Production process of foaming core wire of coaxial cable with excellent performance

A coaxial cable and core wire technology, applied in the manufacture of coaxial cables, cable/conductor manufacturing, conductor/cable insulation, etc., can solve the problems of affecting the conductor wire diameter, increasing the echo performance, and poor echo, etc., to achieve Guaranteed consistency, stable wire tension, and the effect of eliminating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

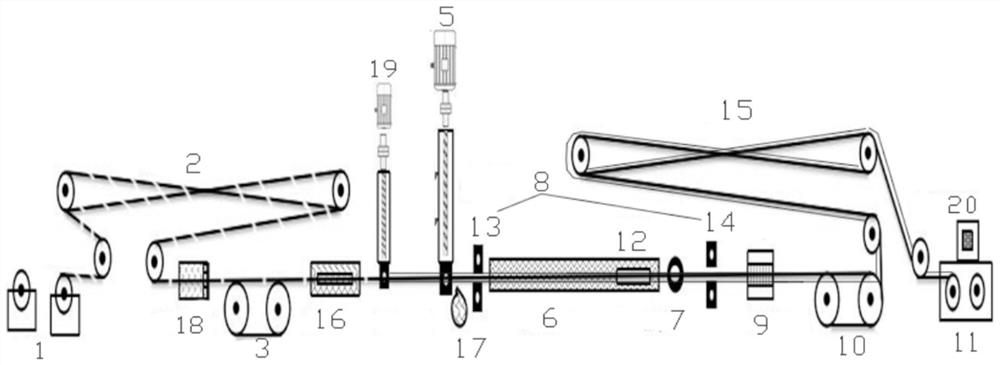

[0028] Example 2: RG6 coaxial cable foam core wire, the inner conductor with a diameter of 1.04mm is taken as the core body, and the front and rear pay-off racks of a production system for lifting the echo coaxial cable foam core wire are used The copper-clad steel is drawn and installed between the racks, and the first axis is started for initial production. The flow rate between the front pay-off rack and the rear pay-off rack is 180 / min to 150 m / min or 2000 / min at the active pay-off speed ~1200 / min, the storage core of the wire storage rack is at a maximum of ±500 meters, and the unwinding speed of the front and rear pay-off racks can reach and maintain a storage capacity of at least 3 minutes of continuous operation. After the conductor tension rack is down, it passes 1.02 The mm drawing die is stretched to 1.02mm by the front tractor, and the echo rate is adjusted to achieve the speed difference between the front pay-off frame and the rear pay-off frame. A frequency is 50H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com