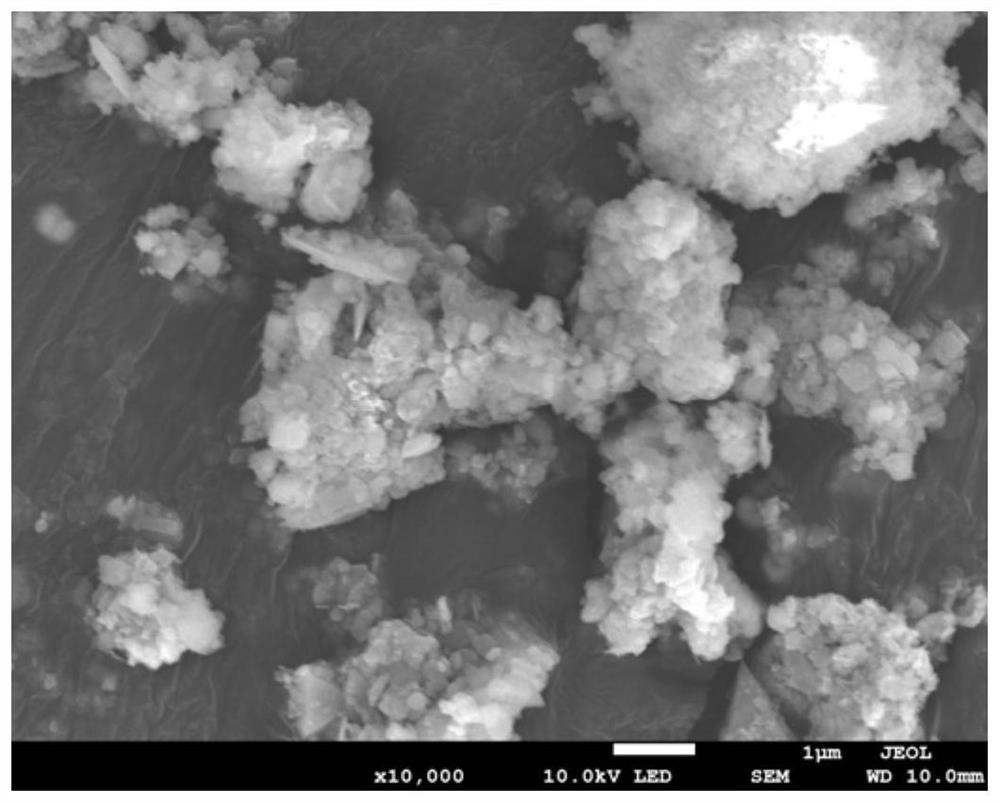

Image

Examples

Embodiment 1

[0032] A method for collaborative soil treatment and land reclamation of red mud and acidic electrolytic manganese slag, comprising the following steps:

[0033] (1) Mixed stacking: collect and mix the red mud obtained after the bauxite ore mining and processing and the electrolytic manganese slag obtained after the manganese carbonate ore mining and processing, and stack them for an appropriate time. The pile is turned by an excavator, wherein the mass fraction of red mud is 30 parts, and the mass fraction of the electrolytic manganese slag is 60 parts. During the stacking period, the temperature is continuously above 28°C and the precipitation is less than 10mm in summer or autumn. , sprinkle water according to 2% of the volume of electrolytic manganese slag during the turning process; the time of mixing and stacking is 15 days, the number of times of turning is 2 times, and the total time of turning is 15 days;

[0034] (2) Wet and dry alternately: spread the mixed red mud ...

Embodiment 2

[0039] A method for collaborative soil treatment and land reclamation of red mud and acidic electrolytic manganese slag, comprising the following steps:

[0040] (1) Mixed stacking: after the red mud obtained after the mining and processing of the bauxite ore and the electrolytic manganese slag obtained after the mining and processing of the manganese carbonate ore are collected, mixed and stacked for an appropriate time, the pile is turned and mixed at intervals, wherein The mass fraction of the red mud is 55 parts, and the mass fraction of the electrolytic manganese slag is 35 parts. The excavator is used to turn the pile. During the stacking period, the temperature is continuously above 28°C and the precipitation is less than 10mm in summer or autumn. , sprinkle water according to 4% of the volume of electrolytic manganese slag during the turning process; the time of mixing and stacking is 30 days, the number of times of turning is 5 times, and the total time of turning is 3...

Embodiment 3

[0046] A method for collaborative soil treatment and land reclamation of red mud and acidic electrolytic manganese slag, comprising the following steps:

[0047] (1) Mixed stacking: collect and mix the red mud obtained after the bauxite ore mining and processing and the electrolytic manganese slag obtained after the manganese carbonate ore mining and processing, and stack them for an appropriate time. The pile is turned by an excavator, wherein the mass fraction of red mud is 45 parts, and the mass fraction of the electrolytic manganese slag is 45 parts. During the stacking period, the temperature is continuously above 28°C and the precipitation is less than 10mm in summer or autumn. , sprinkle water according to 3% of the volume of electrolytic manganese slag during the turning process; the time of mixing and stacking is 20 days, the number of times of turning is 3 times, and the total time of turning is 20 days;

[0048] (2) Wet and dry alternately: spread the mixed red mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com