Preparation method of integrated semiconductor device and integrated semiconductor device

A semiconductor and integrated technology, applied in the field of semiconductor manufacturing, can solve the problems of metal bonding scheme device damage, limited integration density, wafer warpage, etc., achieve convenient series-parallel scheme, increase process window, and small via size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

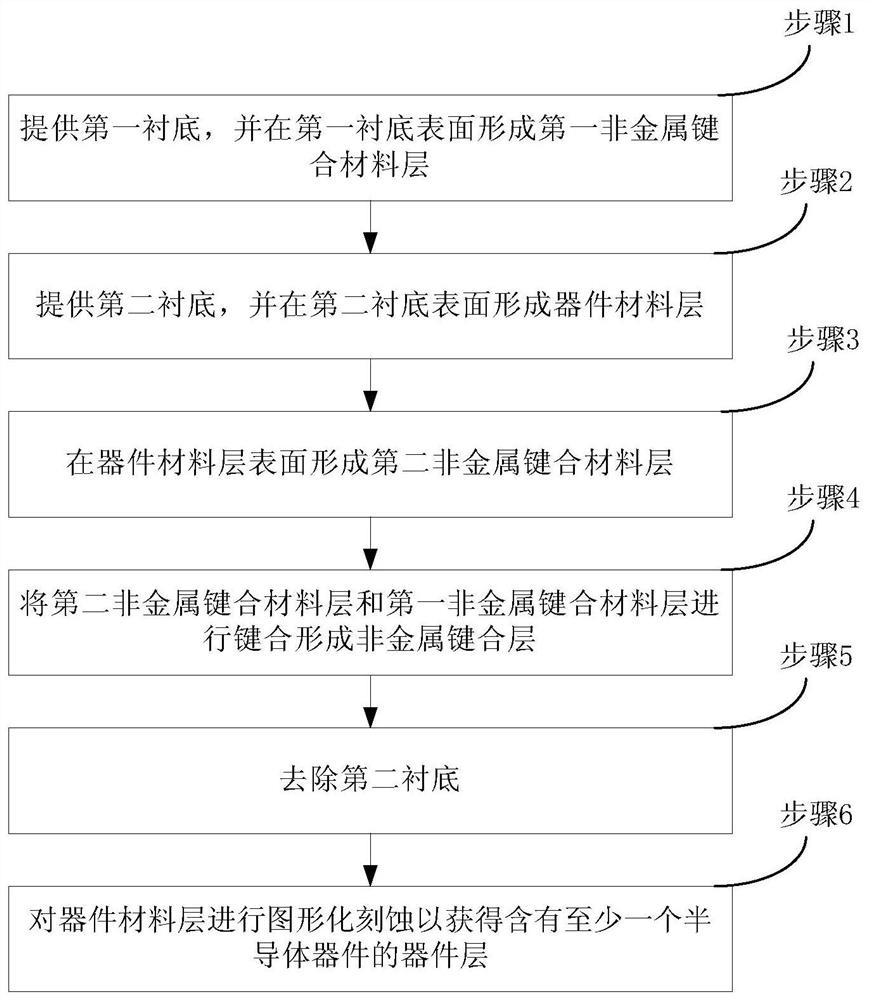

[0077] Such as figure 1 As shown, the embodiment of the present invention provides a method for manufacturing an integrated semiconductor device, which mainly includes the following steps:

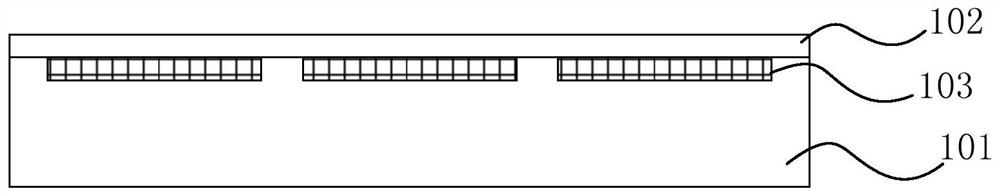

[0078] Step 1, providing a first substrate, and forming a first non-metallic bonding material layer on the surface of the first substrate;

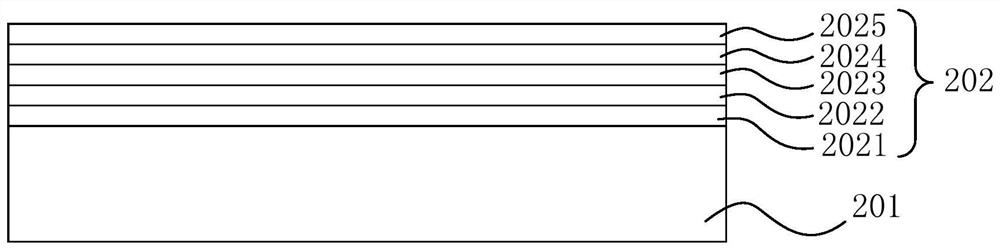

[0079] Step 2, providing a second substrate, and forming a device material layer on the surface of the second substrate;

[0080] Step 3, forming a second non-metallic bonding material layer on the surface of the device material layer;

[0081] Step 4, bonding the second non-metallic bonding material layer and the first non-metallic bonding material layer to form a non-metallic bonding layer;

[0082] Step 5, removing the second substrate;

[0083] Step 6, performing patterned etching on the device material layer to obtain a device layer containing at least one semiconductor device.

[0084] In an optional embodiment, the material of the first sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com